Non-sulfonation high temperature resisting and filtrate loss reduction type water-based drilling fluid

A drilling fluid and high temperature resistance technology, applied in the field of oil drilling, can solve problems such as stuck pipe, blocked seepage channel, well wall instability, etc., and achieves the effect of low cost

Inactive Publication Date: 2017-12-01

SOUTHWEST PETROLEUM UNIV

View PDF11 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

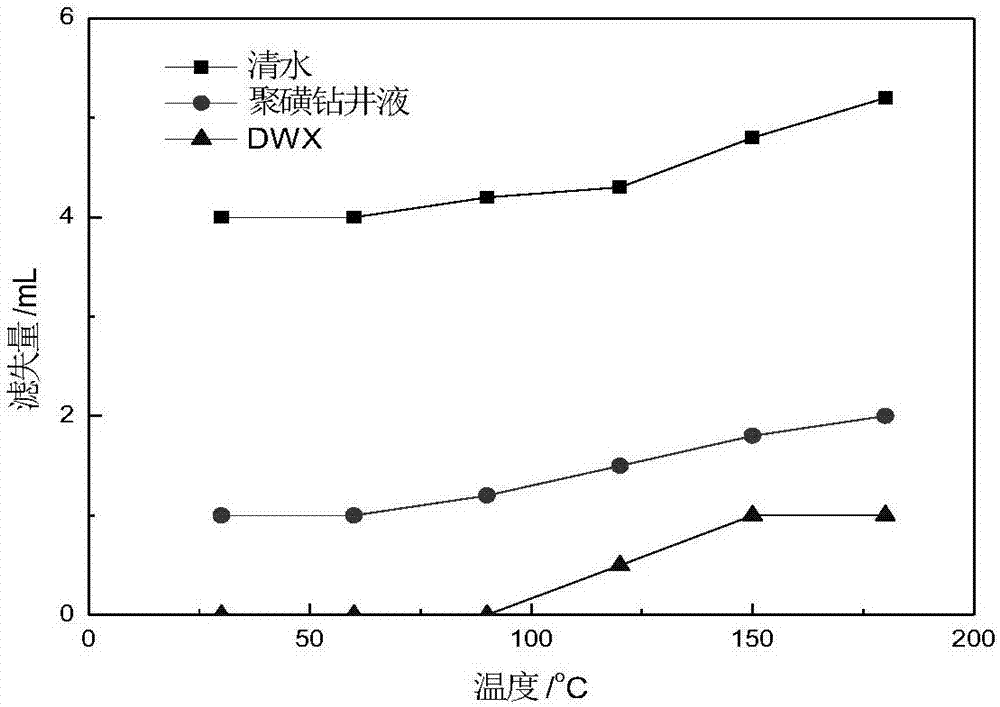

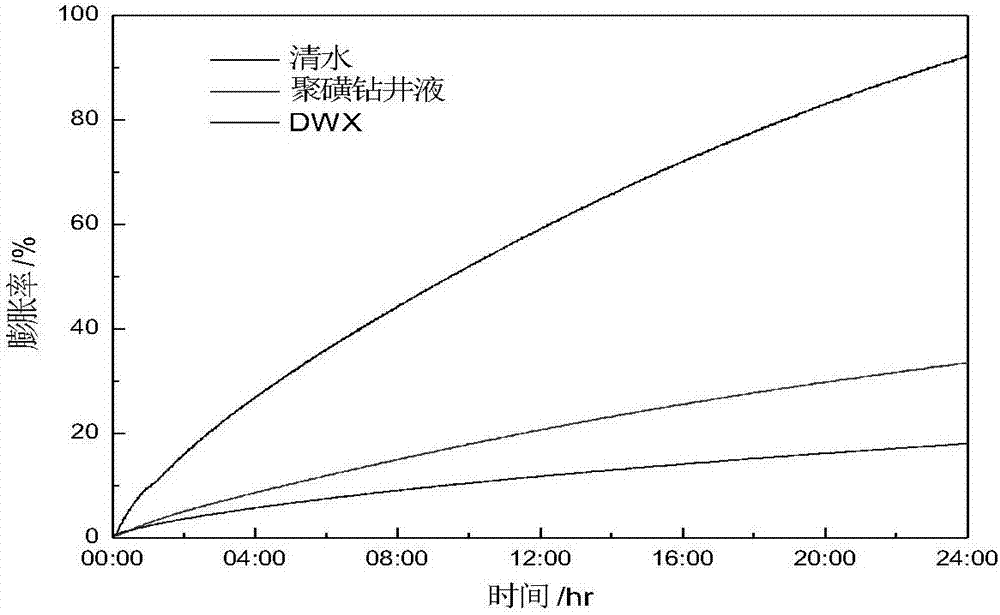

In addition, experimental research and field construction have shown that a substantial increase in temperature and pressure will significantly increase the fluid loss of commonly used drilling fluid systems

A large amount of drilling fluid fluid loss will cause hydration expansion and dispersion of shale, block seepage channels, cause pipe sticking, and in severe cases, easily cause well wall instability

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0022] 1% bentonite, 3% CCM, 2% NMPS, 2% MMC, 5% Na 2 CO 3 , 1% DM and the balance water.

Embodiment 2

[0024] 4% bentonite, 0.25% CCM, 4% NMPS, 0.5% MMC, 3% Na 2 CO 3 , 0.25% DM and the balance water.

Embodiment 3

[0026] 2% bentonite, 1.5% CCM, 3% NMPS, 1% MMC, 4% Na 2 CO 3 , 0.75% DM and the balance water.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to non-sulfonation high temperature resisting and filtrate loss reduction type water-based drilling fluid. A formula of the drilling fluid provided by the invention comprises the following components based on 100 percent of the weight: 1 percent to 4 percent of bentonite, 0.25 percent to 3 percent of CCM (compound liquid of xanthan gum and N,N'-methylene-bisacrylamide), 2 percent to 4 percent to NMPS (carboxy styrene-butadiene latex), 0.5 percent to 2 percent of MMC (cation emulsified asphalt), 3 percent to 5 percent of Na2CO3, 0.25 percent to 1 percent of DM (high temperature resisting and filtrate loss reduction dispersion liquid) and the balance of water. The drilling fluid provided by the invention has high temperature resisting and filtrate loss reduction performance; a researched synthetic material of the high temperature resisting and filtrate loss reduction type water-based drilling fluid is easy to obtain and low in construction cost, so that the synthetic material is suitable for large-scale industrial production and has oilfield application potential. Furthermore, a drilling fluid system responds to the call on environment protection of China, and the whole system abandons a polysulfonate treatment agent.

Description

technical field [0001] The invention relates to the field of petroleum drilling, in particular to a non-sulfonated high-temperature-resistant and fluid-loss-reducing water-based drilling fluid. Background technique [0002] In recent decades of exploration and development, the crude oil in the shallow section has basically been developed, except for a small amount of oil layers that have not been discovered or exploited. At present, my country's main productive reservoirs are mainly located in deep well sections, for example, the Tarim deep well in my country is as deep as 8408m. With the deepening of oil development and drilling, the downhole high temperature and high pressure environment is inevitable. In addition, experimental research and field construction show that a substantial increase in temperature and pressure will significantly increase the fluid loss of commonly used drilling fluid systems. A large amount of drilling fluid fluid loss will cause hydration expan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09K8/24

CPCC09K8/24

Inventor 苏俊霖董汶鑫黄进军蒲晓林

Owner SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com