Needle penetrating accessory of needle thread roll

A needle thread rolling and needle threading technology, which is applied in the field of needlework, can solve the problems of not fast, the tail end is not strong enough, and the difficulty of threading, etc., and achieve the effect of simple and scientific structure, convenient storage and storage, and great promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

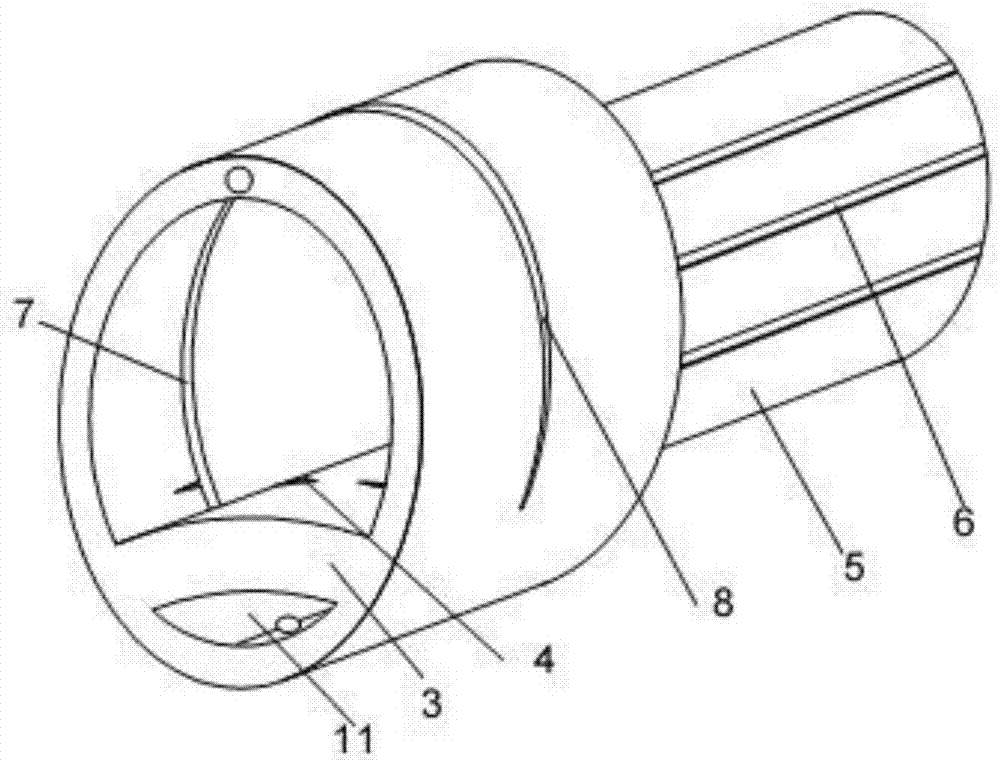

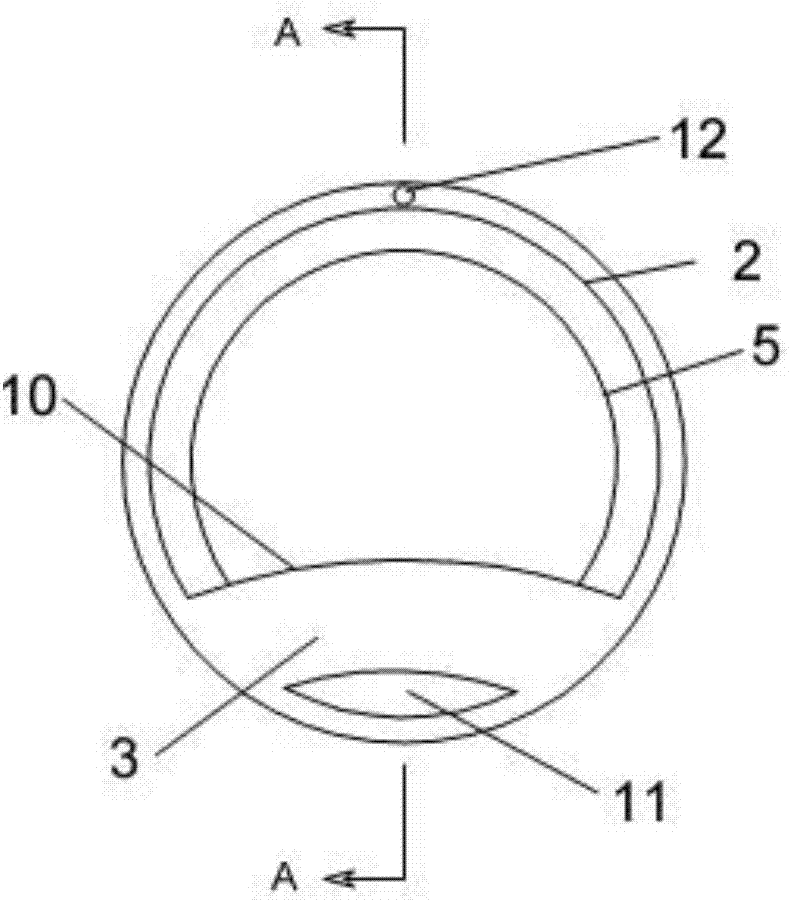

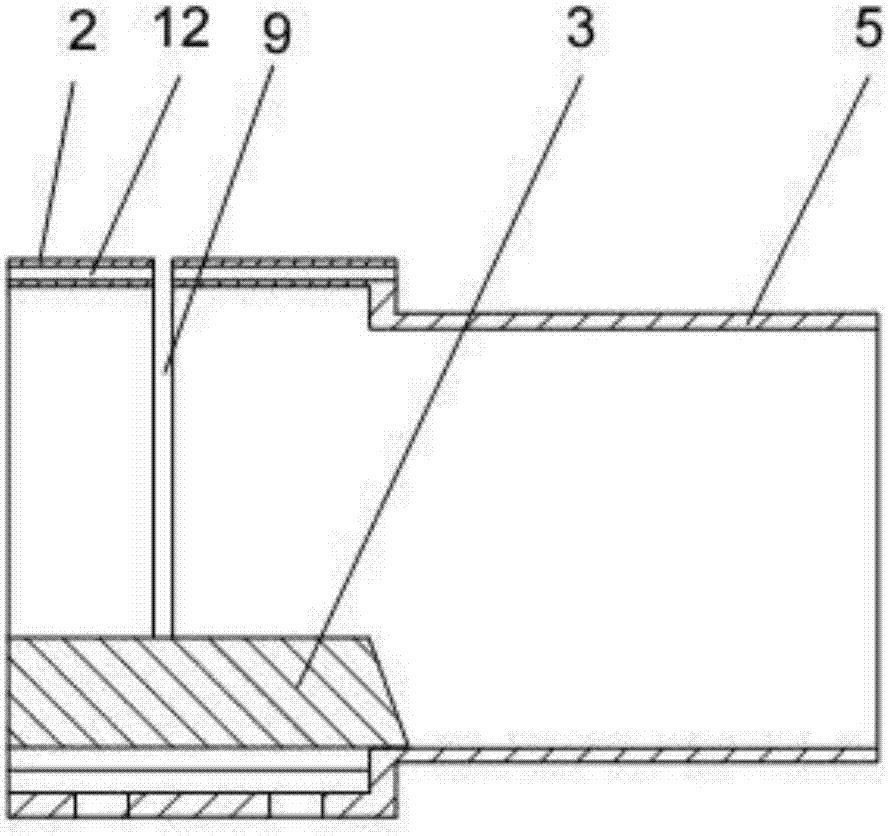

[0032] see Figure 1 to Figure 6, the needle threading accessory 1 of the needle thread roll of the present embodiment comprises an annular hollow needle threading cylinder 2, and a side part of the needle threading cylinder 2 inner wall is provided with a soft rubber strip 3 supporting a pinhole 34 laid flat; the surface of the soft rubber strip 3 There is a horizontal shallow groove 4 that provides positioning and limiting functions for the needle thread 32; the needle threading cylinder 2 is provided with a semi-circular slot 9 above the horizontal shallow groove 4 for the needle thread 32 to pass through and the needle thread 32 is close to the horizontal shallow groove 4 , the left side of the semi-annular slot 9 is the thread inlet slot 7, the right side of the semi-annular slot 9 is the fixed slot 8 for 32 needle threads, and the tail end of the fixed slot 8 for the 32 needle threads is a "" V"-shaped groove; for the needle threading accessories of the needle thread ree...

Embodiment 2

[0036] see Figure 1 to Figure 6 , in order to prevent the tiny sewing needles 33 from being accommodated and lost, and to cut off the needle thread 32 conveniently, so that the threading action can be carried out more easily and efficiently. This embodiment is further improved on the basis of Embodiment 1. The wall of the needle cylinder 2 is provided with a vertically arranged needle hiding hole 1234 , and the shape and size of the needle hiding hole 1234 matches the shape and size of the sewing needle 33 . The side wall of the wire inlet groove 7 is provided with a V-shaped secant groove 14, and the inner wall of one side of the V-shaped secant groove 14 has a cutting edge.

Embodiment 3

[0038] see Figure 7 ~ Figure 8 , in order to make the needle threading accessories of the needle thread roll more stable when threading the needle, prevent it from swinging left and right, and improve the efficiency of needle threading, this embodiment is further improved on the basis of Embodiment 1 or 2. The needle threading accessories of the needle thread roll also include anti-threading A planar support platform 13 that shakes when the needle is used. The bottom of the planar support platform 13 is a plane, and the upper part is an arc-shaped concave surface 15. The arc-shaped concave surface 15 matches the shape and size of the outer wall of the needle cylinder 2 on the side close to the soft rubber strip 3. The arc-shaped concave surface 15 is provided with two raised positioning columns 16, and the wall part of the side of the needle cylinder 2 provided with the soft rubber strip 3 is provided with a positioning hole 17 matched with the positioning column 16 to be inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com