Air cushion type double-mold slurry shield machine and control method thereof

A technology of air cushion type and shield machine, which is applied in the direction of earth drilling, mining equipment, tunnels, etc. It can solve the problems of surface subsidence, impact, and large pressure fluctuations in muddy water tanks, so as to avoid subsidence and ensure reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

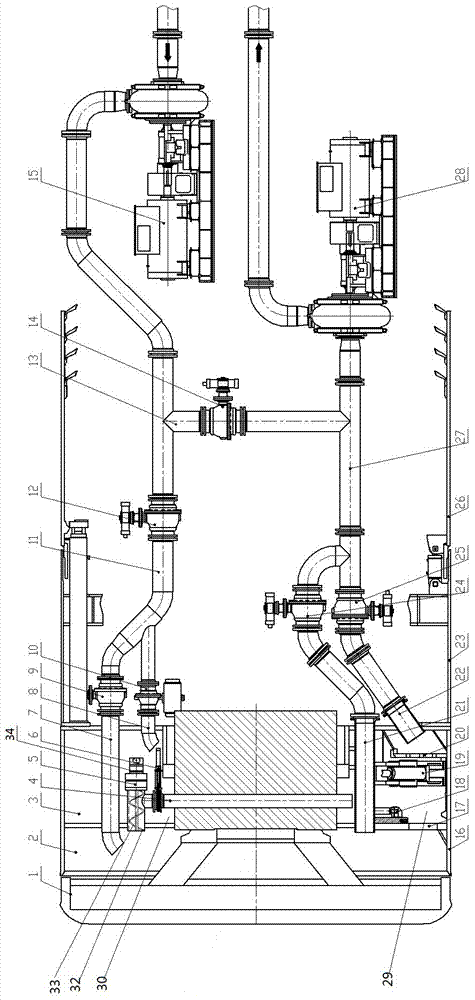

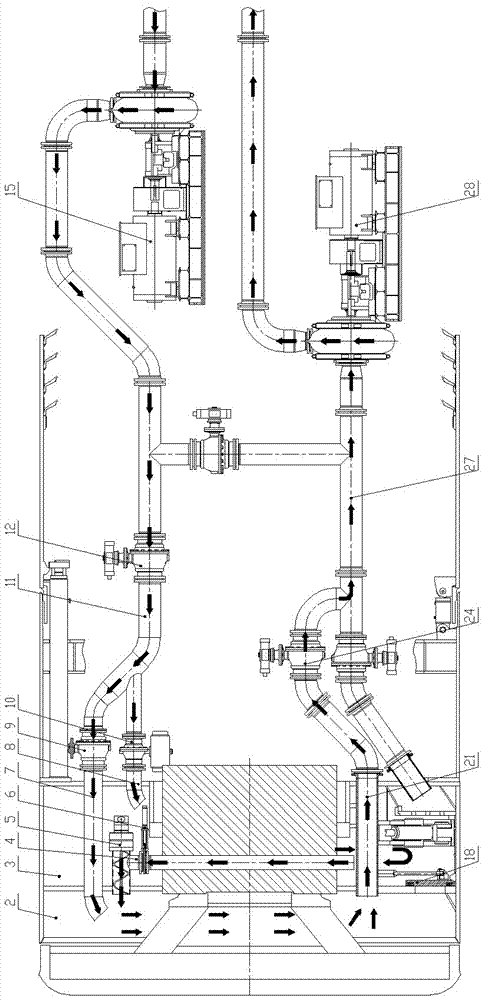

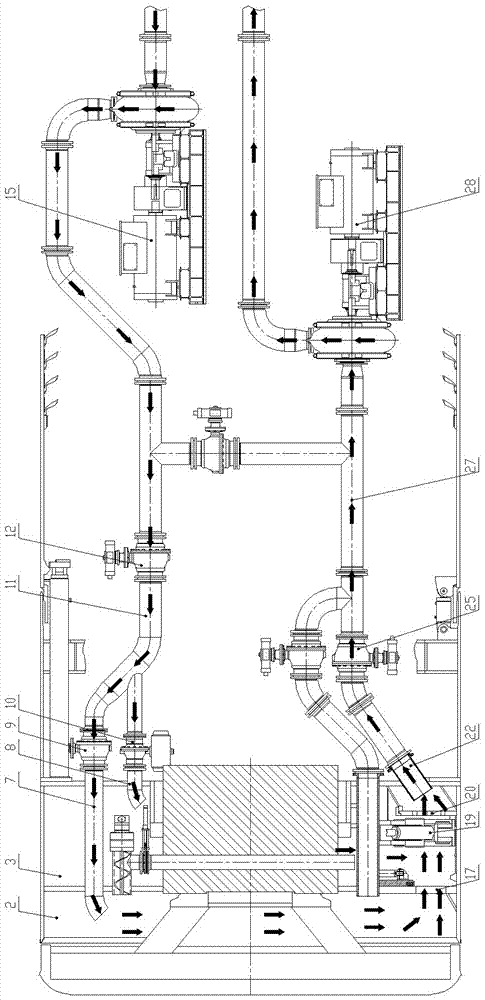

[0017] An air-cushion double-mode slurry shield machine and its control method according to the present invention will be further described below in conjunction with the accompanying drawings.

[0018] like figure 1 , figure 2 and image 3 As shown, in the air-cushion double-mode muddy water shield machine described in the present invention, the front end of the equipment is a cutter head 1, the muddy water bin 2 is behind the cutter head 1, the air cushion bin 3 is behind the muddy water bin 2, and the air cushion bin 3 There is a mud door 17 that can be opened and closed at the bottom between the mud tank 2, the lower part of the air cushion tank 3 is a mud water cavity 29, and the upper part is a high-pressure air cavity 30. The air cushion tank 3 is provided with an air cushion connecting pipe 4, and the air cushion connecting pipe 4 The upper port of the air cushion connecting pipe 4 stretches into the high-pressure air cavity 30, and the lower port of the air cushion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com