Silk printing-free light guide plate

A light guide plate and wire-free technology, which is applied in the direction of light guides, optics, optical components, etc., can solve the problem of uneven light output from the light guide plate, achieve uniform light output, fine dispersion, and improve the effect of uneven brightness and darkness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

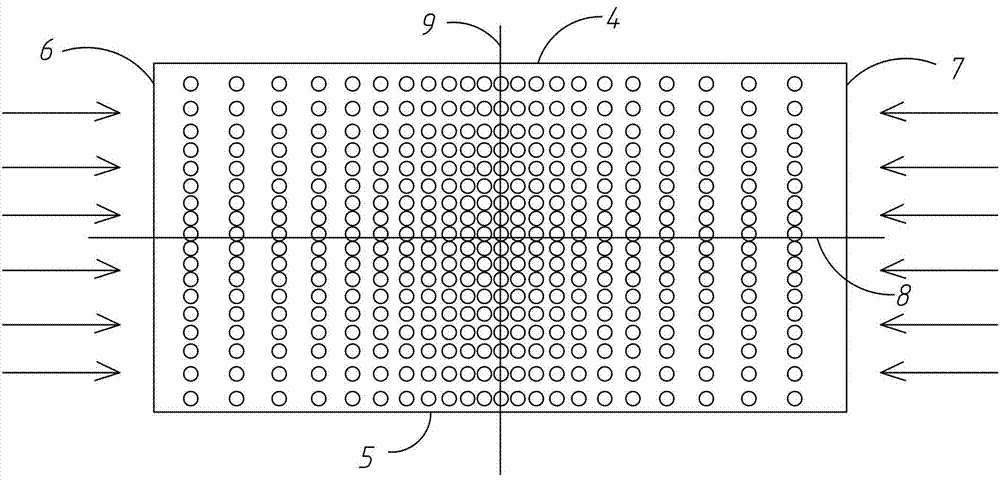

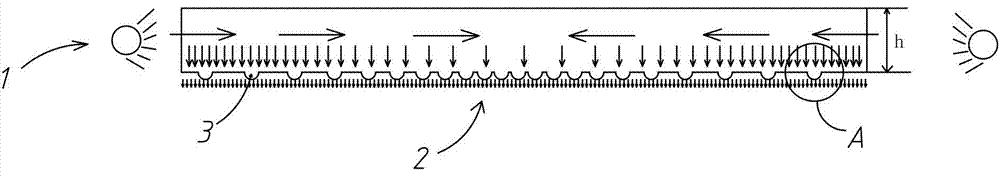

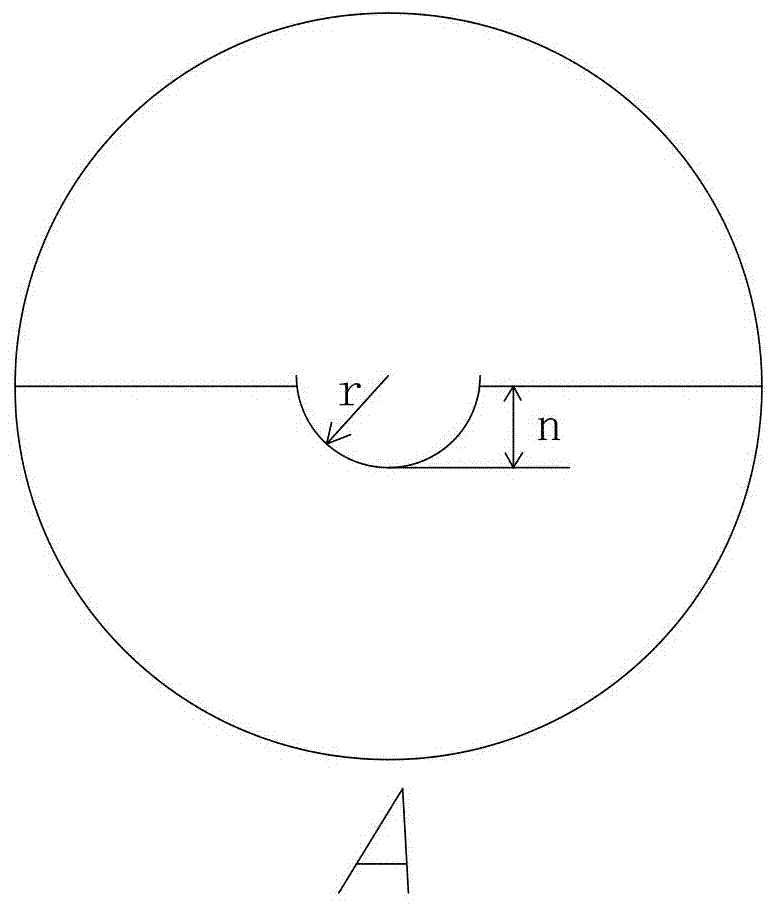

[0018] Such as Figure 1 to Figure 4 A silk-screen-free light guide plate is shown, the light guide plate has a light incident surface 1, a light exit surface 2 and a dot structure, the light incident surface 1 is arranged on the left and right sides of the light guide plate, and the light exit surface 2 is arranged on the The bottom surface of the light board, the dot structure is arranged on the light exit surface 2, the light exit surface 2 includes the upper side 4, the lower side 5, the left side 6, the right side 7, the upper side 4 and the lower side 5 The first central line 8, the second central line 9 of the left side 6 and the right side 7, the dot structure is made up of some hemispherical dots 3, and the dots 3 are from the upper side 4 to the first central line 8 gradually increases, the density of the dots 3 from the lower side 5 to the first centerline 8 gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com