Yeast repairing essence

An essence and yeast technology, applied in the field of skin care, can solve problems such as dependence and other side effects, skin discomfort, allergic reactions, etc., and achieve the effects of water absorption and moisture distribution, prevention of moisture distribution, and the preparation method is simple and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

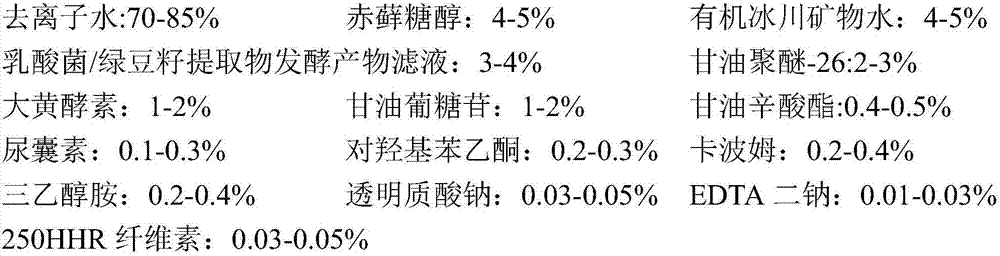

[0025] A kind of yeast restoration essence water, comprises the following components by weight percentage:

[0026]

[0027] A method for preparing yeast repair essence water, specifically comprising the following steps:

[0028] (1) Clean the required equipment 100L emulsification vacuum homogenizer, stainless steel barrel, stainless steel cup, and stainless steel spoon, and disinfect it for later use;

[0029] (2) Put the deionized water, disodium EDTA, allantoin, carbomer, and glyceryl polyether-26 in the above raw materials into the emulsification vacuum homogenizer and stir and heat up to 95°C to start homogenization, stirring The speed is controlled at 300r / min; the homogenization time is 5-8min, the homogenization speed is controlled at 3000r / min, and after the homogenization is completed, heat preservation and sterilization are carried out for 30min;

[0030] (3) Add erythritol, sodium hyaluronate, and 250HHR cellulose into the step (2), stir and dissolve, then eva...

Embodiment 2

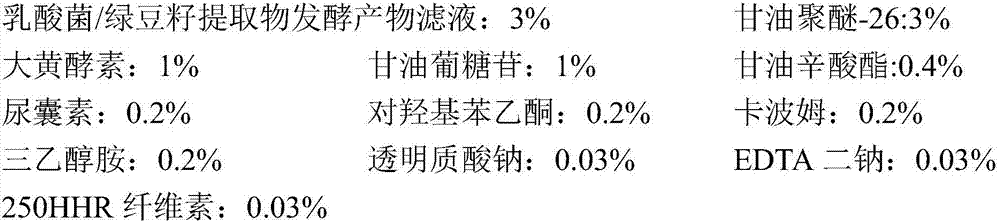

[0035] A yeast repair essence water, comprising the following components in optimal weight percentages:

[0036]

[0037] A method for preparing yeast repair essence water, specifically comprising the following steps:

[0038] (1) Clean the required equipment 100L emulsification vacuum homogenizer, stainless steel barrel, stainless steel cup, and stainless steel spoon, and disinfect it for later use;

[0039] (2) Put the deionized water, disodium EDTA, allantoin, carbomer, and glyceryl polyether-26 in the above raw materials into the emulsification vacuum homogenizer and stir and heat up to 95°C to start homogenization, stirring The speed is controlled at 300r / min; the homogenization time is 5-8min, the homogenization speed is controlled at 3000r / min, and after the homogenization is completed, heat preservation and sterilization are carried out for 30min;

[0040] (3) Add erythritol, sodium hyaluronate, and 250HHR cellulose into the step (2), stir and dissolve, then evacua...

Embodiment 3

[0045] A kind of yeast repair essence water, comprises following raw material weight components:

[0046]

[0047] A method for preparing yeast repair essence water, specifically comprising the following steps:

[0048] (1) Clean the required equipment 100L emulsification vacuum homogenizer, stainless steel barrel, stainless steel cup, and stainless steel spoon, and disinfect it for later use;

[0049] (2) 82.71kg of deionized water, 0.03kg of disodium EDTA, 0.2kg of allantoin, 0.2kg of carbomer, and glycerol polyether-26:2kg in the raw materials are put into an emulsification vacuum homogenizer and stirred and heated up to Homogenization starts after 95°C, and the stirring speed is controlled at 300r / min; the homogenization time is 5-8min, and the homogenization speed is controlled at 3000r / min. After the homogenization is completed, heat preservation and sterilization are carried out for 30min;

[0050](3) Add 4 kg of erythritol, 0.03 kg of sodium hyaluronate, and 0.03 k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com