Austenitic stainless steel sheet, cover member, and method for producing austenitic stainless steel sheet

A stainless steel plate, austenitic technology, applied in the direction of record carrier structural parts, carrier covers, manufacturing tools, etc., can solve the problems of easy adhesion of dust, reduced cleaning performance, etc., to improve hydrophilicity, improve cleaning performance and improve cleaning performance. Anti-glare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

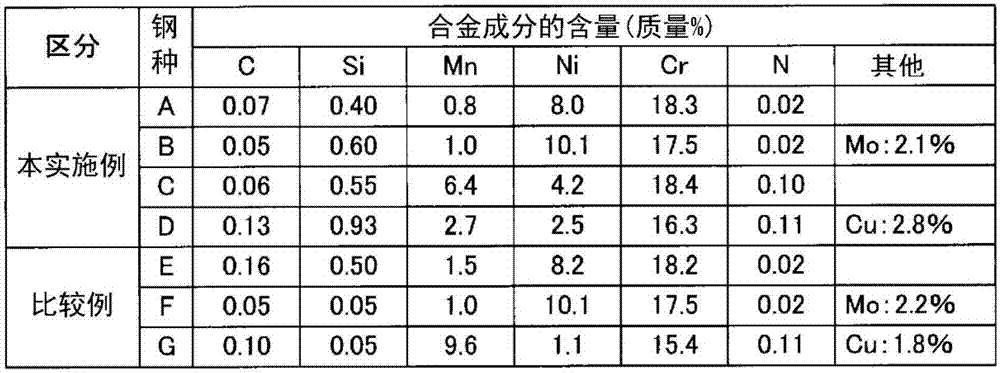

[0130] First, stainless steel with the chemical composition shown in Table 1 was smelted and continuously cast using an electric furnace, a converter, and a VOD process to obtain a slab.

[0131] [Table 1]

[0132]

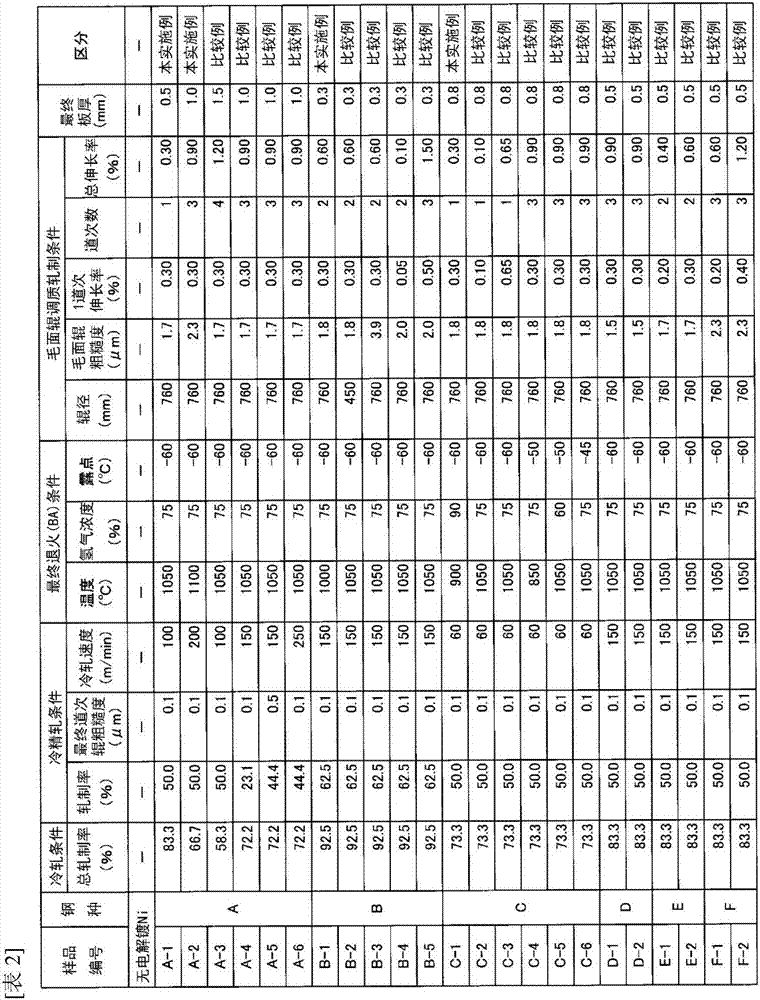

[0133] Next, the continuously cast slab is hot-rolled by a usual method to obtain a hot-rolled steel sheet. And, using the hot-rolled steel sheet as the starting material, each process is carried out in the order of the above-mentioned process (ii) or process (iii), and at the same time, a rough-faced roll is used in the tempering process to form a flat material with a plate thickness of 0.3 mm to 1.5 mm. , as the test material of each embodiment and each comparative example. Table 2 lists the production conditions of these present examples and comparative examples.

[0134] In addition, in Table 2, steel type B and steel type E performed each process by process (ii), and other steel types performed each process by process (iii). In addition, in the finish c...

Embodiment 2

[0158] A gasket was injection-molded on the surface of some of the samples produced in Example 1, and the adhesive adhesion between the stainless steel and the gasket was evaluated.

[0159] When performing injection molding of the gasket, first, the modified olefin-based resin adhesive is pre-coated on the surface of the sample.

[0160] In addition, using a styrene-based thermoplastic elastomer compound, the gasket was injection-molded with an injection molding machine at an injection speed of 0.3 mm / s, an injection pressure of 30 MPa, and a cycle of 30 seconds to adhere to the surface of the sample.

[0161] And, the adhesiveness test was performed as follows.

[0162] In the adhesive test, a penetration peeling of about 1 mm is formed on the pad bonding surface formed on the sample, and a SUS metal wire is passed through the portion where the penetration peeling is formed, and a vertical tensile load is applied to measure the extension of the peeling length. to a load of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Arithmetic mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com