Method for optimizing component type arrangement and device for optimizing component type arrangement

An optimization method and optimization technology, applied in the direction of electrical components, electrical components, configuration CAD, etc., to achieve the effects of shortening the work time for production change and adjustment, improving production efficiency, and minimizing assembly cycle time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

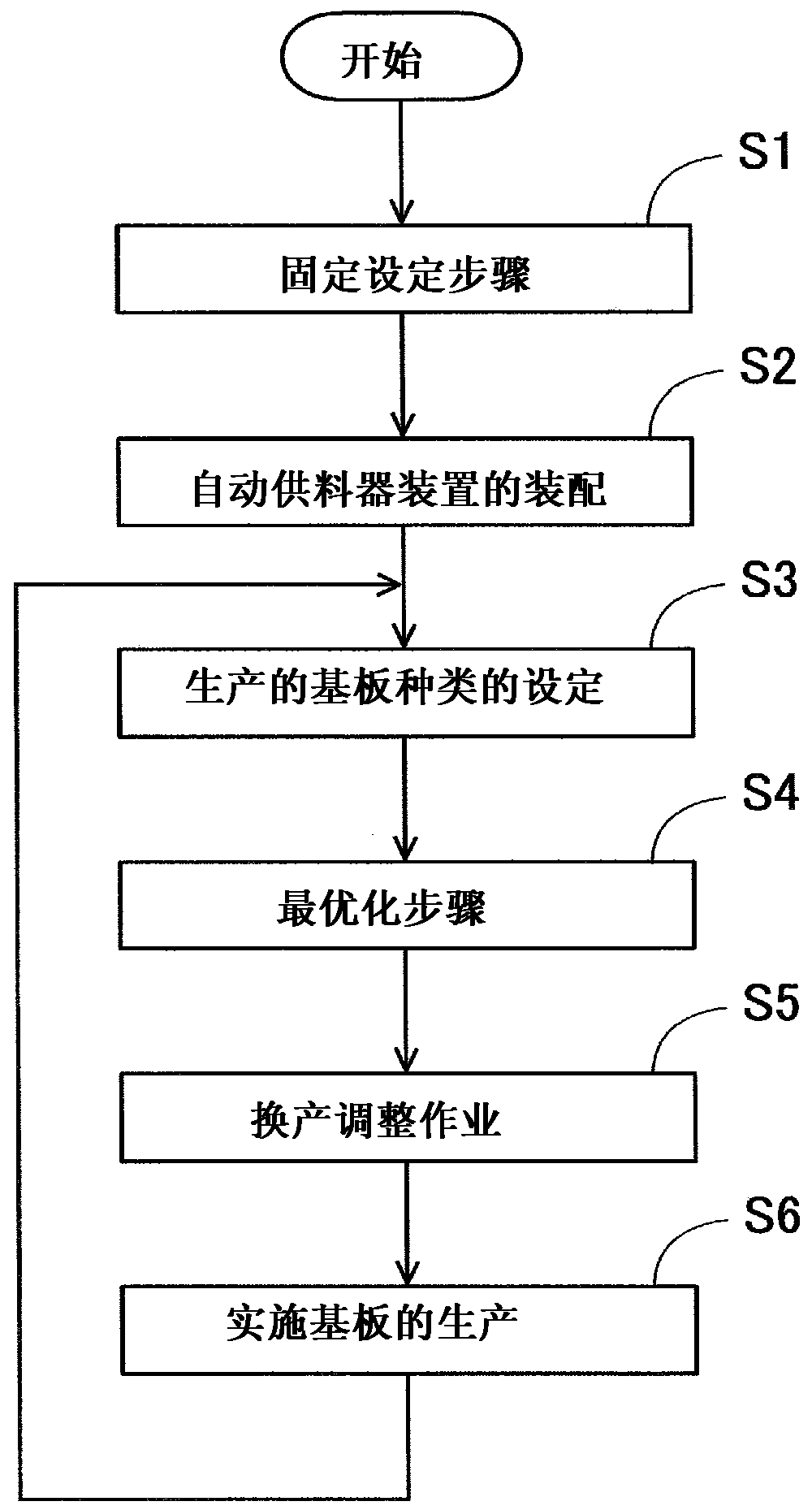

Method used

Image

Examples

Embodiment Construction

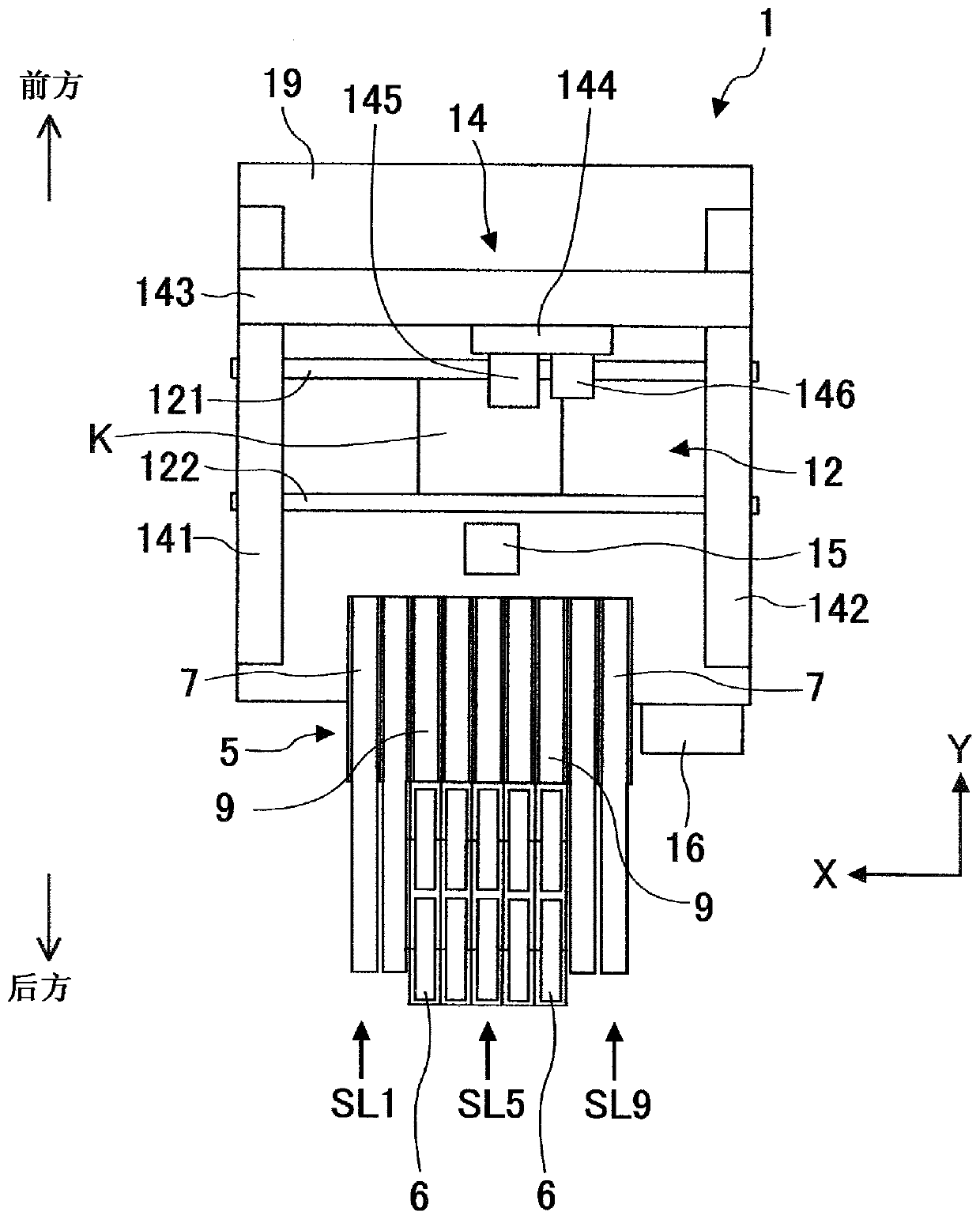

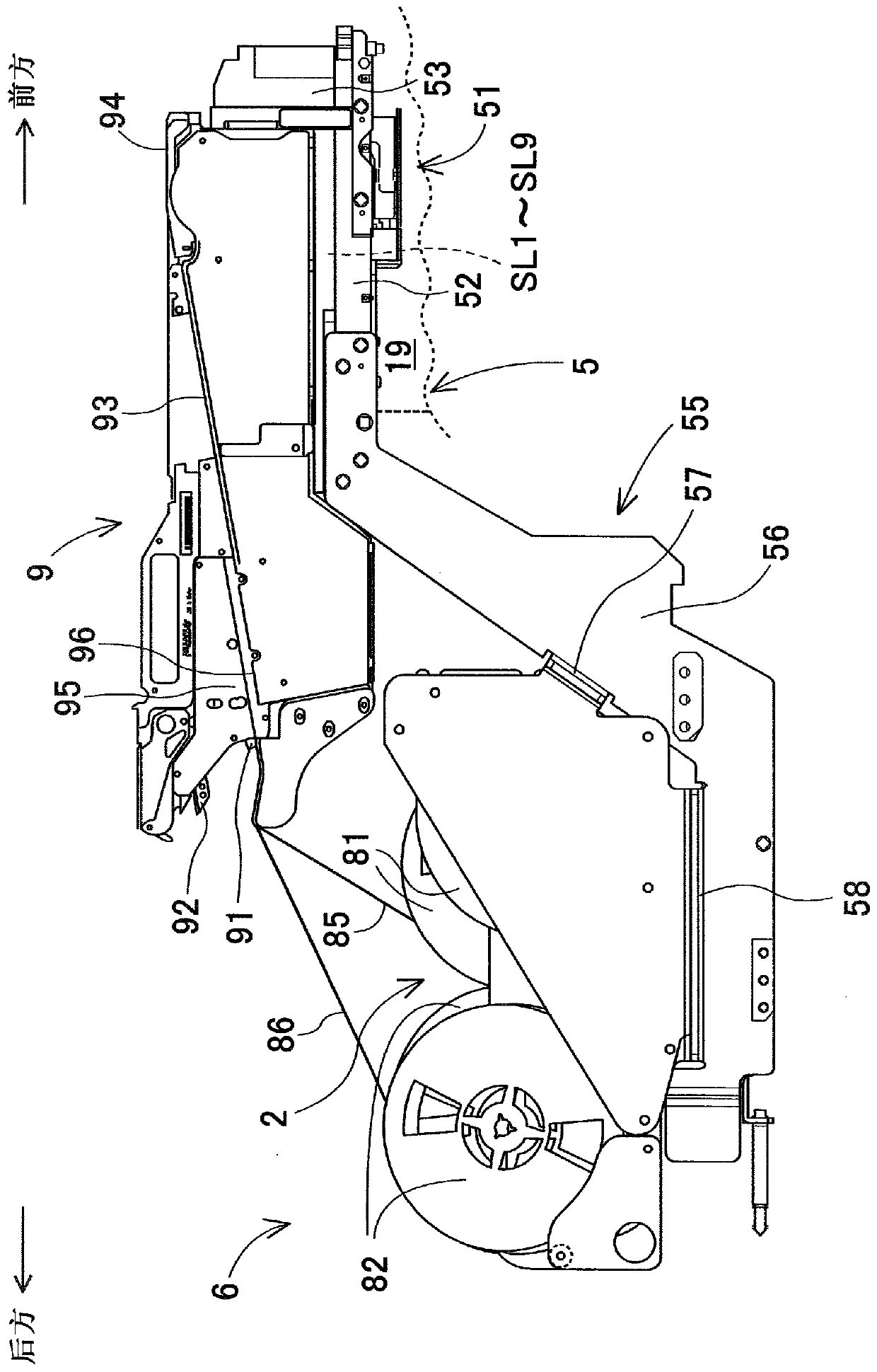

[0025] (1. Overall structure of the component mounting machine 1)

[0026] First, with figure 1 The overall structure of the component mounting machine 1 for performing the optimization method of component type arrangement according to the first and second embodiments of the present invention will be described for reference. figure 1 It is a top view schematically showing the overall structure of the component mounting machine 1 in a simplified manner. figure 1 The direction from the right side to the left side of the drawing is the X-axis direction of loading and unloading the substrate K, and the direction from the rear of the lower side of the drawing to the front of the upper side of the drawing is the Y-axis direction. The component mounting machine 1 is constituted by assembling a substrate transfer device 12 , a detachable manual feeder device 7 and an automatic feeder device 9 , a component transfer device 14 , a component camera 15 , and a control device 16 , etc., i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com