Immersed oxygen lance continuous converting inclined metallurgical furnace

An immersed metallurgical furnace technology, applied in the field of continuous blowing metallurgical furnaces, can solve the problems of low cost, complex process, low investment, etc., and achieve the effects of long service life, avoiding low-altitude pollution and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

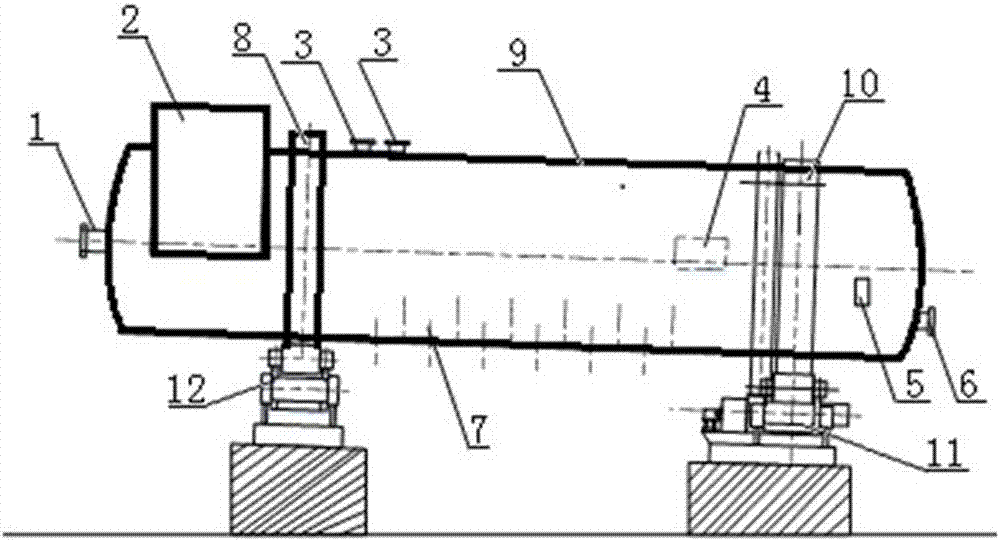

[0015] A submerged oxygen lance continuous blowing inclined metallurgical furnace, including a furnace body 9, a bracket 12, a rolling ring sleeve 8, a gear ring sleeve 10, a driving device 11, and an oxygen lance 7, wherein the furnace body 9 is a rotatable inclined cylinder The furnace has a furnace cavity inside, the flux port 3 is located on the top of the furnace body 9, the hot material port 1 is located on the side wall of the furnace body 9 away from the installation plane, and the cold material port 4 is located on the side of the furnace body 9 close to the installation plane On one side, the slag discharge port 5 is located below the side of the furnace body 9 close to the installation plane, the copper discharge port 6 is located on the side end wall of the furnace body 9 close to the installation plane, and the top of the furnace body 9 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com