Complete equipment for producing xylitol and arabinose by directly utilizing microbiological fermentation method

A microbial fermentation method, arabinose technology, applied in fermentation and other directions, can solve the problems of large investment in oxidation process, high production cost, high energy consumption, etc., and achieve the effect of improving overall competitiveness, improving product quality and reducing product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

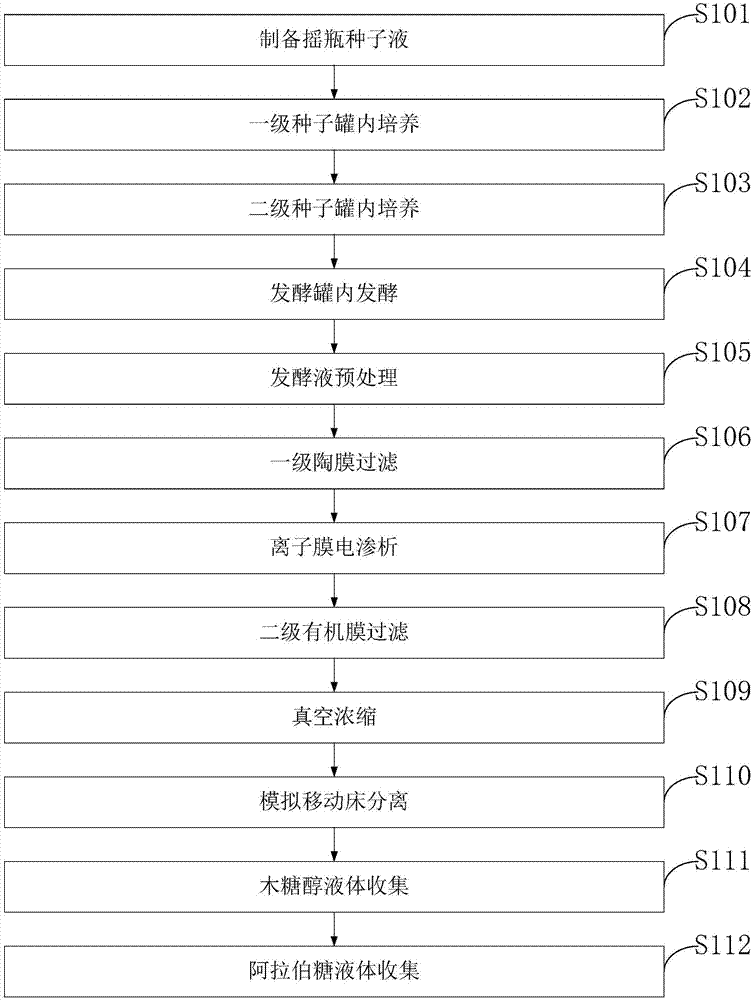

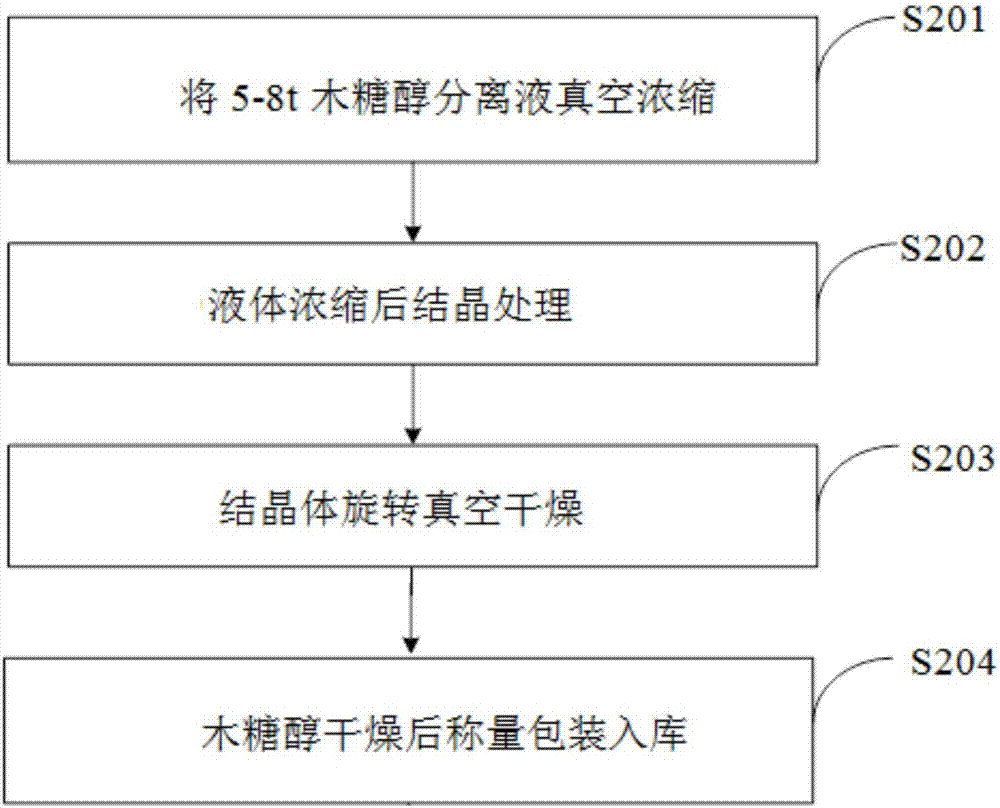

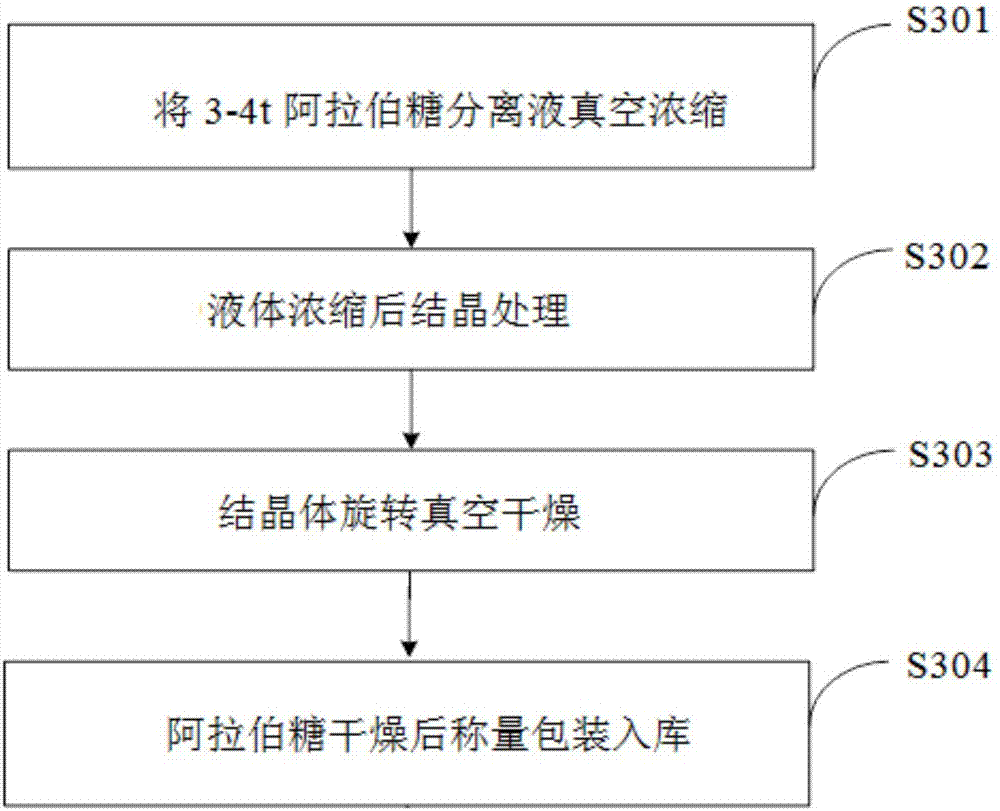

[0068] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0069] The structure of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0070] The complete set of equipment for producing xylitol and arabinose directly using the microbial fermentation method provided by the embodiment of the present invention uses corn cob hydrolyzate as the starting material and highly tolerant yeast as the carrier to pass through primary and secondary seeds Cultivation, fermenter culture transformation, convert xylose into xylitol under the conditions of 36°C and pressure 0.02MPa, and at the same time convert mannose, galactose and glucose in the hydrolyzate into biological oxidoreductase, only catalyze xylose -CHO in the conversion to -CH 3 Oh.

[0071] In the embodiment of the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap