A particulate removal device for brittle board scribers

A technology for brittle substrates and scribes, applied in glass cutting devices, fine working devices, working accessories, etc., to achieve excellent removal efficiency and rapid dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, an embodiment of the present invention will be described in more detail with reference to the attached drawings.

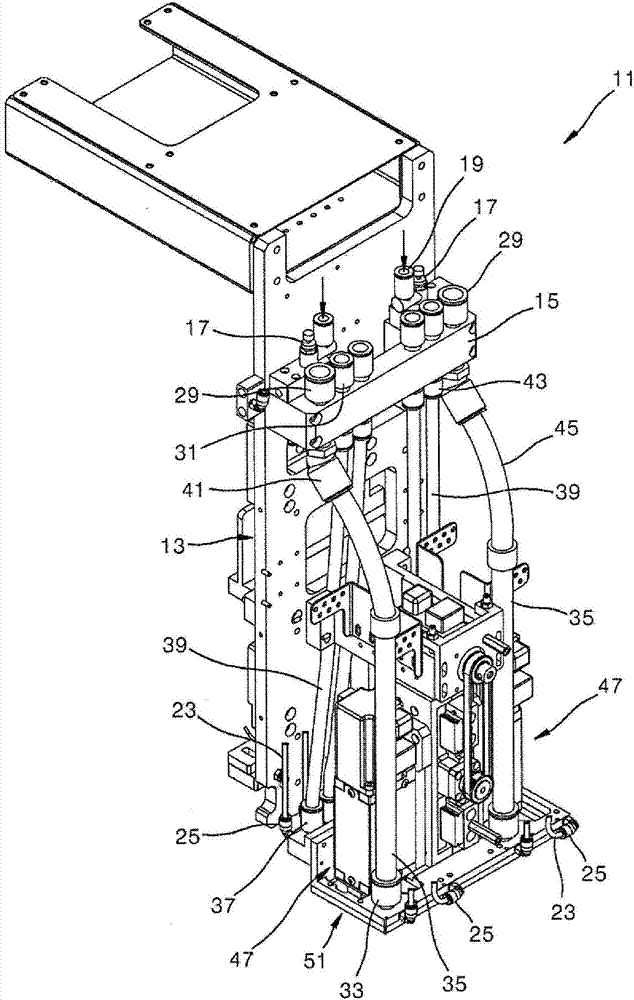

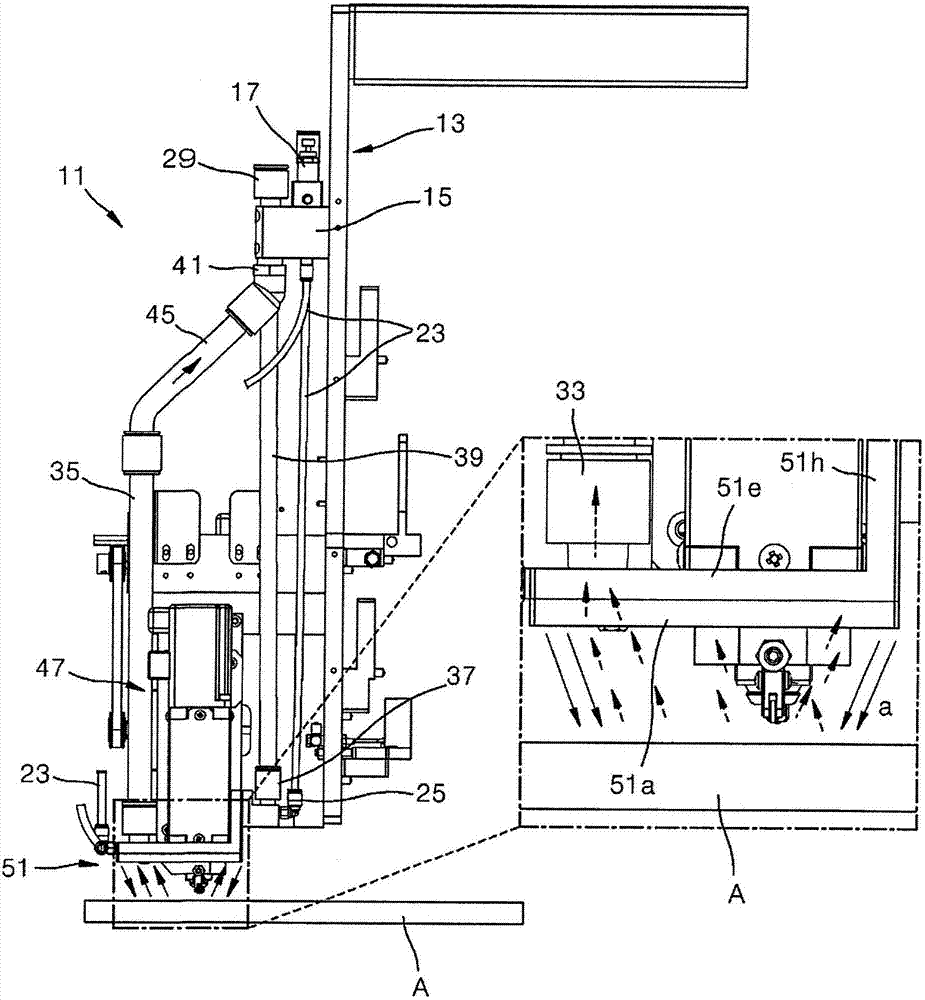

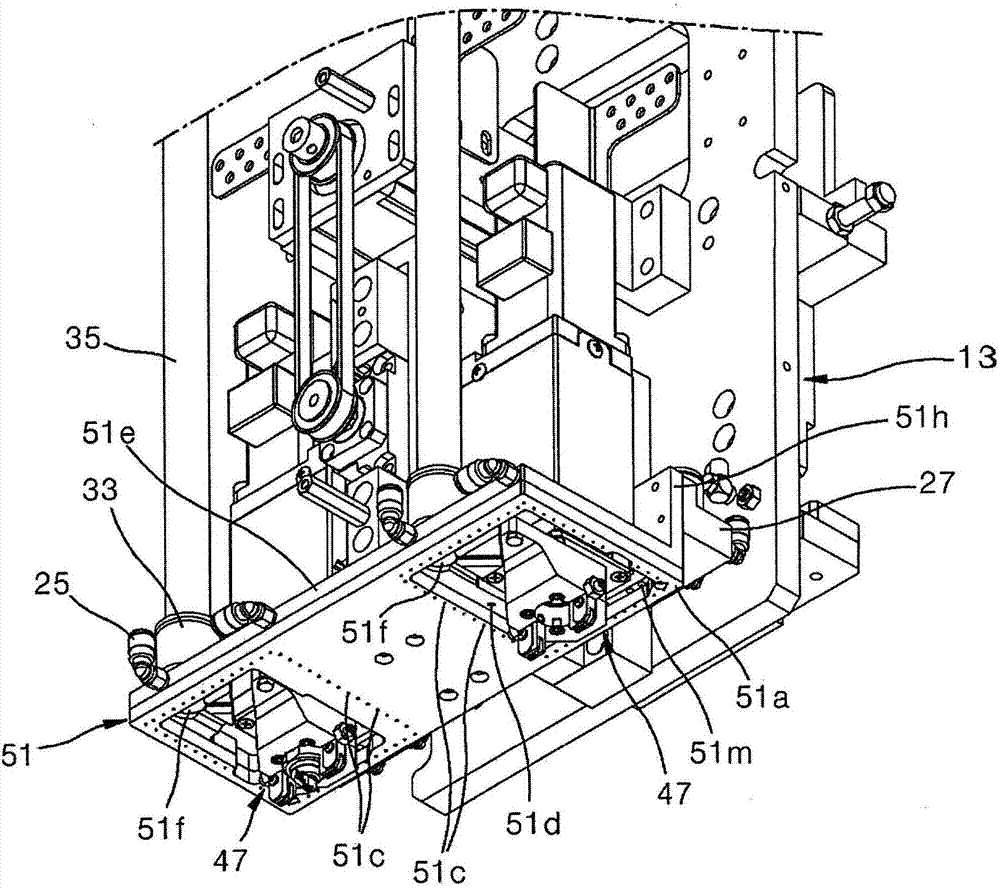

[0032] figure 1 It is a perspective view showing an overall state of a scriber to which a dust removal device for a brittle substrate scriber according to an embodiment of the present invention is applied. figure 2 for illustration figure 1 A side view of the operating principle of the dust removal device for brittle substrate scribers shown, image 3 for illustration figure 1 A diagram showing the structure of the dust lifter of the dust removal device for a brittle substrate scriber.

[0033] The dust removal device for the brittle substrate scriber of this embodiment is installed at the lower part of the head 47 constituting the scriber 11, sucks in the dust generated during scribing and discharges it to the outside, and has the following features: it can form air surrounding the scribing wheel In particular, it is possible to adjust th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com