Embossing method for tissue paper making

A technology of embossing and paper web, which is applied in the embossing field of papermaking, which can solve the problems of multiple processing procedures and lower production efficiency, and achieve the effects of reducing processing procedures, improving production efficiency and reducing production costs

Active Publication Date: 2017-12-01

高唐融知融智科技服务有限公司

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The present invention intends to provide an embossing method for papermaking, which can solve the problems of increasing the processing flow and reducing the production efficiency caused by the need to emboss the paper separately in the existing household paper manufacturing device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0049] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

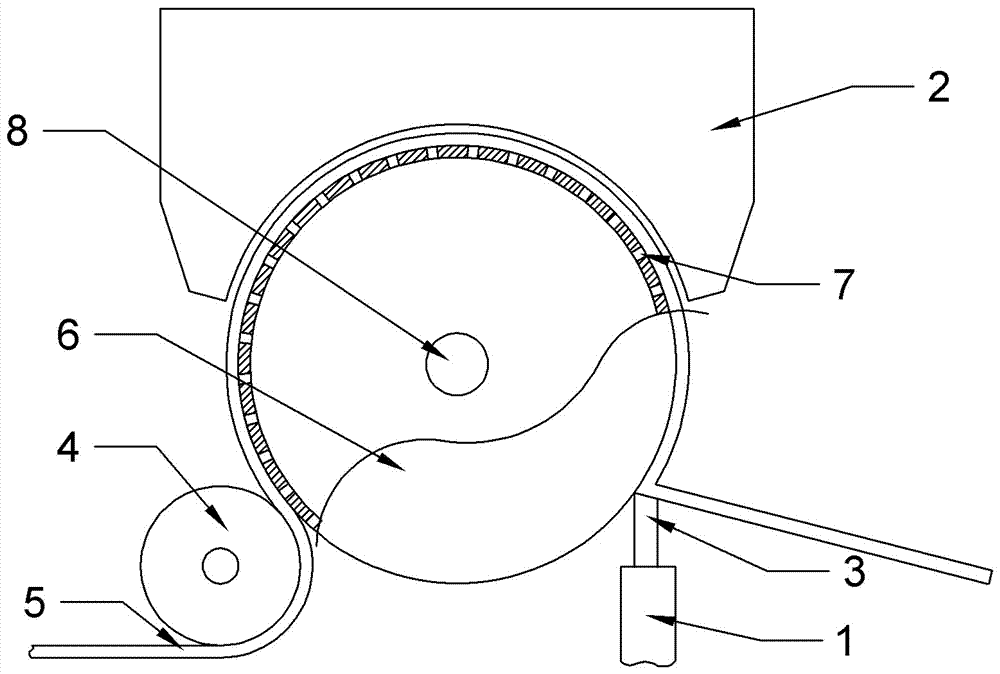

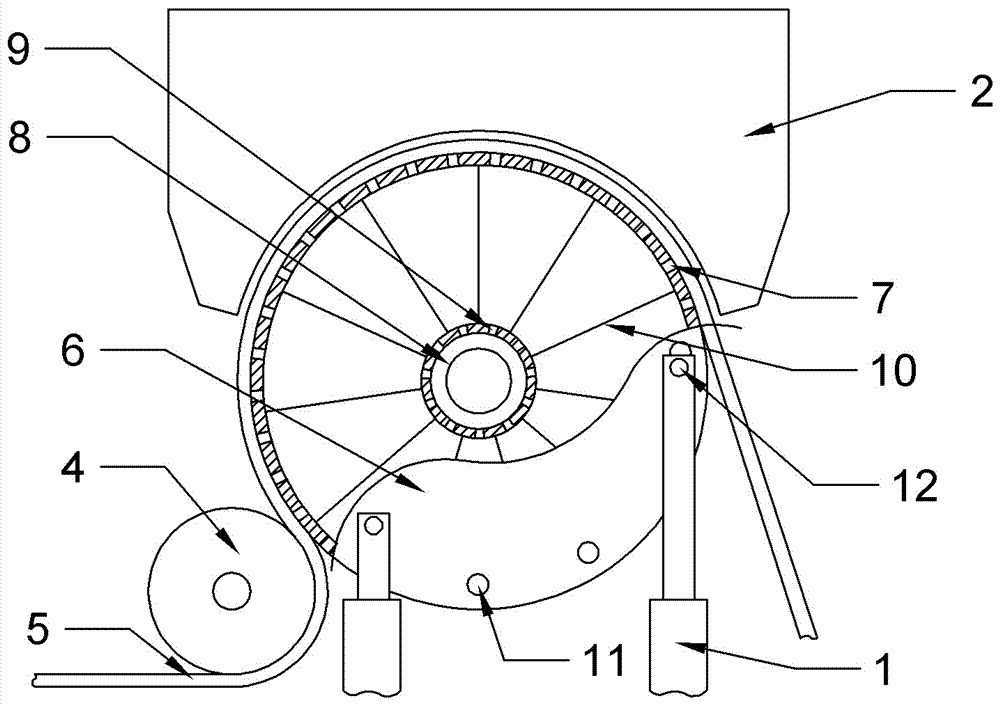

The invention relates to the technical field of tissue paper making, and concretely relates to an embossing method for tissue paper making. The method comprises the following steps of receiving a tissue paper web, wherein a transfer roll receives the upstream formed tissue paper web and sends the tissue paper web onto the surface of a drying cylinder; setting a pattern, wherein a controller controls corresponding first controllable air holes to open according to the preset pattern; adsorbing for embossing, wherein a suction ventilator inwards suck air through the first controllable air holes, adsorbs the tissue paper web on the surface of the drying cylinder, and downwards sucks the tissue paper web at the corresponding parts of the first controllable air holes so as to form a concave-convex floral pattern; drying for forming, wherein the drying cylinder heats the tissue paper roll to dry the tissue paper roll and finalize the pattern; and outputting the tissue paper roll, wherein the downstream transfer roll transfers the tissue paper web onto a downstream device. The embossing method for tissue paper making provided by the invention can solve the problems that the processing flows are multiple and the production efficiency is reduced since tissue paper needs to be separately embossed in an existing household tissue paper manufacturing device.

Description

technical field [0001] The invention relates to the technical field of papermaking, in particular to an embossing method for papermaking. Background technique [0002] Household paper is widely used in daily life, such as facial tissue, toilet paper, wiping paper, etc. are well known to the public. In the manufacturing process of tissue paper, in order to improve certain physical properties of tissue paper, such as bulkiness, water absorption, etc., and to increase the aesthetics of tissue paper, after the production of tissue paper is completed, it will be processed in the post-processing section Emboss the paper. [0003] The embossing process in the processing section usually makes the paper pass through the embossing nip formed by two rollers to achieve the purpose of forming patterns on the surface of the paper, one or two of which are provided with raised or depressed embossed patterns on the surface. [0004] Although the existing embossing process can form the requ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B31F1/07

CPCB31F1/07

Inventor 李泽世张善芳彭绅彭铂祯

Owner 高唐融知融智科技服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com