Preparation method of glass ball for vitrification of radioactive waste, product and application thereof

A technology for radioactive waste and glass balls, which is used in radioactive purification, nuclear engineering, etc., to prevent blockage, improve efficiency, and meet the effects of unpowered feed delivery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Preparation method of glass spheres of radioactive waste glass, including the following steps: fuse, double roller mold, knocking crushed, wrap, granular grade, grinding circle and acid polishing step.

[0046] Specific steps are as follows:

Embodiment 1

[0048] 1. Fuse:

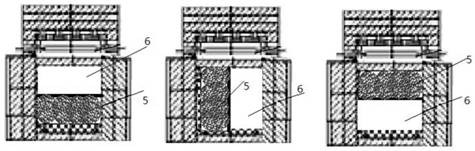

[0049] Put the ingredients from the feed port 1 to the electric kiln (see figure 1The glass liquid 6 is flowed out by the coke heat of the main molten electrode 2, and the glass liquid 6 is flowed from the discharge port 4 of the wavy feeder 3; the glass liquid 6 is observed, requiring the sample under the optical microscope, no visible bubble, no melery, No separation or devital phenomenon;

[0050] 2. Double Roll Mold Forming:

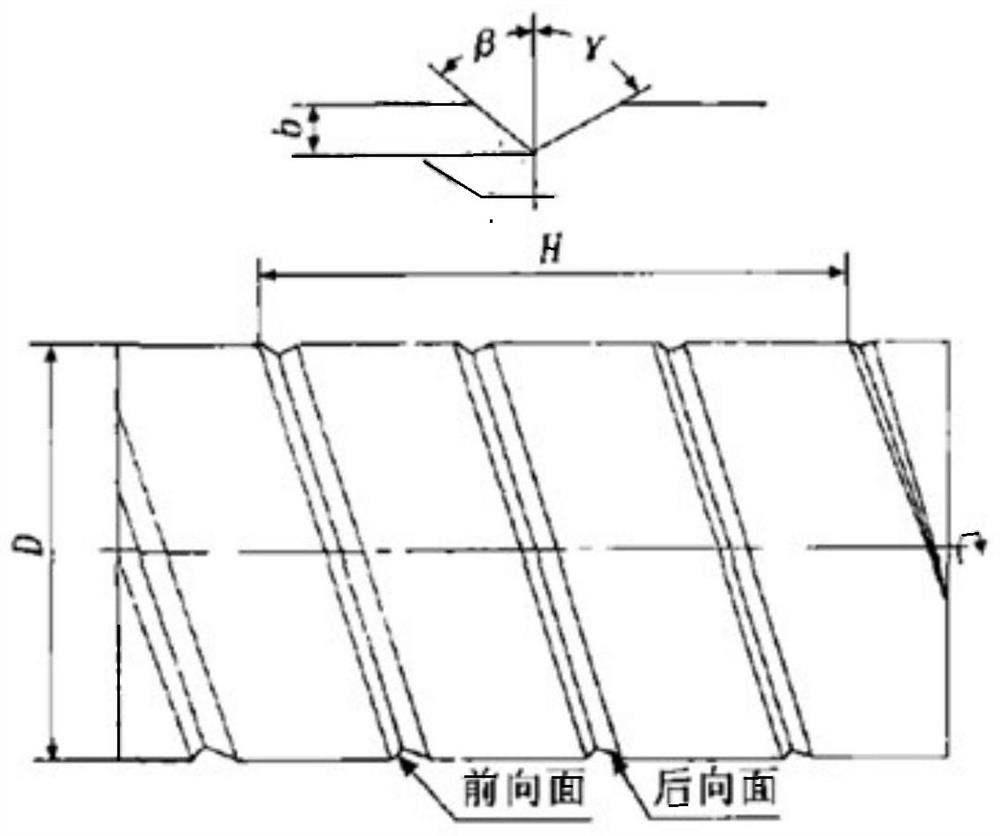

[0051] The fused glass liquid 6 is continuously flowed between the relative rotating double roller mold 7 by the feed channel discharge port 4 (see Figure 4 ), The double roller mold 7 has at least one roller having a single row or a plurality of concave pits; the glass-shaped concave pit; the glass liquid is passed closely to the opposite rotation of the double roller mold 7. In the numerous concave pit of the mold, the viscous liquid is converted to a plastic, and then transformed into a blank having a fixed shape (see Figure 4 , Figu...

Embodiment 2

[0059] Based on the first embodiment, in step 1, the wavy feed channel 3 refers to a channel of the cross-sectional shape is hollow, and the different cross-sectional position is set or / and several incompletely divided baffles in the longitudinal direction. 5; the glass liquid 6 flows through the baffle 5 of different angles to be disturbed, and the flow direction and speed are changed several times to avoid layering;

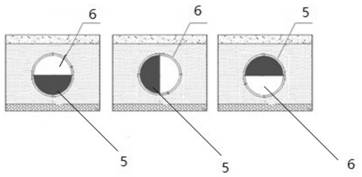

[0060] The cross-sectional shape of the wavy feed channel 3 can select a rectangle (see figure 2 ) Or / and circle (see image 3 ), Use refractory brickwork (brick gap with refractory mud filling) or refractory pouring overall molding, reducing the high temperature volatilization of volatile components by full sealing;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com