Electric soldering iron smog removing system and electric soldering iron

A technology of electric soldering iron and power supply, which is applied in the direction of soldering iron, auxiliary equipment, metal processing equipment, etc. It can solve the problems of inability to reduce the speed, delay in eliminating smoke, waste of power resources, etc., and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

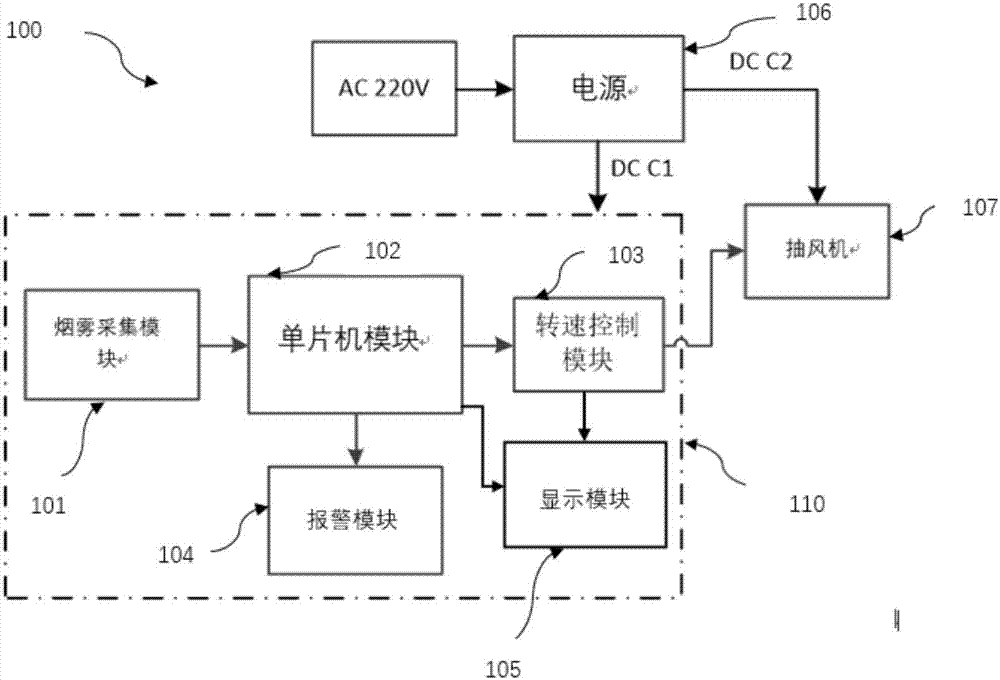

[0019] refer to figure 1 and figure 2 , this embodiment provides an electric soldering iron smoke removal system 100, including a power supply 106, an exhaust control module 110, and an exhaust fan 107;

[0020] The ventilation control module 110 further includes: a smoke collection module 101 , a single-chip microcomputer module 102 , a rotation speed control module 103 , an alarm module 104 and a display module 105 .

[0021] The power supply 106 is directly connected to the alternating current AC220V, which can convert the alternating current into direct current, and provide DC C1 to supply power to the exhaust control module 110 and DC C2 to supply power to the exhaust fan 107; in this embodiment, the power supply 106 can also be provided with a button switch, To make it convenient to turn off the power supply in advance when the power supply 106 is disconnected from the alternating current and prevent forgetting to unplug the power supply 106 so that the electric solder...

no. 2 example

[0037] This embodiment provides an electric soldering iron, which includes the electric soldering iron body and the electric soldering iron smoke removal system described in the first embodiment.

[0038] Compared with the prior art, the technical solution of the present invention has the following advantages:

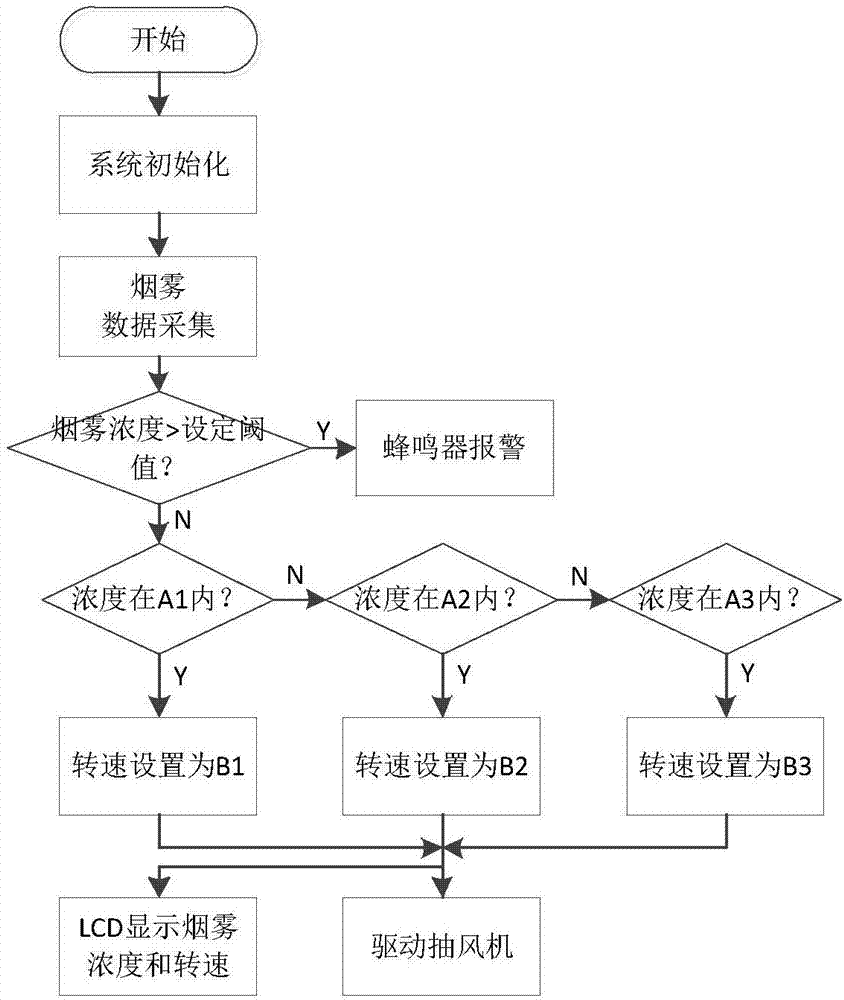

[0039] The electric soldering iron smoke removal system uses a single-chip microcomputer module 102 to analyze the smoke concentration, and stores it in the single-chip microcomputer module 102 according to the set smoke concentration threshold value. When the set threshold value is exceeded, the single-chip microcomputer module 102 controls the alarm module to give an alarm. The single-chip microcomputer module 102 is set with a smoke concentration interval, and when the collected smoke concentration falls into the corresponding smoke interval, it will send information to the speed control module 103 to select an appropriate speed to drive the exhaust fan 107 to extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com