Preparation method of anti-slip wear-resistant ceramic tile

A ceramic tile and anti-skid technology, applied in the field of ceramic tiles, can solve the problems of low surface friction coefficient of ceramic products, affecting the safe use of products, insufficient surface hardness, etc., and achieve good anti-skid and wear-resistant effect, low gloss and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing an anti-slip and wear-resistant ceramic tile, which mainly includes the following steps: (a) preparing a green body layer; (b) spreading an anti-slip and wear-resistant glaze on the green body layer to form an anti-slip and wear-resistant layer; (c) sintering;

[0034] The anti-slip and wear-resistant glaze is mainly prepared from the following raw materials in parts by mass: 90-110 parts of anti-slip and wear-resistant particles, 90-110 parts of printing paste and 0.2-0.4 parts of sodium tripolyphosphate;

[0035] The anti-skid and wear-resistant particles are mainly composed of the following components in parts by mass: SiO 2 60-70 parts, Al 2 o 3 20-30 parts, Fe 2 o 3 0.01-1 parts, TiO 2 0.1-2 parts, Na 2 O 1-5 parts, K 2 O 1-10 parts, MgO 0.01-1 parts, CaO 0.1-5 parts and ignition loss 0.1-2 parts.

[0036] The preparation method of the above-mentioned anti-slip and wear-resistant ceramic tiles firstly prepar...

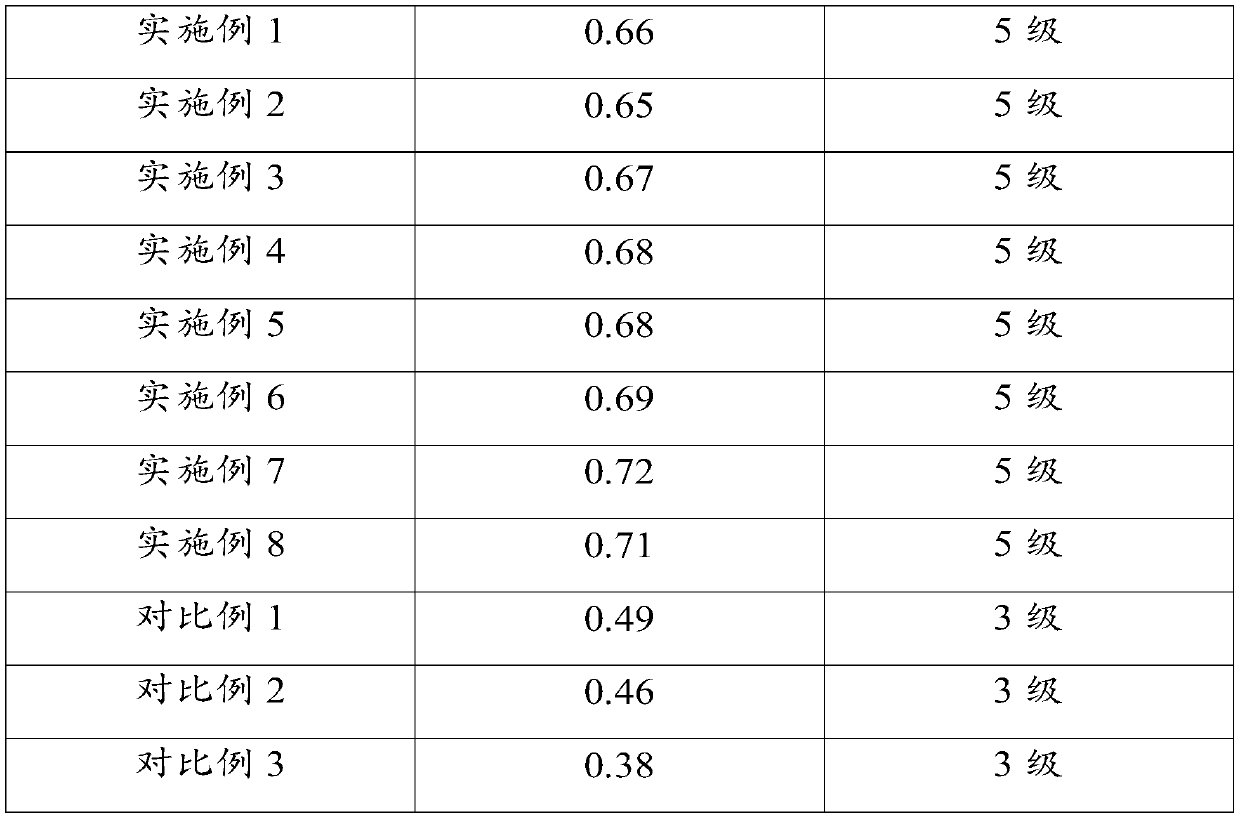

Embodiment 1

[0072] A preparation method of anti-slip and wear-resistant ceramic tiles, mainly comprising the following steps: (a) preparing a green body layer: (a1) raw materials for the green body are subjected to batching and dry ball milling for 10 hours to obtain slurry, and the fineness of the slurry is After passing through a 100-mesh sieve, the sieve residue is 5%;

[0073] (a2) The slurry is sieved after deironing, sieving, stale, and spray milling to obtain a blank. The particle gradation of the blank is 0 for 20 mesh and above, 20% for 20-40 mesh, and 20% for 20-60 mesh. 50% for mesh, 8% for less than 100 mesh, and 60-100 mesh for the rest;

[0074] (a3) Pressing and forming the blank by using a mold through a press to obtain the green body layer;

[0075] (b) spraying anti-slip and wear-resistant glaze on the body layer to form an anti-slip and wear-resistant layer;

[0076] The anti-slip and wear-resistant glaze is mainly prepared from the following raw materials in parts by...

Embodiment 2

[0080] A preparation method of anti-slip and wear-resistant ceramic tiles, mainly comprising the following steps: (a) preparing a green body layer: (a1) raw materials for the green body are subjected to batching and dry ball milling for 10 hours to obtain slurry, and the fineness of the slurry is After passing through a 100-mesh sieve, the sieve residue is 5%;

[0081] (a2) The slurry is sieved after deironing, sieving, stale, and spray milling to obtain a blank. The particle gradation of the blank is 0 for 20 mesh and above, 20% for 20-40 mesh, and 20% for 20-60 mesh. 50% for mesh, 8% for less than 100 mesh, and 60-100 mesh for the rest;

[0082] (a3) Pressing and forming the blank by using a mold through a press to obtain the green body layer;

[0083] (b) spraying anti-slip and wear-resistant glaze on the body layer to form an anti-slip and wear-resistant layer;

[0084] The anti-slip and wear-resistant glaze is mainly prepared from the following raw materials in parts by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com