High-efficiency automated latex distributing and supplying system

A technology of feeding system and batching system, which is applied in the field of efficient automatic latex batching feeding system, can solve the problems of high batching error rate, insufficient automation, and inability to meet the requirements, and achieves the effect of high efficiency, accurate batching, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further described below in conjunction with accompanying drawing:

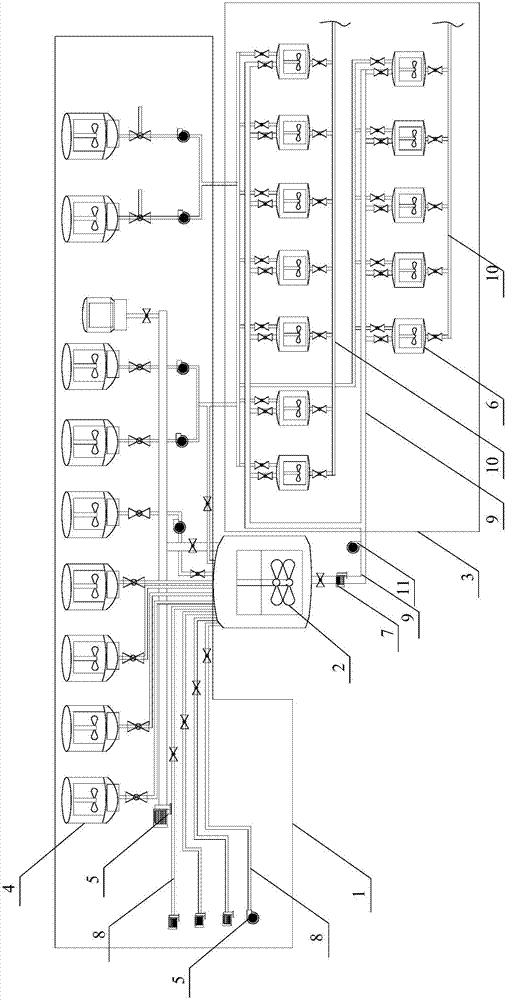

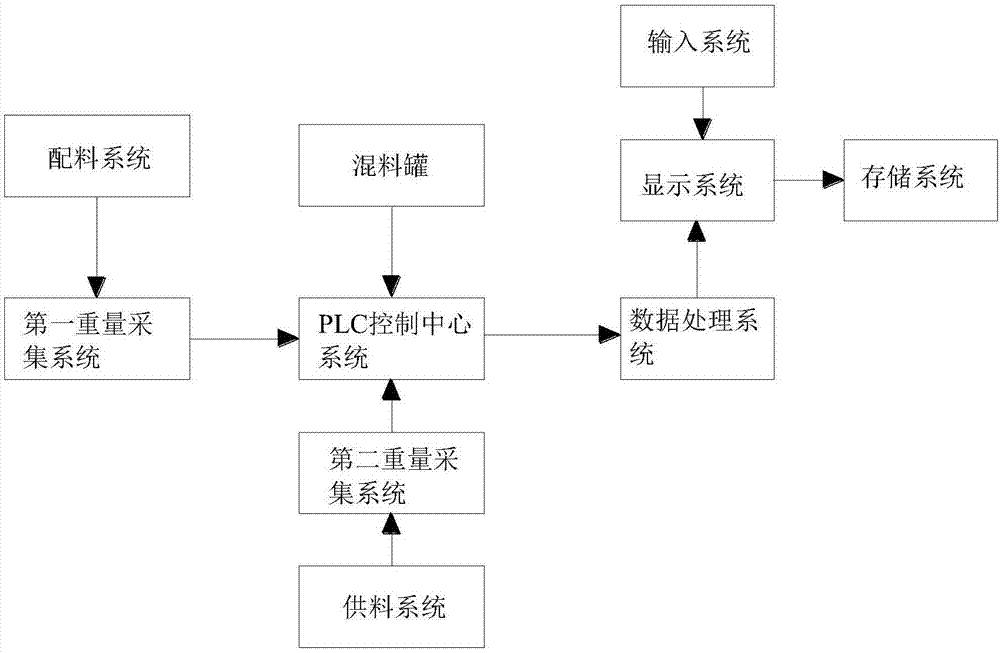

[0015] A high-efficiency automatic latex batching and feeding system, including a batching system 1, a mixing tank 2, a feeding system 3, a PLC control center system, a first weight acquisition system, a second weight acquisition system, a data processing system, a display system, and an input system and storage system, the batching system 1 includes several raw material tanks 4 and batching pipes 8 connected to the raw material tanks 4, the batching pipes 8 are equipped with feed pumps 5 and control valves, and the batching pipes 8 are connected to the mixing tank 2 Connected above, the feed system 3 includes a feed pipe 9, several storage tanks 6 and a discharge pipe 10, the feed pipe 9 is connected to the bottom of the mixing tank 2, and a feed pump 7 is installed on the feed pipe 9 And blower fan 11, described storage tank 6 is communicated with feeding pipe 9 by pipeline, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com