An experimental method for testing the expansion retardation performance of polymer microsphere core

A technology for testing experiments and experimental methods, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of serious retention effects, etc., and achieve the effect of simple experimental operation and reliable experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

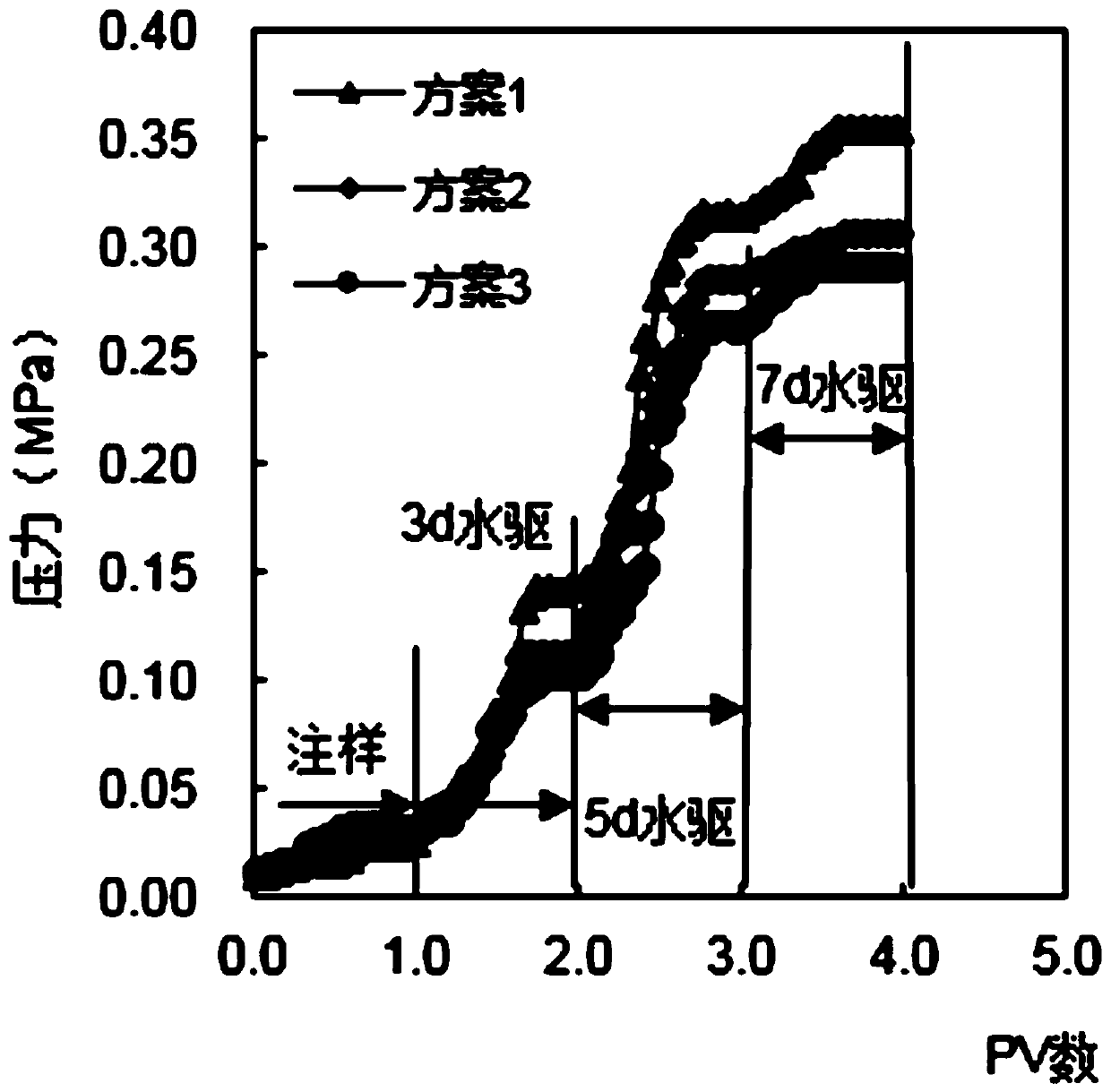

[0033] 1. Experimental conditions

[0034] 1. Medicine and oil and water

[0035] The experimental reagents include 3 kinds of micron-sized polymer microspheres (including polymer microspheres provided by Bohai Oilfield, with an effective content of 100%, code-named "B"; CNOOC Research Institute's polymer microspheres, with an effective content of 100%, code-named "B") Y" and laboratory-made polymer microspheres, with an effective content of 100%, code-named "D").

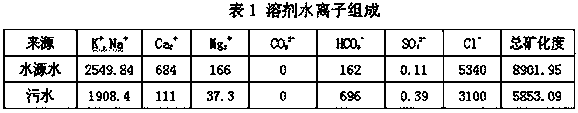

[0036] The experimental water is simulated injection water in LD10-1 oilfield, and its ion composition is shown in Table 1. Use source water to prepare mother liquor, and dilute to the target concentration with mixed water (mixed water is source water: sewage = 1:1).

[0037] 2. Core

[0038] The experimental core is a quartz sand epoxy resin cemented artificial homogeneous core, the appearance geometric size: width × height × length = 4.5cm × 4.5cm × 60cm, the gas permeability is .

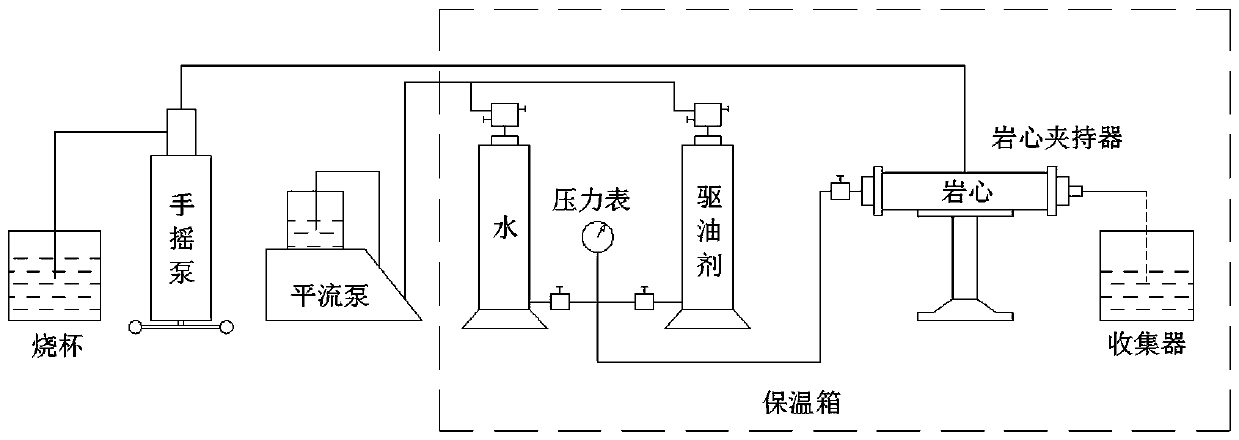

[0039] 3. Instruments an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com