Nano-hybrid drug carrier prepared through Pickering emulsion template method with magadiite serving as emulsifier and preparation method of nano-hybrid drug carrier

A technology of magadiite and emulsion template method, which is applied in the direction of drug delivery, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., and can solve problems such as damage to emulsion application, application restrictions, and human injury , to achieve the effect of reducing phagocytosis, easy operation and improving loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

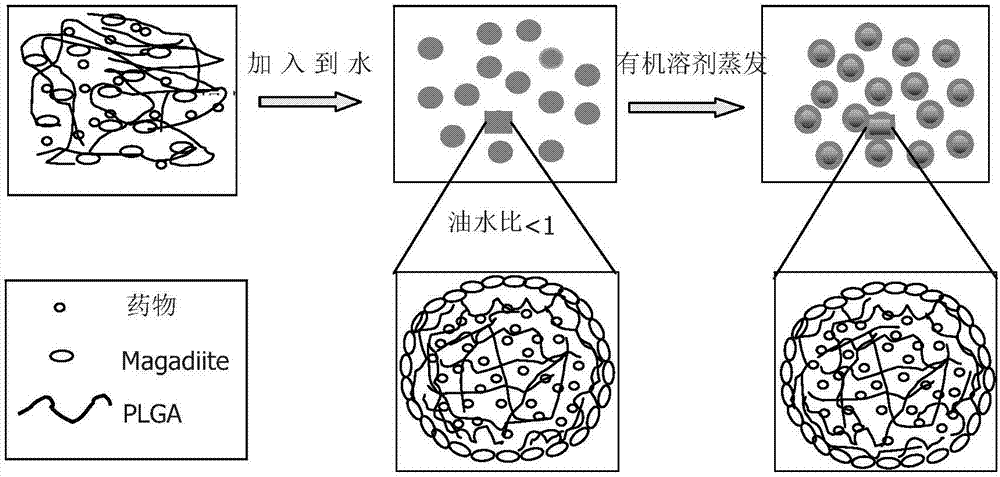

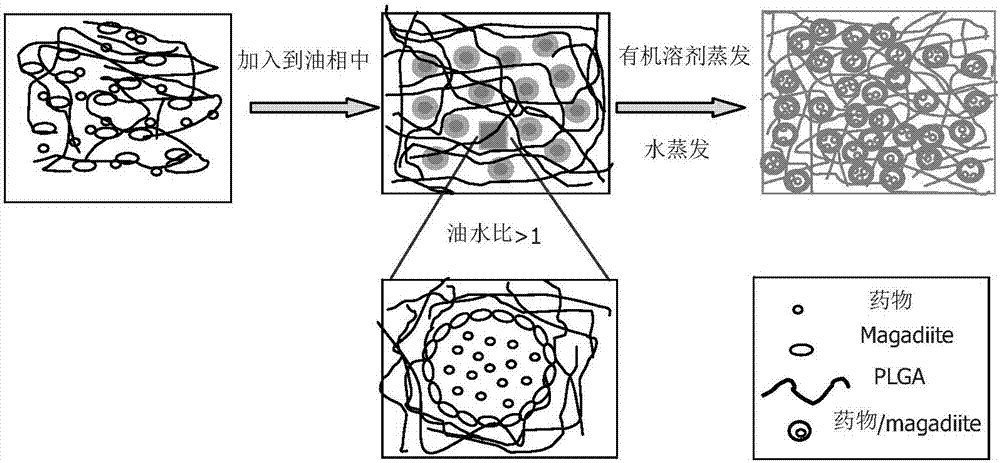

Method used

Image

Examples

Embodiment 1

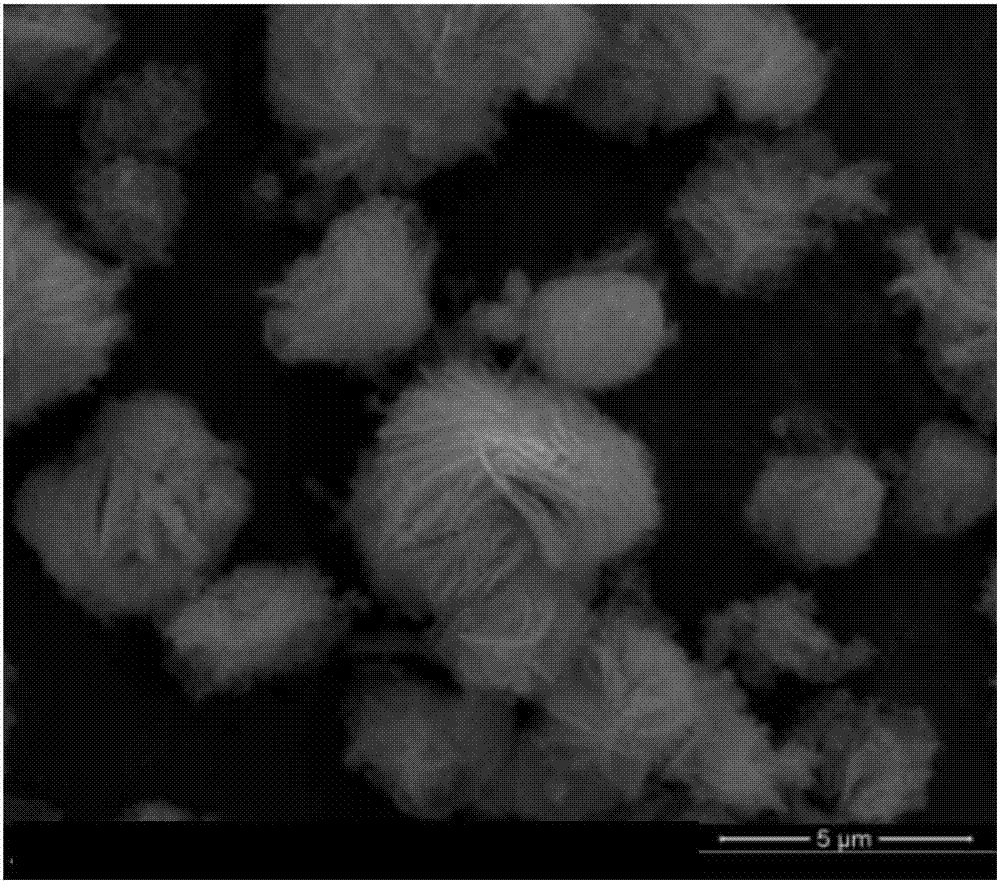

[0041] Weigh 5g magadiite (see SEM image Figure 3a ) and 1g of hexadecyltriphenylphosphonium bromide were put into a 500ml beaker, and 100ml of deionized water was added, and the beaker was placed in a magnetic stirring water bath and stirred at 80°C for 24 hours. After the reaction was completed, The product was filtered and washed 3 times with deionized water, and the resulting filtrate was dried at 80°C for 6h, and then ground to obtain organic magadiite (see SEM image in Figure 3b ). Weigh 2mg of levonorgestrel, 1g of organic magadiite and 1g of PLGA, mix and dissolve in 50ml of ethyl acetate, put them in a 100ml beaker after mixing, put them in a magnetic stirring water bath and stir at room temperature for 6h After that, put it in an ultrasonic environment (40KHz) for 3 hours, and then add it to deionized water, with a water-to-oil volume ratio of 1:2. Mix ultrasound to obtain a stable and uniform milky white Pickering emulsion (polarized light microscope picture see...

Embodiment 2

[0043] Weigh 5g of magadiite and 1g of cetyltrimethylammonium bromide into a 500ml beaker, add 100ml of deionized water, place the beaker in a magnetic stirring water bath and stir at 80°C for 24 After the reaction was completed, the product was filtered and washed three times with deionized water, and the obtained filtrate was dried at 80° C. for 6 h, and then ground to obtain organic magadiite. Weigh 1g of organic magadiite and 1g of PLGA, mix and dissolve in 50ml of dichloromethane, put them in a 100ml beaker after ultrasonic mixing, dissolve 2mg of doxorubicin in 50ml of deionized water, separate the oil phase and the water phase Mixed, the volume ratio of water to oil is 2:1, and placed in an ultrasonic environment (40KHz) for 3 hours to obtain a stable milky white Pickering emulsion. Afterwards, the dichloromethane in the oil phase was removed by solvent evaporation, and finally dried under vacuum at 80° C. to obtain a nano-hybrid drug controlled-release membrane contain...

Embodiment 3

[0045] Weigh 5g of magadiite and 1g of hexadecyl trimethyl quaternary phosphonium salt into a 500ml beaker, add 100ml of deionized water, place the beaker in a magnetic stirring water bath and stir at 80°C for 24 hours , after the reaction was completed, the product was filtered and washed three times with deionized water, and the obtained filtrate was dried at 80° C. for 6 h, and then ground to obtain organic magadiite. Weigh 2mg of 5-fluorouracil, 1g of organic magadiite and 1g of PLGA, mix and dissolve in 50ml of ethyl acetate, mix them uniformly by ultrasonic, put them in a 100ml beaker, put them in a magnetic stirring water bath and stir at room temperature for 6h After that, place it in an ultrasonic environment (40KHz) for 3 hours, and then add it to deionized water, with a water-to-oil volume ratio of 8:9. Stable and uniform milky white Pickering emulsion was obtained by mixing with ultrasound, and the ethyl acetate in the oil phase was removed by solvent evaporation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com