Heat exchanger and heat exchange module

A technology of heat exchangers and heat exchange tubes, which is applied in the direction of indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problem that the heat exchanger space is not used effectively, and achieve convenient transportation and assembly The effect of simplicity, cost reduction, and increased heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

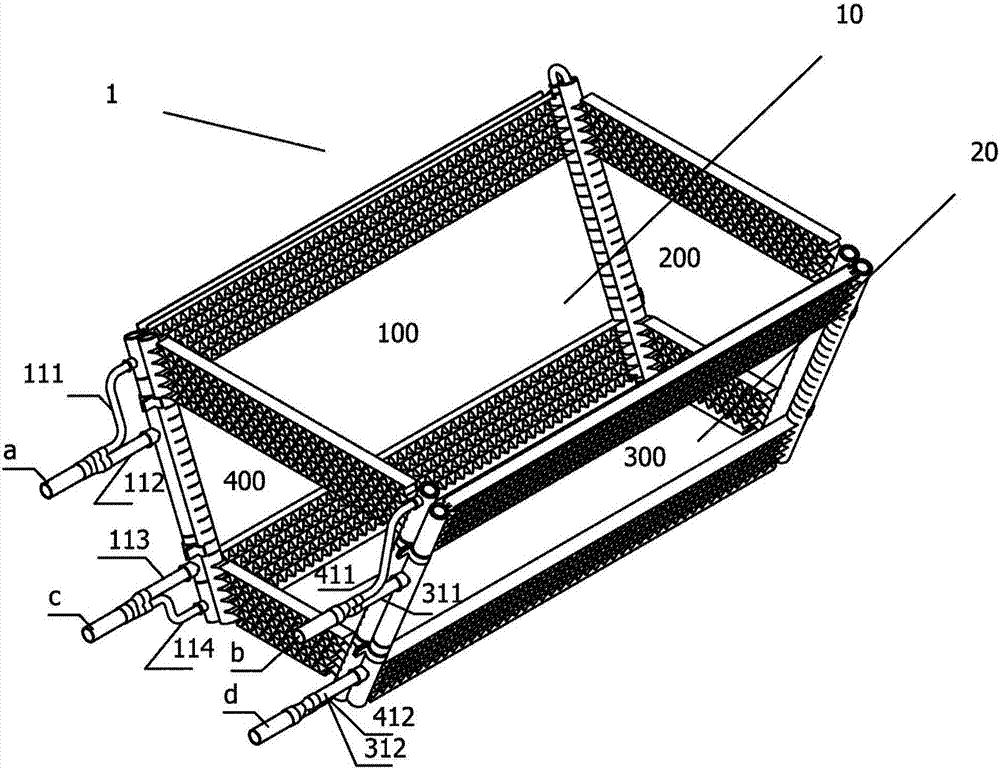

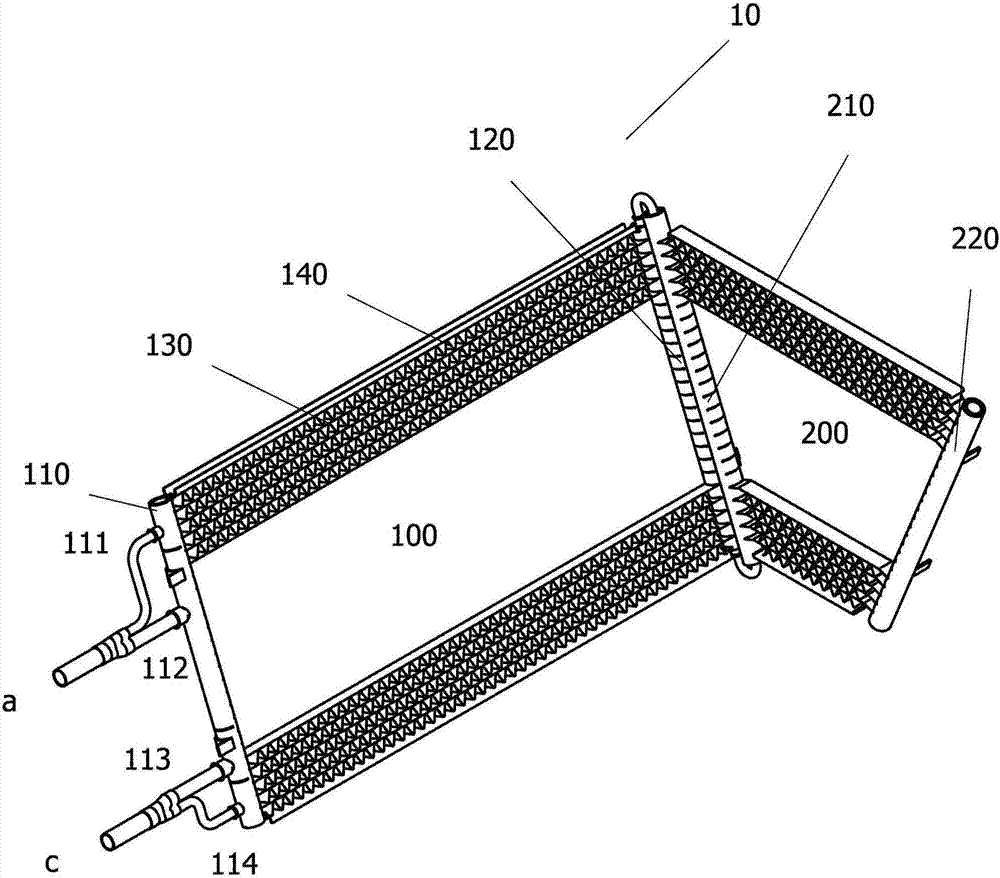

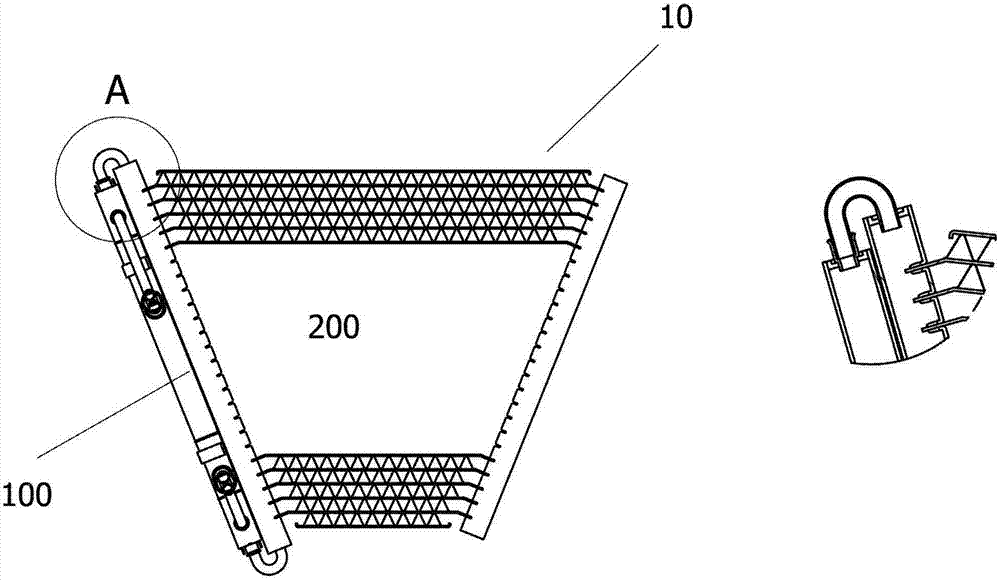

[0045] Below will pass embodiment, and in conjunction with appendix Figure 1-14, the technical solution of the present invention will be further specifically described. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0046] It should be understood that the terms first, second, third, fourth, etc. used in the description are not intended to arrange related elements in sequence, but to distinguish related elements, and thus do not limit the present invention. The exemplary descriptions of side heat exchangers, main heat exchangers or rectangular heat exchangers and trapezoidal heat exchangers do not constitute limitations of the present invention, but description...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com