Detection box used for detecting ice thrust and ice pulling destruction of reservoir icing for water construction and detection method thereof

A detection box and thrust technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of long time and high consumption, and achieve convenient use, good application prospects and ingenious structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

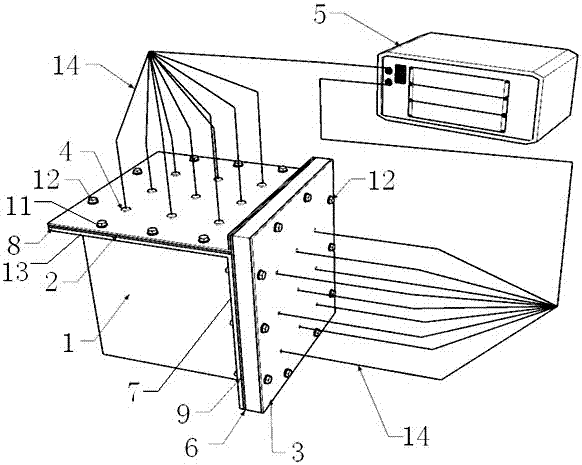

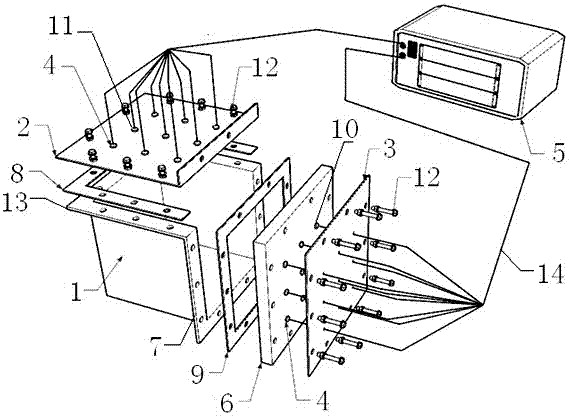

[0029] Embodiment 1: see figure 1 , 2, a detection box for detecting ice thrust and ice pullout damage of water conservancy buildings due to freezing of reservoirs, used to detect ice thrust and ice pullout force of a test material plate 6 made of rigid materials, including ice Liquid sink 1, the top and vertical side of the sink 1 are designed to be open, the top opening of the sink 1 is equipped with a top plate 2, and the opening of one side of the vertical surface is provided with a test material plate 6, and the test material plate 6 is fixed by The plate 3 is fixed on the water tank 1, and the top plate 2 and the surrounding of the fixed plate 3 are sealed with the water tank 1. The top plate 2 and the test material plate 6 are equipped with horizontally and vertically arranged multi-row and multi-column pressure sensors 4, pressure sensors 4 Communication connection with the signal receiver 5 through the data transmission line, the top opening of the detection box 1, a...

Embodiment 2

[0031] see figure 1 , 2 , a detection box for detecting ice thrust and ice pull damage of water conservancy buildings due to freezing of reservoirs, used to detect ice thrust and ice pull force of test material plate 6 made of elastic material, this embodiment and embodiment 1 The difference is that: the test material plate 6 is provided with nine passing holes I10 in three rows and three columns, wherein, two passing holes I10 are selected in each row, and there are six passing holes 10 in total, and the distance between the bottom of the six passing holes I10 is tested The material plate 6 is 2-5 mm away from the side of the water tank 1. Pressure sensors 4 are installed in the six passage holes I10. The detection end of the pressure sensor 4 is in contact with the bottom of the passage hole I10. The detection end of the sensor 4 is in contact with the fixed plate 3 .

Embodiment 3

[0033] see figure 1 , 2 , a detection method for detecting the ice thrust of water conservancy buildings and the detection box of ice pull damage caused by freezing of reservoirs. The test material board in this embodiment is polyurethane rigid foam, and the ice resistance it withstands under the condition of slow cooling is tested. Thrust and anti-ice pull damage

[0034] Specific detection method:

[0035] The size of the water tank 1 is 30cm*40cm*40cm (length*width*height). The water tank 1, the top plate 2, and the fixing plate 3 are all made of stainless steel with a thickness of 5mm. The test material plate 6 is polyurethane rigid foam (thickness 8cm, density 70Kg / m2) sprayed with polyurethane waterproof layer (thickness 1mm) on the outer layer 3 ).

[0036] Install the side sealing strip 9, test material plate 6 (polyurethane waterproof layer facing the water tank), fixing plate 3, and pressure sensor 4 on the water tank 1 in sequence through fixing bolts, of which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com