A kind of anti-collapse polymer mud powder and its preparation method and application

A polymer, anti-collapse type technology, applied in the field of pile foundation wall mud material, can solve the problems of limited application value, small application scope, serious environmental pollution of products, etc., to save labor and material costs, promote recycling times, The effect of increasing the compactness of the mud

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Application project: Newly built Lianzhen Railway (Huai'an section), the pile foundation construction technology is rotary drilling and underwater grouting, the pile length is 50-60 meters, the pile diameter is 1 meter, and the water-sensitive geology is concentrated in 15m-25m. layer of silt. A third-party test shows that, compared with bentonite mud, the application of the anti-slump polymer mud protection wall of the present invention to form a pile can increase the bearing capacity of the friction pile foundation by more than 30%, and the quality of the pile can meet the design requirements.

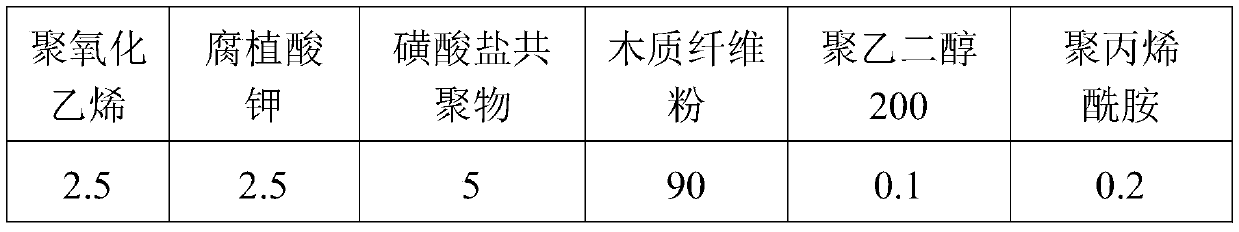

[0026] The preparation composition of the anti-slump polymer mud powder is shown in Table 1, and the application performance of the prepared mud is shown in Table 2.

[0027] Table 1 Weight composition of anti-collapse polymer mud material (unit: part)

[0028]

[0029] Table 2 Application properties of prepared mud

[0030] Amount of mud powder (ton / 100m 3 wat...

Embodiment 2

[0032]Application project: newly built Lianzhen Railway (Huai'an section), the pile foundation construction technology is reverse circulation drilling underwater injection, the pile length is 51-55 meters, the pile diameter is 1.5 meters, and the water-sensitive geology is concentrated in 10m-22m meters, mainly layer of silt. Third-party testing shows that, compared with bentonite mud, the application of anti-slump polymer mud to form piles can increase the bearing capacity of friction pile foundations by more than 30%, and the quality of piles meets the design requirements.

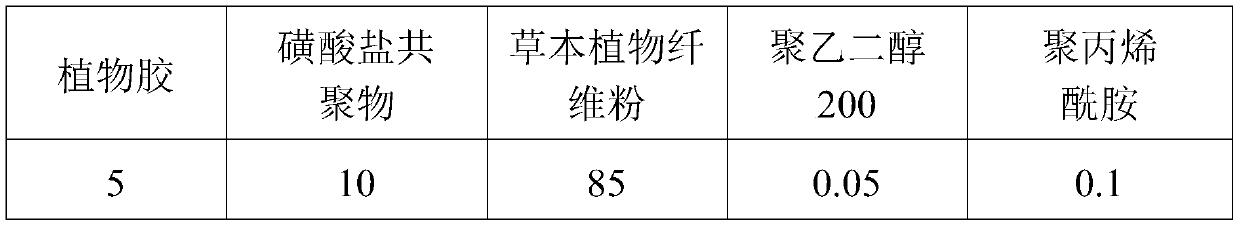

[0033] The composition of the anti-slump polymer mud powder is shown in Table 3, and the application performance of the prepared mud is shown in Table 4.

[0034] Table 3 Composition of anti-collapse polymer mud material (unit: part)

[0035]

[0036] Table 4 Application properties of prepared mud

[0037] Amount of mud powder (ton / 100m 3 water)

Embodiment 3

[0039] Application project: Shanghe-Hangzhou Railway (Anhui section), the pile foundation construction technology is rotary drilling and underwater grouting, the pile length is 52-56 meters, the pile diameter is 1 meter, and the water-sensitive geology is concentrated in 15m-20m and 26m-33m meters, mainly for strongly weathered rock formations and silt layers, and the quality of the piles meets the design requirements.

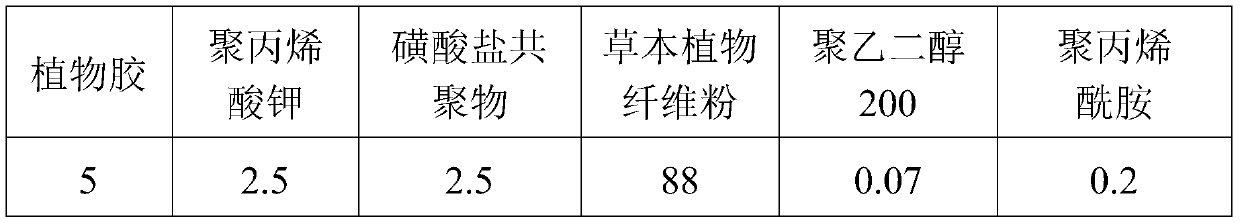

[0040] The composition of the anti-slump polymer mud powder is shown in Table 5, and the application performance of the prepared mud is shown in Table 6.

[0041] Table 5 Composition of anti-collapse polymer mud material (unit: part)

[0042]

[0043] Table 6 Application properties of prepared mud

[0044] Amount of mud powder (ton / 100m 3 water)

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com