Transparent easily-torn sealing film and manufacturing method thereof

A manufacturing method and technology of easy-to-tear lids, which are applied in the field of flexible packaging, can solve problems such as not easy to open, unsafe, inconvenient and troublesome for consumers, and achieve the elimination of aluminum foil that is easy to scratch fingers, eliminate potential safety hazards, and be easy to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (Example 1, transparent easy-tear cover sealing film)

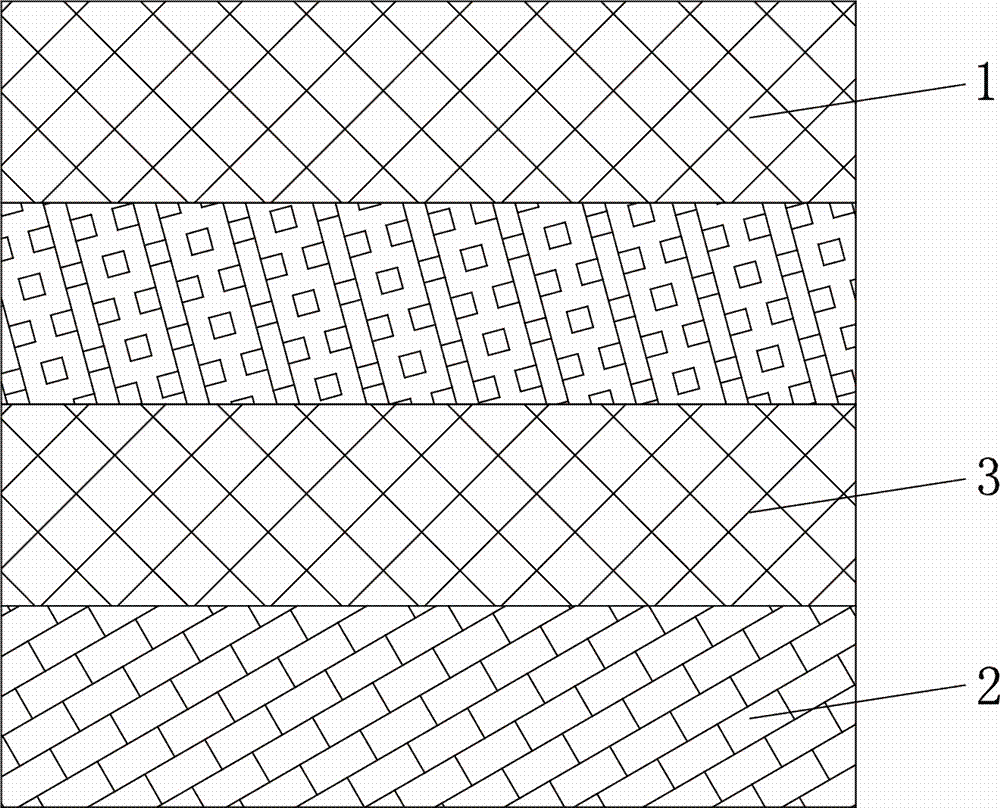

[0031] see figure 1 , a transparent easy-to-tear lid sealing film, including a base, the base includes a printing layer 1, an adhesive layer, a barrier layer 3 and a heat-sealing layer 2 connected in sequence, the thickness of the adhesive layer is 1-5 um, and the printing layer is A polyethylene terephthalate film layer, the barrier layer is a polyethylene terephthalate film layer, and the thickness of the two polyethylene terephthalate film layers is 20-120um, The heat-sealing layer is a heat-sealing adhesive layer, and the thickness of the heat-sealing adhesive layer is 2-10 um.

Embodiment 2

[0032] (Example 2, transparent easy-tear lid sealing film)

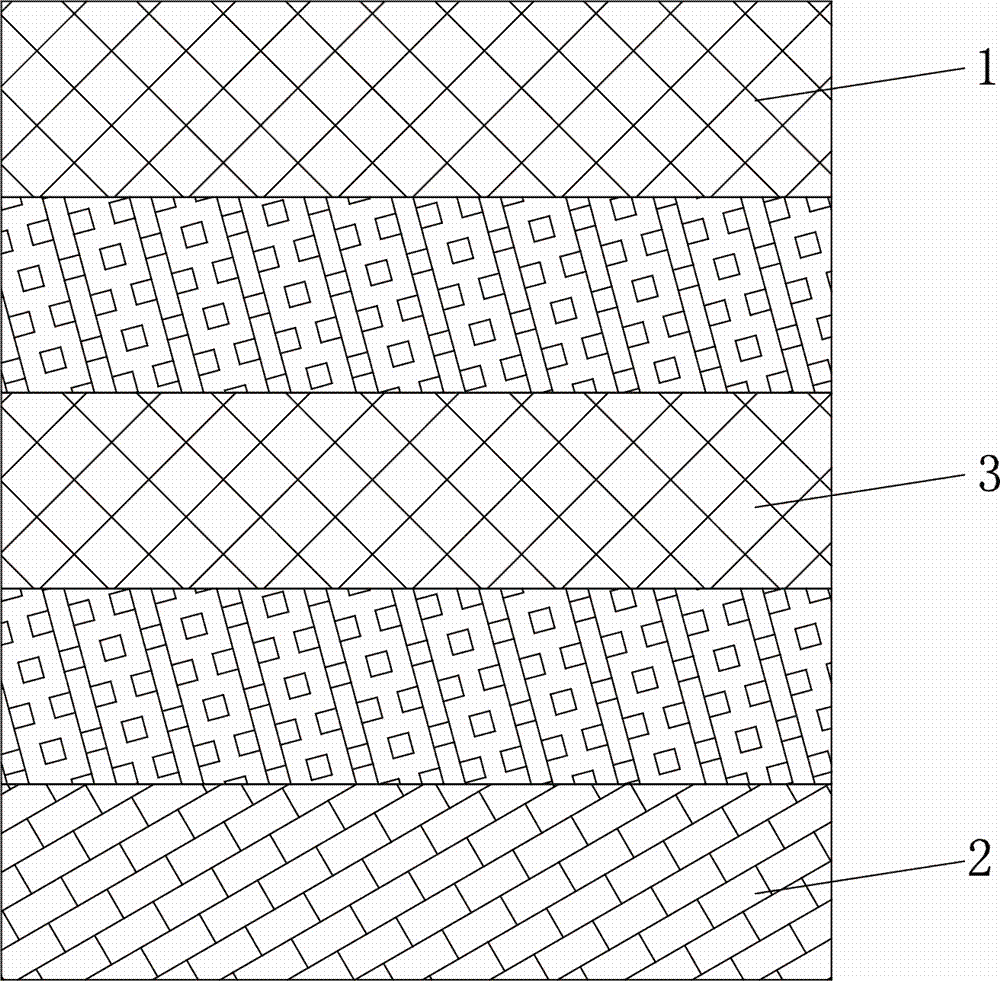

[0033] see figure 2 , a transparent and easy-to-tear lid sealing film, including a substrate, the substrate includes a printing layer 1, an adhesive layer, a barrier layer 3, an adhesive layer, and a heat-sealing layer 2 connected in sequence, and the thickness of the adhesive layer is 1-5 um. The printing layer is a polyethylene terephthalate film layer, the barrier layer is a polyethylene terephthalate film layer, and the thickness of the two polyethylene terephthalate film layers is 20-120um, the heat-sealing layer is a cast polypropylene film layer, and the thickness of the cast polypropylene film layer is 20-60 um.

Embodiment 3

[0034] (Example 3, transparent easy-tear cover sealing film)

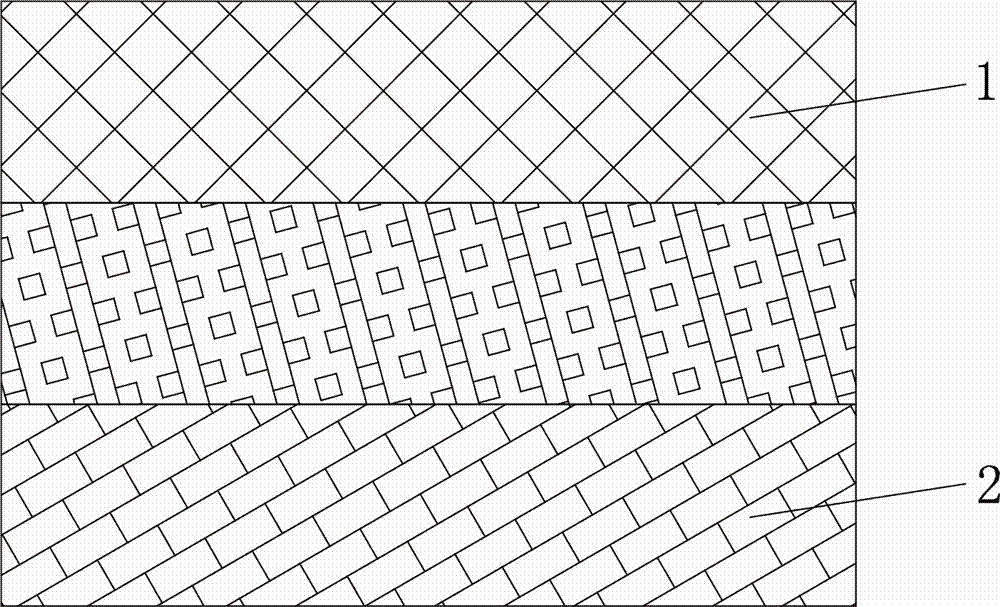

[0035] see image 3 , a transparent easy-to-tear lid sealing film, including a base, the base includes a printing layer 1, an adhesive layer and a heat-sealing layer 2 connected in sequence, the thickness of the adhesive layer is 1-5 um, and the printing layer is polyethylene terephthalate Ethylene glycol formate film layer, the thickness of the polyethylene terephthalate film layer is 20-120um, and the heat-sealing layer is a cast polypropylene film layer, and the thickness of the cast polypropylene film layer is 20-80um um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com