A uhf RFID tag for laundry management and its manufacturing method

A tag and tag antenna technology, applied in the field of UHFRFID tags, can solve the problems of restricting the popularity of applications, unable to prevent tags from being damaged or performance changes, and tag antenna damage and failure, to improve anti-kneading characteristics and ensure read and write security performance, the effect of widening the operating frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

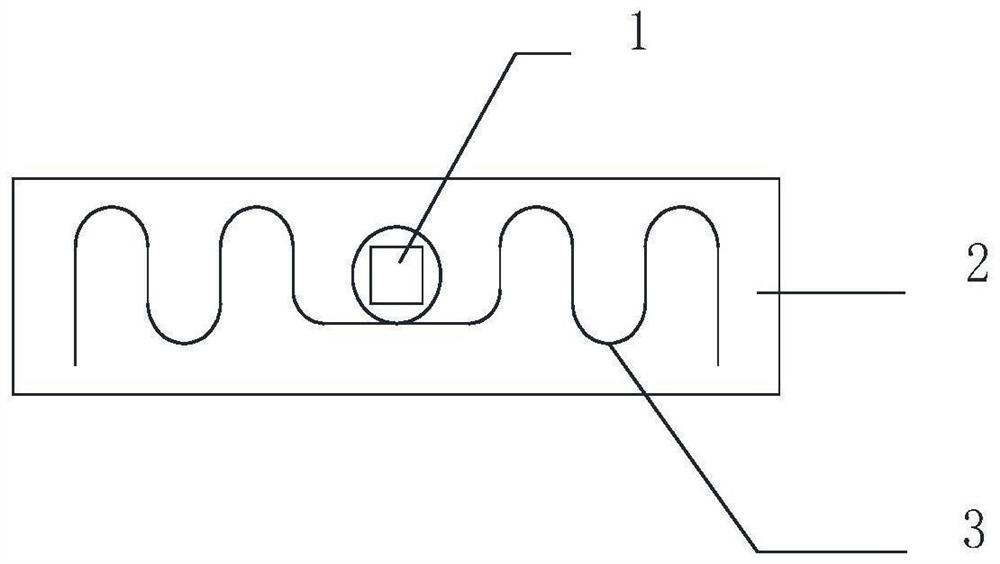

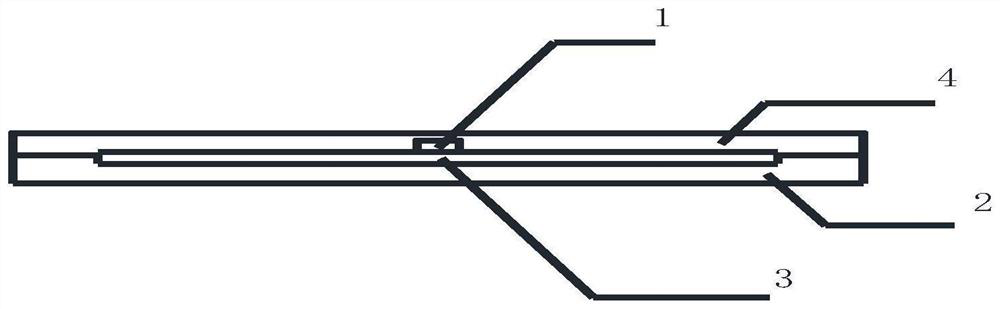

[0033] see figure 1 , figure 2 , a UHF RFID tag for laundry management, including a tag chip 1, a tag antenna 3, a substrate 2 and a cover layer 3 for supporting and packaging the tag chip 1 and the tag antenna 2, and the tag chip 1 is placed on the tag antenna 3 The inductance loop is mutually coupled with the tag antenna 3, and the inductance loop is arranged in the middle of the tag antenna 3, and is a complete loop structure, that is, the current is a complete closed loop current.

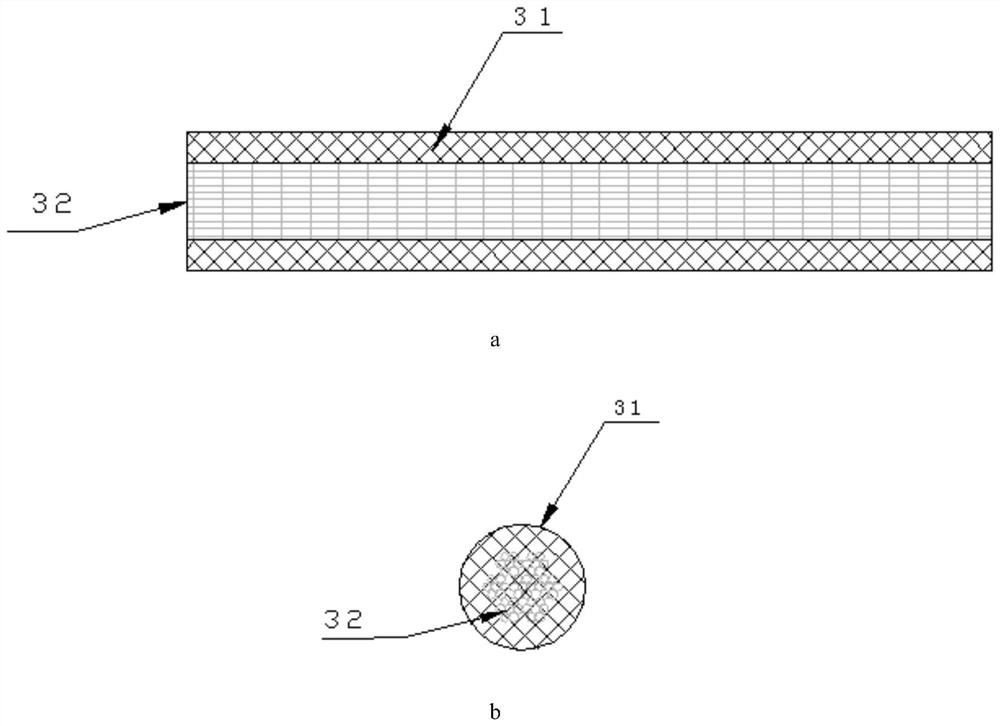

[0034] The tag antenna 2 in this embodiment is a multi-strand conductive fiber twisted wire structure. The tag antenna 2 is formed by stranding a plurality of ultrafine conductive metal fibers, so that it has strong flexibility. The conductive metal fiber is composed of more than 10 strands of thin fibers, its resistivity is lower than 100 ohm / m, and its tensile strength is greater than 10 Newton. The electrical conductivity of the conductive fiber material is not lower than 10,000,000 Siem...

Embodiment 2

[0043] The manufacturing method of the UHF RFID label that is used for laundry management described in embodiment one, its specific steps:

[0044] (1) prepare substrate 2;

[0045] (2) The tag antenna 3 is embedded on the substrate 2 by ultrasonic wire planting equipment, and the middle of the tag antenna 3 is an inductive loop with a complete ring structure;

[0046] (3) Place the label chip 1 in the middle of the inductance loop by using an automatic chip suction machine;

[0047] (4) Covering the substrate with the cover layer 4 to wrap the tag antenna and the tag chip therein.

[0048] In the label making process of this embodiment, ultrasonic automatic wire planting equipment is used to weld the conductive fiber on the base of the chemical fiber fabric according to the design pattern, and an automatic chip suction machine is used to place the integrated package label chip in the middle of the label antenna ring, and then cover it with rubber or fabric And other flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com