Preparation method of gradient macroporous conductive composite hydrogel for flexible strain sensor

A composite hydrogel and strain sensor technology, applied in the field of preparation of gradient macroporous conductive composite hydrogel, can solve the problems of affecting the sensitivity of the sensor, blockage of hydrogel pores, volume expansion of polyaniline, etc., to improve sensitivity, prevent Structural damage, the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

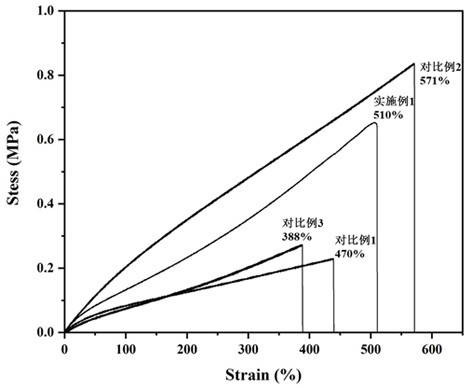

Embodiment 1

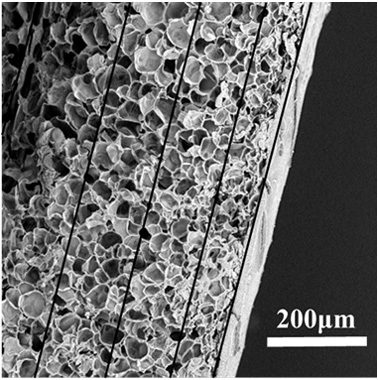

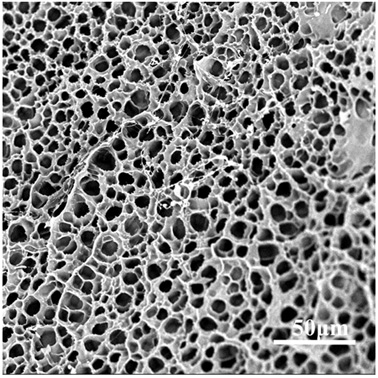

[0032] (1) Dissolve 0.05g sodium chloride and 0.1g sodium dodecyl sulfate in 10ml deionized water, add 54μL dodecyl methacrylate, stir for 3h, add 30mg graphene oxide (GO), and then add 5.3g Acrylamide (AAm), 17.2mg N,N'-methylenebisacrylamide (MBA), 0.02g sodium carbonate, 0.05g ammonium persulfate (APS), fully dissolved by magnetic stirring, polymerized at 45°C for 6h, prepared GPH.

[0033] (2) The prepared GPH was immersed in 80ml 0.2mol / L ascorbic acid solution for 5h, then heated at 90°C for 8h, and then soaked in deionized water for 48h (deionized water was changed every 4h), after cleaning and removing impurities RGPH was prepared.

[0034] (3) The prepared RGPH was placed in 80 ml of 0.1 mol / L aniline hydrochloride solution containing 1.6 mmol of phytic acid, sealed and stored for 12 h, and then cooled in an environment of 0-5 °C; 1.824 g of ammonium persulfate was added to the Mix with 5ml of deionized water, and after cooling to below 5°C, pour it into the above s...

Embodiment 2

[0059] (1) Dissolve 0.1g sodium chloride and 0.1g sodium dodecyl sulfate in 10ml deionized water, add 54μL hexadecyl methacrylate, stir for 3h, add 30mg graphene oxide (GO), and then add 5.3g Acrylamide (AAm), 17.2mg N,N'-methylenebisacrylamide (MBA), 0.02g sodium bicarbonate, 0.05g ammonium persulfate (APS), fully dissolved by magnetic stirring, polymerized at 45°C for 6h, prepared. Get GPH.

[0060] (2) Immerse the prepared GPH in 80ml 0.2mol / L valine for 5h, then heat at 90°C for 8h, then soak in deionized water for 48h (change deionized water every 4h), wash and remove impurities RGPH was prepared.

[0061] (3) The prepared RGPH was placed in 80ml of 0.05mol / L aniline hydrochloride solution containing 1.0mmol of phytic acid, sealed and stored for 12h, and then cooled in an environment of 0-5°C; 0.912g of ammonium persulfate was added to Mix with 5ml of deionized water, and after cooling to below 5°C, pour it into the above solution and mix evenly. After 24 hours of react...

Embodiment 3

[0063] (1) Dissolve 0.15g sodium chloride and 0.3g sodium dodecyl sulfate in 10ml deionized water, add 54μL octadecyl methacrylate, stir for 3h, add 20mg graphene oxide (GO), and then add 5.3g Acrylamide (AAm), 17.2mg N,N'-methylenebisacrylamide (MBA), 0.03g sodium bicarbonate, 0.05g ammonium persulfate (APS), fully dissolved by magnetic stirring, polymerized at 45°C for 6h, prepared. Get GPH.

[0064] (2) Immerse the prepared GPH in 80ml 0.2mol / L cysteine for 5h, then heat at 90°C for 8h, then soak in deionized water for 48h (change deionized water every 4h), wash and remove impurities RGPH was obtained after.

[0065] (3) The prepared RGPH was placed in 80ml of 0.15mol / L aniline hydrochloride solution containing 2.4mmol of phytic acid, sealed and stored for 12h, and then cooled in an environment of 0-5°C; 2.738g of ammonium persulfate was added to Mix with 5ml of deionized water, and after cooling to below 5°C, pour it into the above solution and mix evenly. After 24 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com