A kind of production method of double-sided composite fleece and obtained double-sided composite fleece

A technology of composite flannelette and production method, which is applied in the field of double-sided composite flannelette, and can solve problems such as the separation of composite flannelette, the inability to tighten it with a large force, and affecting the service life of the flannelette.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

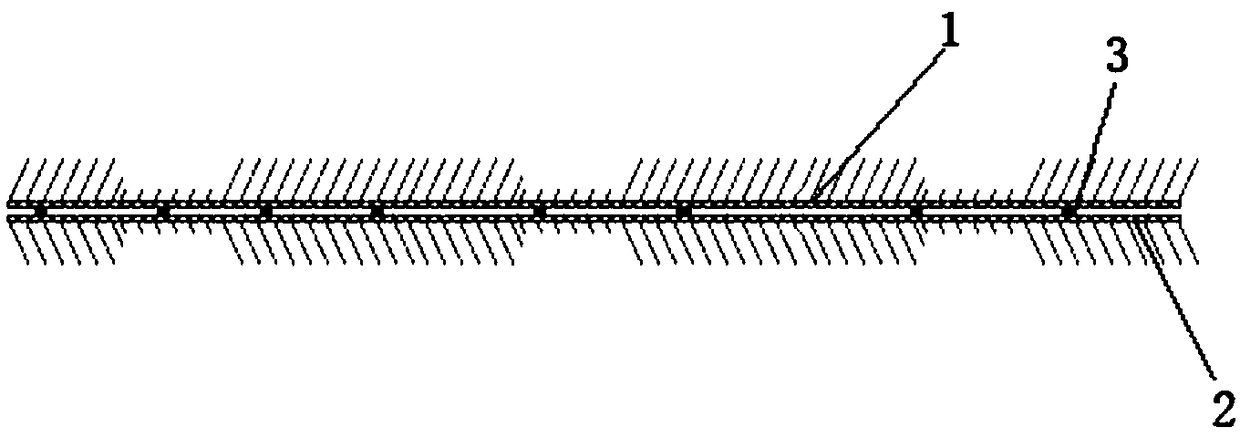

[0026] This embodiment provides a kind of double-sided composite flannelette of baby fleece and flannel, comprising:

[0027] S1: Weaving, use 100% polyester to weave two sheets of single-face fleece, such as baby fleece 1 and flannel 2;

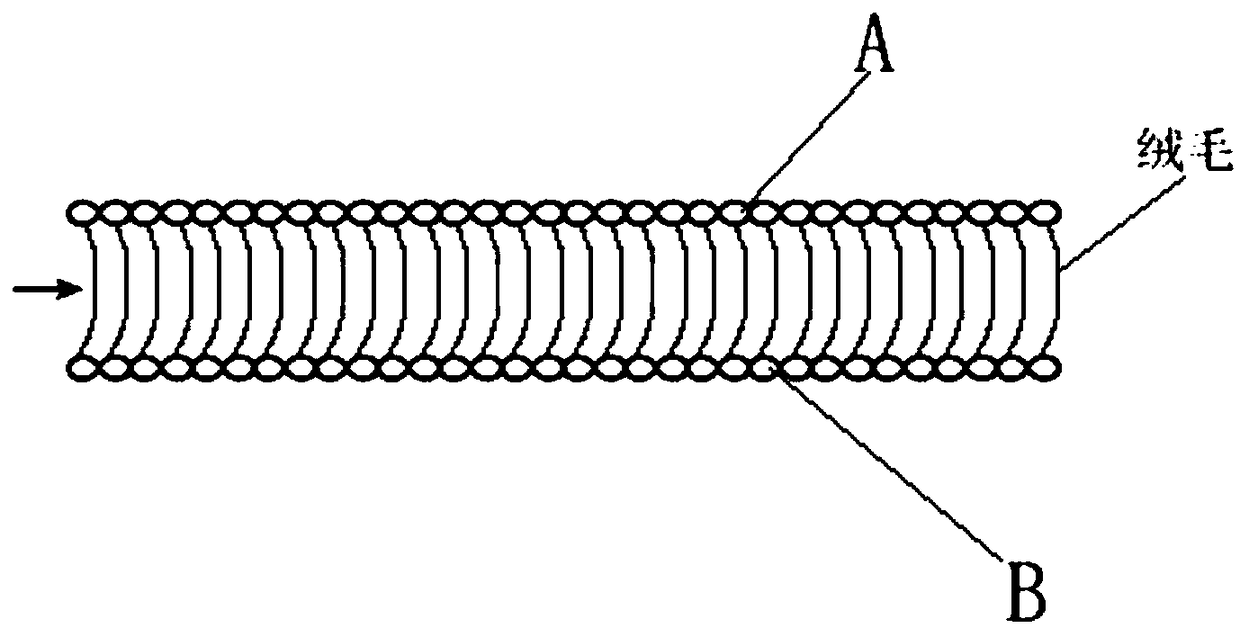

[0028] When weaving, the baby cashmere 1 and the flannel 2 can be woven into gray cloth (obtainable by using a warp knitting machine), and the structure of the gray cloth is as follows: figure 1 As shown, it includes side A, side B and the wool connecting side A and side B, and then cut from the middle to obtain two pieces of baby fleece 1 and flannel 2 with single-sided fleece. Cutting in the middle to obtain flannelette can reduce the material waste of

[0029] After weaving, the burnt-out operation can also be performed on the fluff of the single-face fleece separately to form a burnt-out pattern;

[0030] S2: Use white latex to adhere the bottom surface of two pieces of single-face fleece. The white latex forms a network structure form...

Embodiment 2

[0035] This embodiment provides a kind of double-sided composite flannelette of baby fleece and flannel, comprising:

[0036] S1: Weaving, use 100% polyester to weave two sheets of single-face fleece, such as baby fleece 1 and flannel 2;

[0037] When weaving, the baby cashmere 1 and the flannel 2 can be woven into gray cloth (obtainable by using a warp knitting machine), and the structure of the gray cloth is as follows: figure 1 As shown, it includes side A, side B and the wool connecting side A and side B, and then cut from the middle to obtain two pieces of baby fleece 1 and flannel 2 with single-sided fleece. Cutting in the middle to obtain flannelette can reduce the material waste of

[0038] After weaving, the burnt-out operation can also be performed on the fluff of the single-face fleece separately to form a burnt-out pattern;

[0039] S2: Use white latex to adhere the bottom surface of two pieces of single-face fleece. After the white latex is dried (usually by tum...

Embodiment 3

[0044] This embodiment provides a kind of double-sided composite flannelette of baby fleece and flannel, comprising:

[0045] S1: Weaving, use 100% polyester to weave two sheets of single-face fleece, such as baby fleece 1 and flannel 2;

[0046] When weaving, the baby cashmere 1 and the flannel 2 can be woven into gray cloth (obtainable by using a warp knitting machine), and the structure of the gray cloth is as follows: figure 1 As shown, it includes side A, side B and the wool connecting side A and side B, and then cut from the middle to obtain two pieces of baby fleece 1 and flannel 2 with single-sided fleece. Cutting in the middle to obtain flannelette can reduce the material waste of

[0047] After weaving, the embossing operation can be performed on the single-face cashmere separately;

[0048] S2: Use white latex to adhere the bottom surface of two pieces of single-face fleece. After the white latex is dried (usually by tumble drying), the white latex forms a network...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com