A chemical erosion peeling machine

A chemical erosion and peeling machine technology, applied in the field of metal bar processing equipment, can solve the company's high tool purchase costs and work injury compensation, high operating costs, short tool life and other problems, to achieve shortened maintenance time, cutting force The effect of reducing and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

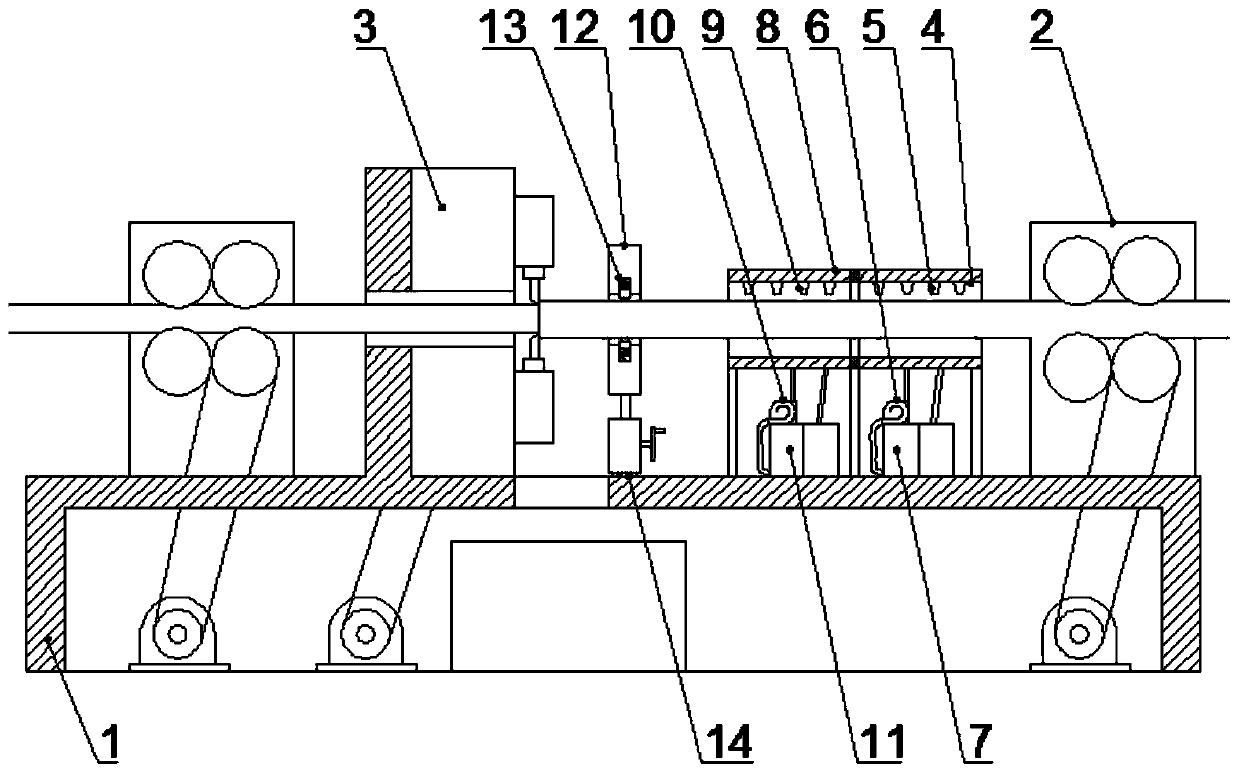

[0050] Such as figure 1 A chemical erosion peeling machine shown includes: a frame 1, a feed support mechanism 2, a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism, and a peeling mechanism 3, and the feed support mechanism 2 is arranged on both sides of the frame 1 , the frame 1 is sequentially provided with a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism and a peeling mechanism 3; the reaction mechanism includes a reaction chamber 4, a reagent nozzle 5, a liquid pump 6 and a storage box 7, and the reagent nozzle 5 is arranged inside the reaction chamber 4, a material storage box 7 is arranged below the reaction chamber 4, a liquid pump 6 is arranged on the material storage box 7, and the liquid pump 6 is connected to the liquid outlet of the material storage box 7, so that The reagent nozzle 5 is connected to the liquid pump 6 through a pipeline, and the storage tank 7 is connected to the bottom of the reaction cha...

Embodiment 2

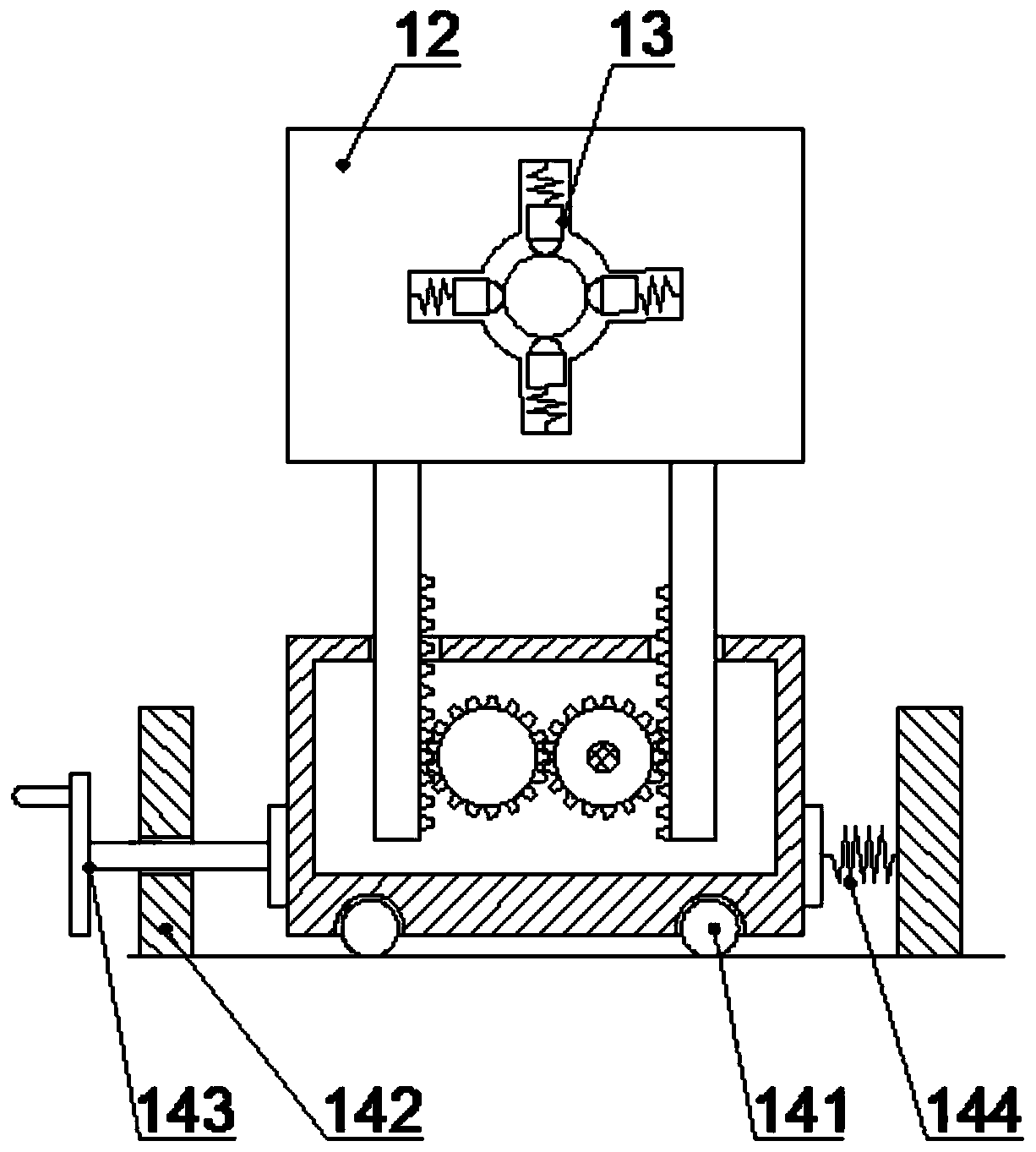

[0059] Such as figure 2 A chemical erosion peeling machine shown includes: a frame 1, a feed support mechanism 2, a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism, and a peeling mechanism 3, and the feed support mechanism 2 is arranged on both sides of the frame 1 , the frame 1 is sequentially provided with a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism and a peeling mechanism 3; the reaction mechanism includes a reaction chamber 4, a reagent nozzle 5, a liquid pump 6 and a storage box 7, and the reagent nozzle 5 is arranged inside the reaction chamber 4, a material storage box 7 is arranged below the reaction chamber 4, a liquid pump 6 is arranged on the material storage box 7, and the liquid pump 6 is connected to the liquid outlet of the material storage box 7, so that The reagent nozzle 5 is connected to the liquid pump 6 through a pipeline, and the storage tank 7 is connected to the bottom of the reaction ch...

Embodiment 3

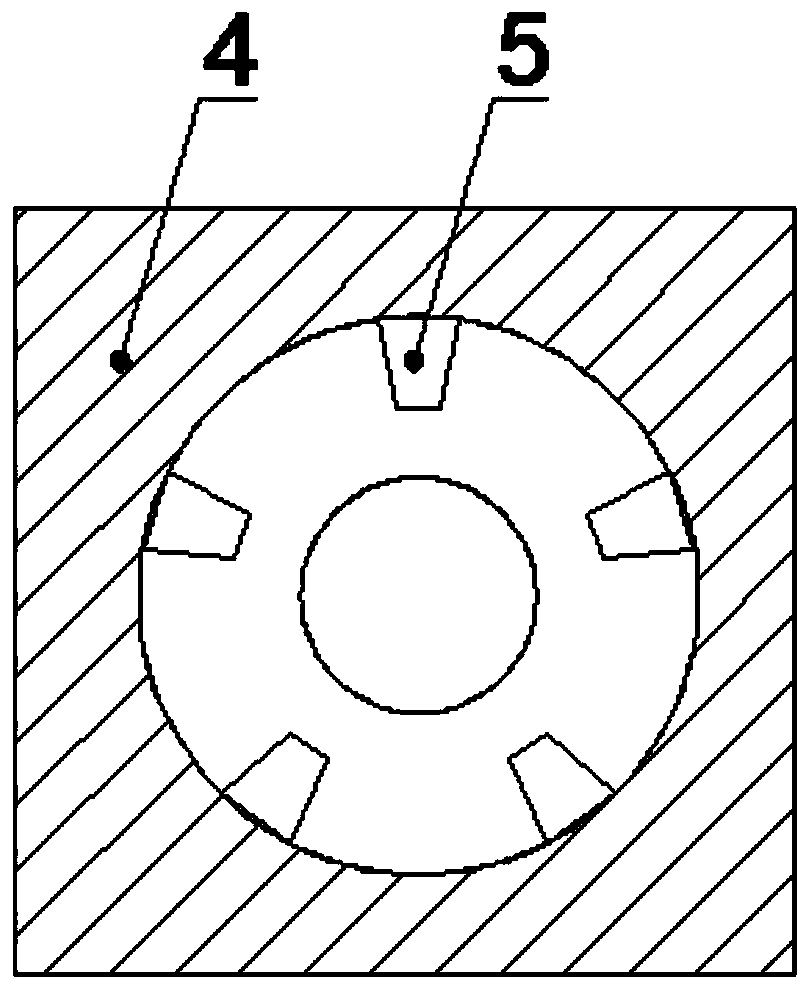

[0063] Such as image 3 A chemical erosion peeling machine shown includes: a frame 1, a feed support mechanism 2, a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism, and a peeling mechanism 3, and the feed support mechanism 2 is arranged on both sides of the frame 1 , the frame 1 is sequentially provided with a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism and a peeling mechanism 3; the reaction mechanism includes a reaction chamber 4, a reagent nozzle 5, a liquid pump 6 and a storage box 7, and the reagent nozzle 5 is arranged inside the reaction chamber 4, a material storage box 7 is arranged below the reaction chamber 4, a liquid pump 6 is arranged on the material storage box 7, and the liquid pump 6 is connected to the liquid outlet of the material storage box 7, so that The reagent nozzle 5 is connected to the liquid pump 6 through a pipeline, and the storage tank 7 is connected to the bottom of the reaction cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com