Ultraviolet sterilization device

A sterilizing device and ultraviolet technology, which is applied to measuring devices, photometry, instruments, etc., can solve the problems of short life and rising operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The above-mentioned actions and advantages of the present invention will be clarified from the modes for carrying out the invention described below. Hereinafter, embodiments of the present invention will be described with reference to the drawings. However, the present invention is not limited to these forms. In addition, in the drawings, some reference numerals may be omitted.

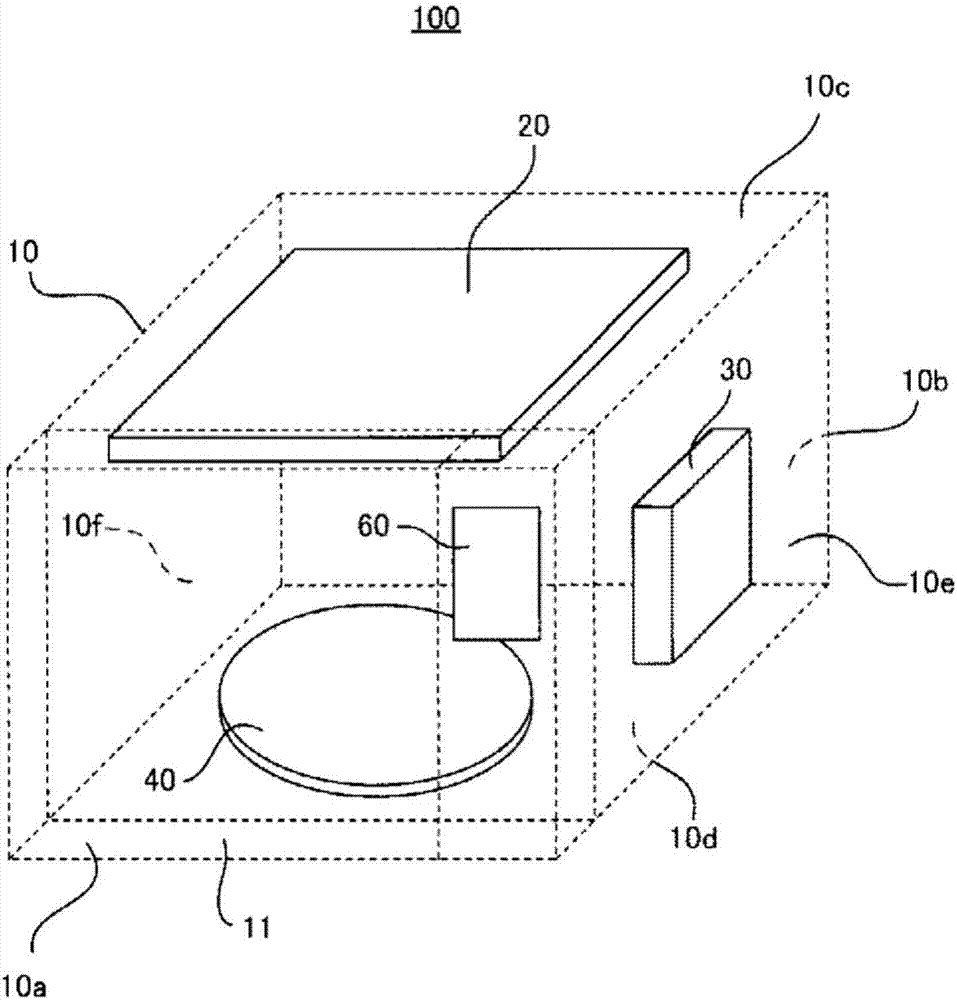

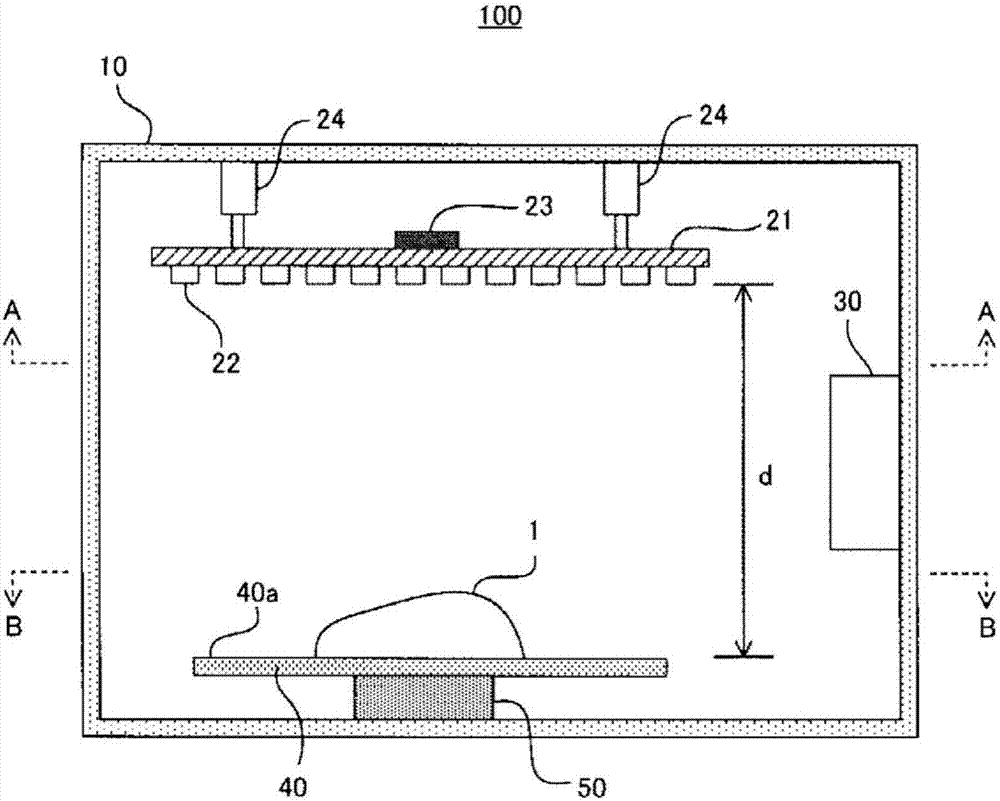

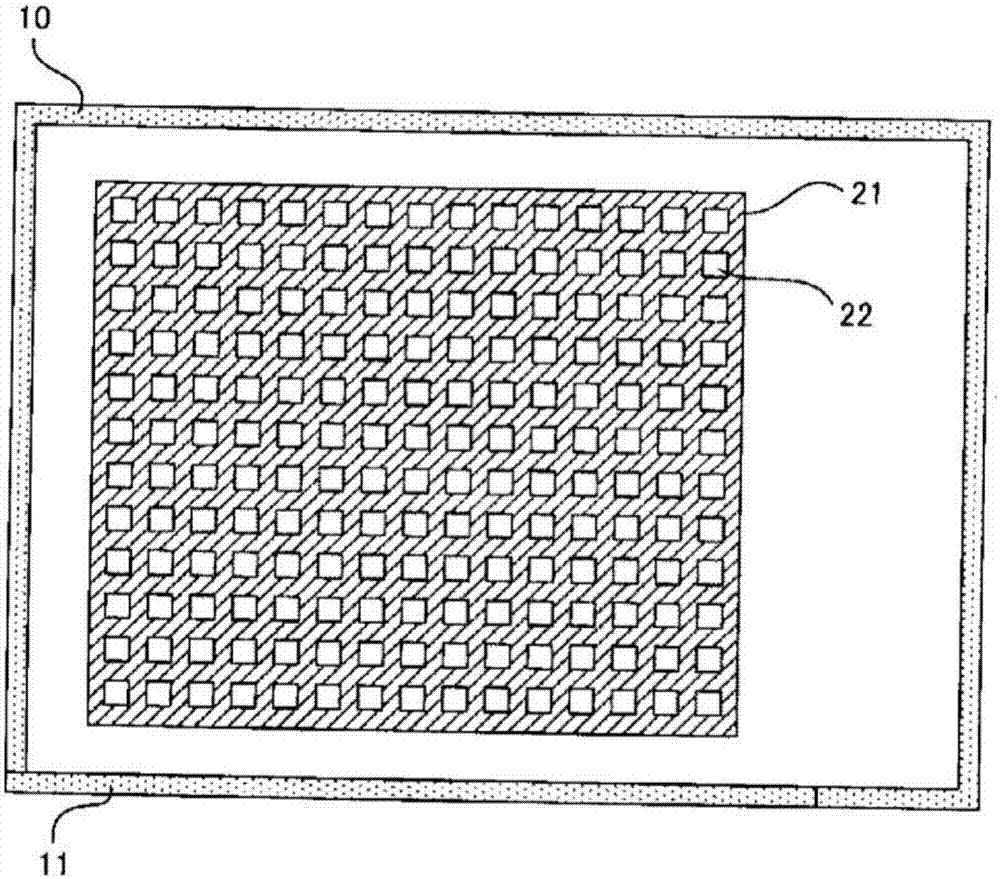

[0048] figure 1 It is a schematic perspective view schematically explaining the ultraviolet disinfection device 100 which concerns on one Embodiment of this invention, and is a figure which sees through the casing 10 (described later). figure 2 It is a cross-sectional view of the ultraviolet disinfection device 100 viewed from the front. The ultraviolet sterilizing device 100 has: a box-shaped housing 10, which has a front surface 10a, a rear surface 10b, an upper surface 10c, a bottom surface 10d, side surfaces 10e and 10f; a deep ultraviolet light source 20, which is arranged on the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com