Biomass-based flame-retardant polyurethane soft sponge foam and preparation method thereof

A polyurethane and biomass technology, applied in the field of polyurethane soft sponge foam and its preparation, can solve the problems of unconventional methods of synthesis and use of raw materials, and difficulty in producing qualified products, so as to stabilize product prices and reduce dependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

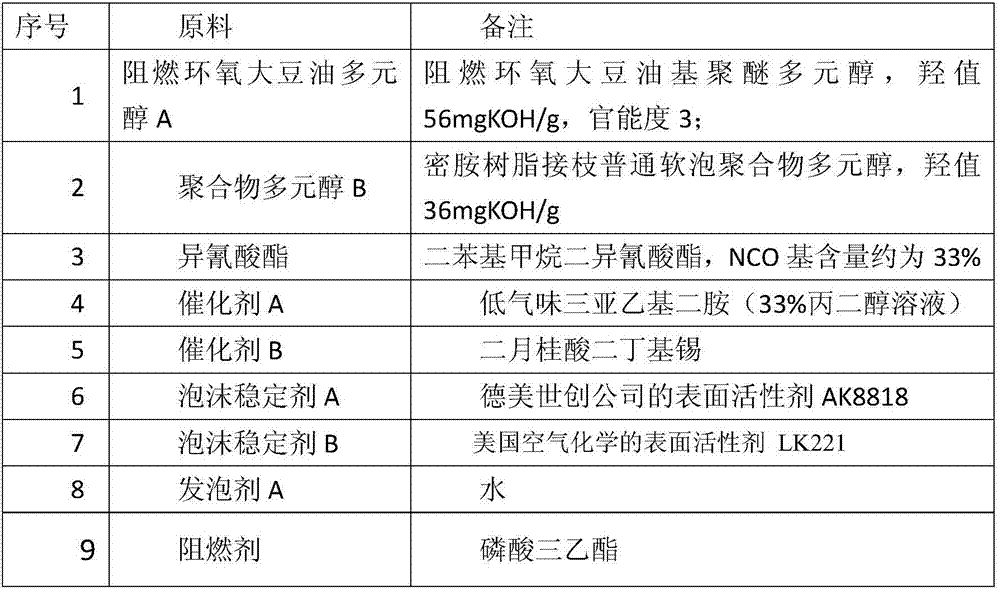

[0023] The present invention is further illustrated by the following examples, but the present invention is not limited to the following examples. Unless otherwise specified, all the amounts given in "parts" and "percentage" should be understood as being by weight. The following materials were used to produce the polyurethane foams of the examples:

[0024] Table 1 Brief Introduction of Polyurethane Raw Materials

[0025]

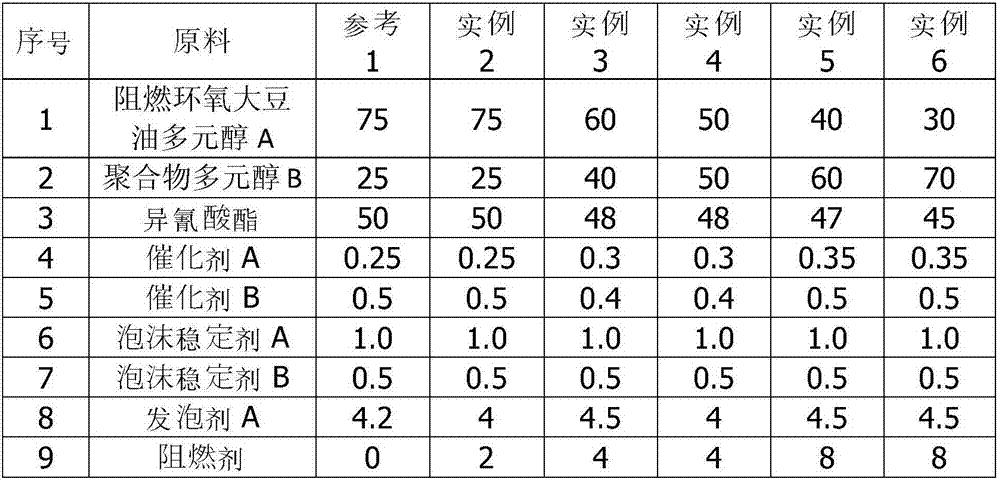

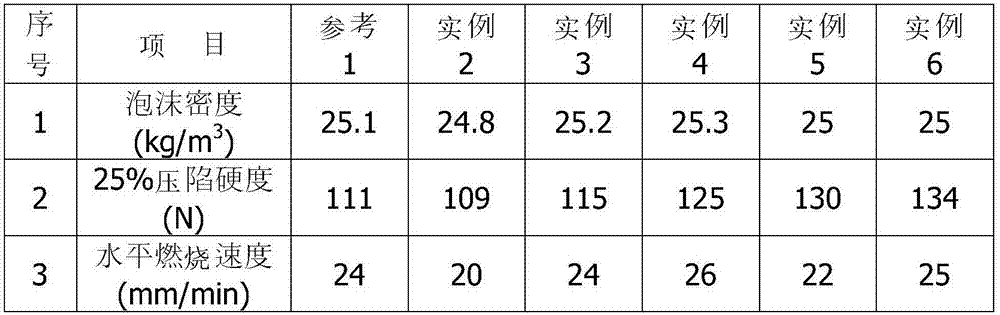

[0026] The preparation method of biomass-based flame-retardant polyurethane soft sponge foam comprises the following steps: (1) flame-retardant epoxy soybean oil polyol A and polymer polyol, catalyst, blowing agent, foam stabilizer, flame retardant and isocyanate components; each component listed in the following table 2 is transported to the foaming machine head by the weight ratio in table 2 through a metering pump, and after high-speed stirring, the cloth is evenly distributed on the kraft paper of the continuous foaming production line to produce A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com