A copper-composite magnesia-chrome brick and its manufacturing method

A technology for compounding magnesia-chromium bricks and magnesia-chromium bricks, applied in the field of refractory materials, can solve the problems of reduced beneficial components, uneven pore size, and good resistance to liquid slag penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

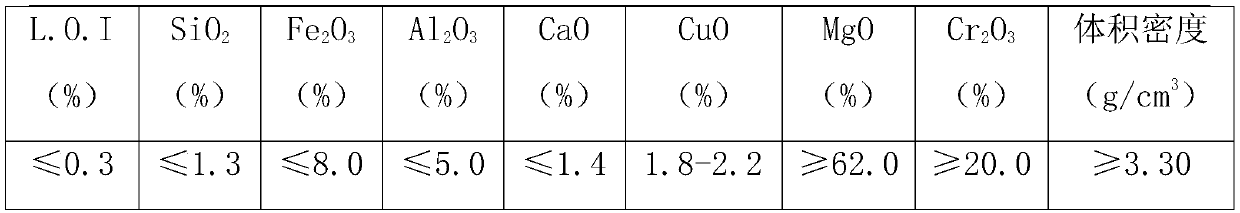

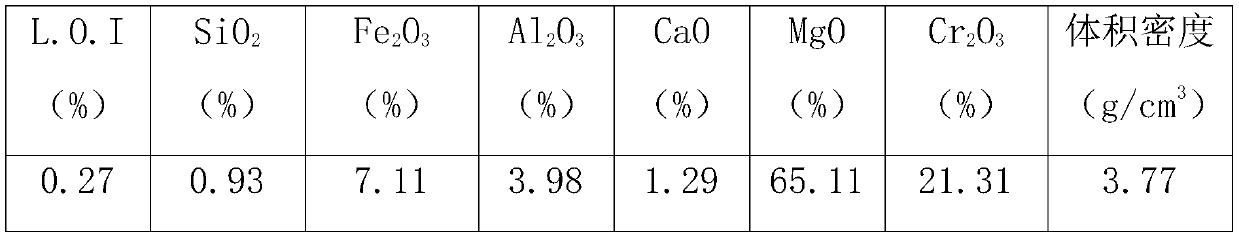

Embodiment 1

[0051] Copper-composite high-performance magnesia-chrome bricks, the proportion of raw materials by weight percentage is as follows: 8% of copper-composite magnesia-chrome synthetic sand with a particle size of 3-5mm, 27% of copper-composite magnesia-chrome synthetic sand with a particle size of 1-3mm, and a particle size of 0.088 -1mm copper composite magnesia-chrome synthetic sand 15%, 20 fused magnesia-chrome sand with a particle size of 3-5mm 1%, 20 fused magnesia-chrome sand with a particle size of 1-3mm 2%, 20 fused magnesia-chrome sand with a particle size of 0.088-1mm 2% of fused magnesia chrome sand, 6.5% of 20 fused magnesia chrome sand with a particle size of ≤0.088mm, 3% of 97 fused magnesia with a particle size of 3-5mm, 8% of 97 fused magnesia with a particle size of 1-3mm, grain size 6% of 97 fused magnesia with a diameter of 0.088-1mm, 14% of 97 fused magnesia with a particle size of ≤0.088mm, 5% of South African chrome concentrate with a particle size of ≤0.088...

Embodiment 2

[0085] A copper-composite high-performance magnesia-chrome brick is prepared from the following raw materials by weight percentage: 5% of copper-composite magnesia-chrome synthetic sand with a particle size of 3-5mm, 25% of copper-composite magnesia-chrome synthetic sand with a particle size of 1-3mm 10% of copper-composite magnesia-chrome synthetic sand with a particle size of 0.088-1mm, 2% of fused magnesia-chrome sand with a particle size of 3-5mm, 12% of fused magnesia-chrome sand with a particle size of 1-3mm, and a particle size of 0.088- 1mm 20 fused magnesia chrome sand 10%, particle size ≤ 0.088mm 20 fused magnesia chrome sand 11%, particle size 3-5mm 97 fused magnesia 1%, particle size 1-3mm 97 fused magnesia 2%, 4% of 97 fused magnesia with a particle size of 0.088-1mm, 10% of 97 fused magnesia with a particle size of ≤0.088mm, 4% of Indian chrome concentrate with a particle size of ≤0.088mm, 4% of composite additives, Sulfurous acid pulp waste liquid (additional) 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com