Fool-proof test equipment and method

A technology of testing equipment and testing methods, applied in the field of testing, can solve the problems of inconvenient follow-up process and market introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

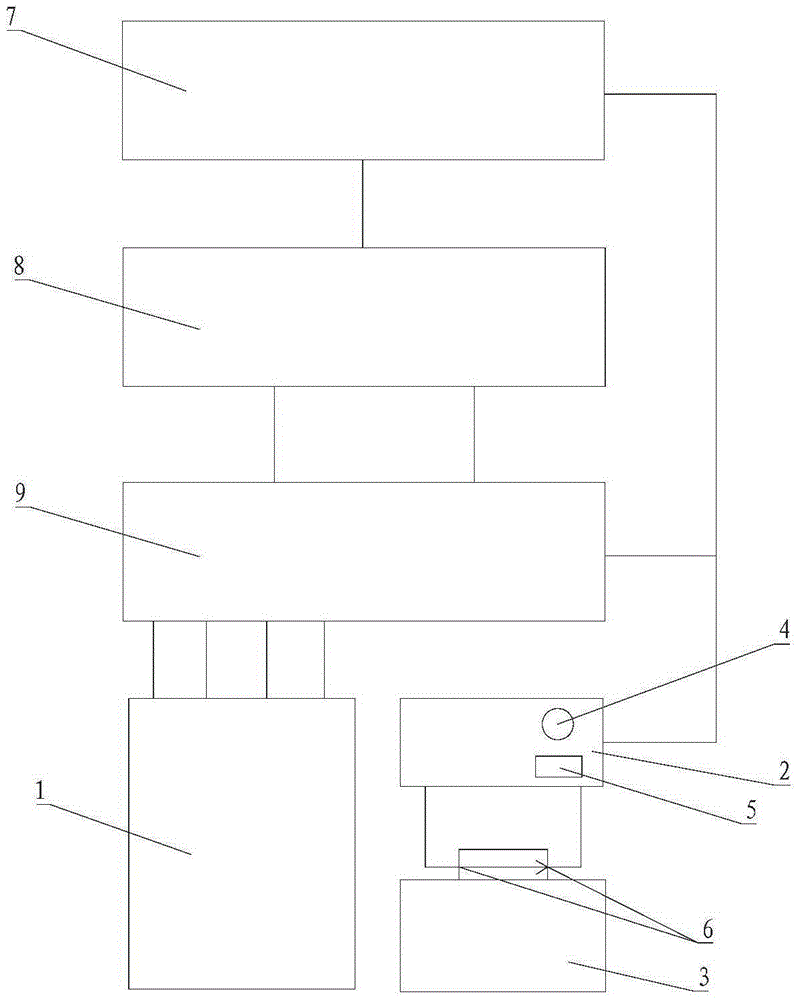

[0031] Please refer to figure 1 , Embodiment 1 of the present invention is: a kind of anti-fool test equipment, including test fixture 1, control box 2, defective product feeding box 3, control equipment 7, network analyzer 8 and switch box 9, described control box 2 Be provided with lamp 4 and buzzer 5, the feed opening of described defective product feeding box 3 is provided with a photoelectric switch 6, and described control box 2 is connected with photoelectric switch 6, and described switch box 9 is connected with described control equipment 7, network. The analyzer 8, the test fixture 1 and the control box 2 are connected.

[0032] The control device 7, such as a computer, is used for installing control software. The control software can control the test process, analyze the test data and judge whether the product is good or bad. The network analyzer 8 is a test instrument, which is connected to the control device 7 and the test fixture 1. The switch box 9 is used to ...

Embodiment 2

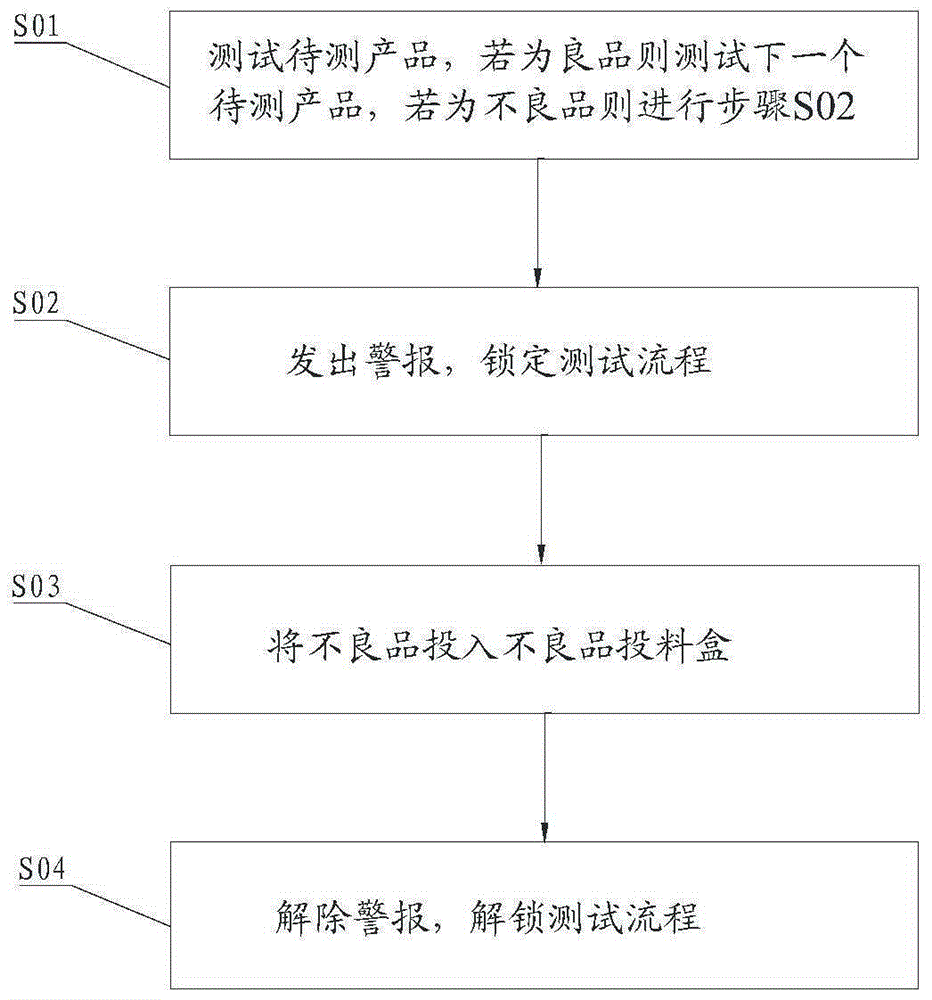

[0034] Please refer to figure 2 , Embodiment 2 of the present invention is: a kind of method that is suitable for the fool-proof test of the fool-proof test equipment of embodiment 1, can be used for qualified detection such as electronic equipment, mechanical parts, and the steps are as follows:

[0035] When starting the test, the control software installed in the control device 7 controls the control box 2 to output an action signal to start the test to the switch box 9, so that the test fixture 1 and the network analyzer 8 start testing, and the control software obtains the information of the product through TCP / IP. Test the data, and judge whether the product is good or bad, if it is a good product, then carry out the test of the next product to be tested, if it is a defective product, then notify the control box 2, make the light 4 in the control box 2 light red, and the buzzer 5 Make a sound, and let the control box 2 output an action signal to stop the test to the swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com