A bar peeling method using chemical solvents to protect knives

A technology using chemical and bar materials, which is applied in the field of bar peeling using chemical solvents to protect tools, can solve the problems of high tool purchase costs and work injury compensation, prone to blunt and broken knives, and short tool life. Maintenance time is reduced, damage is reduced, and the service life is extended

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

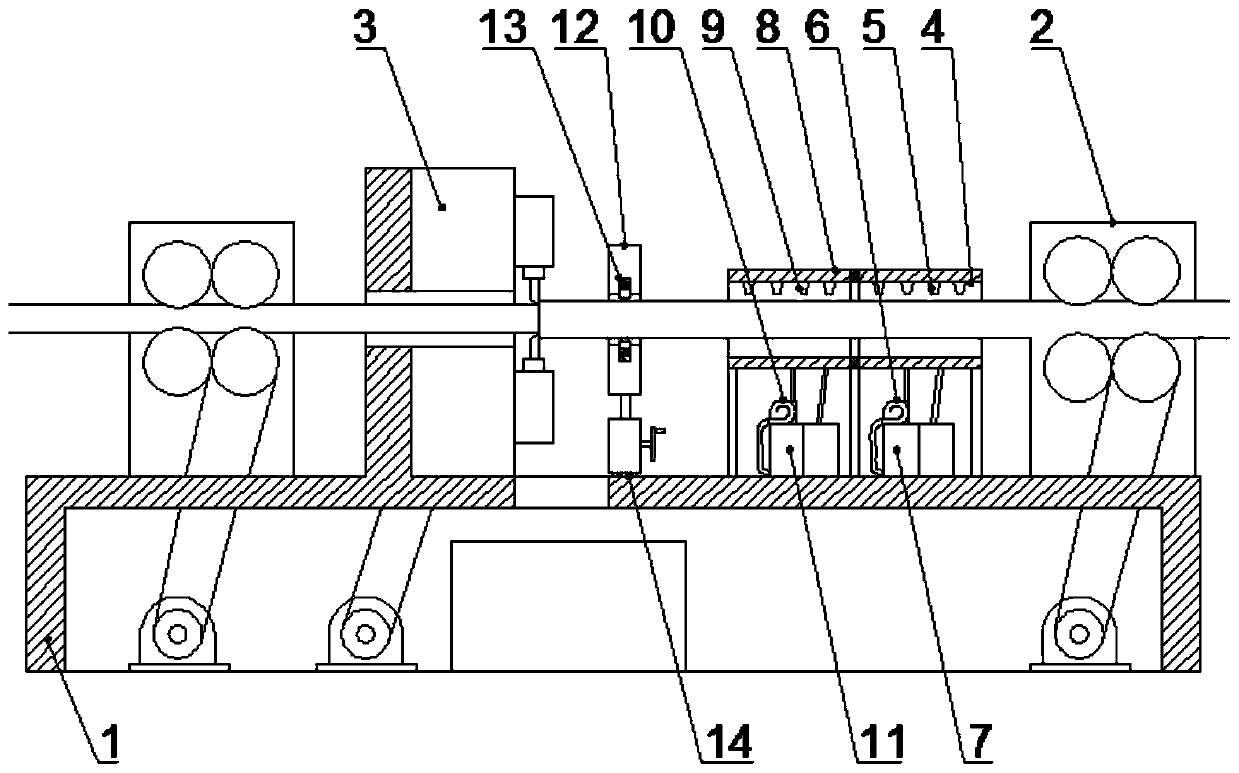

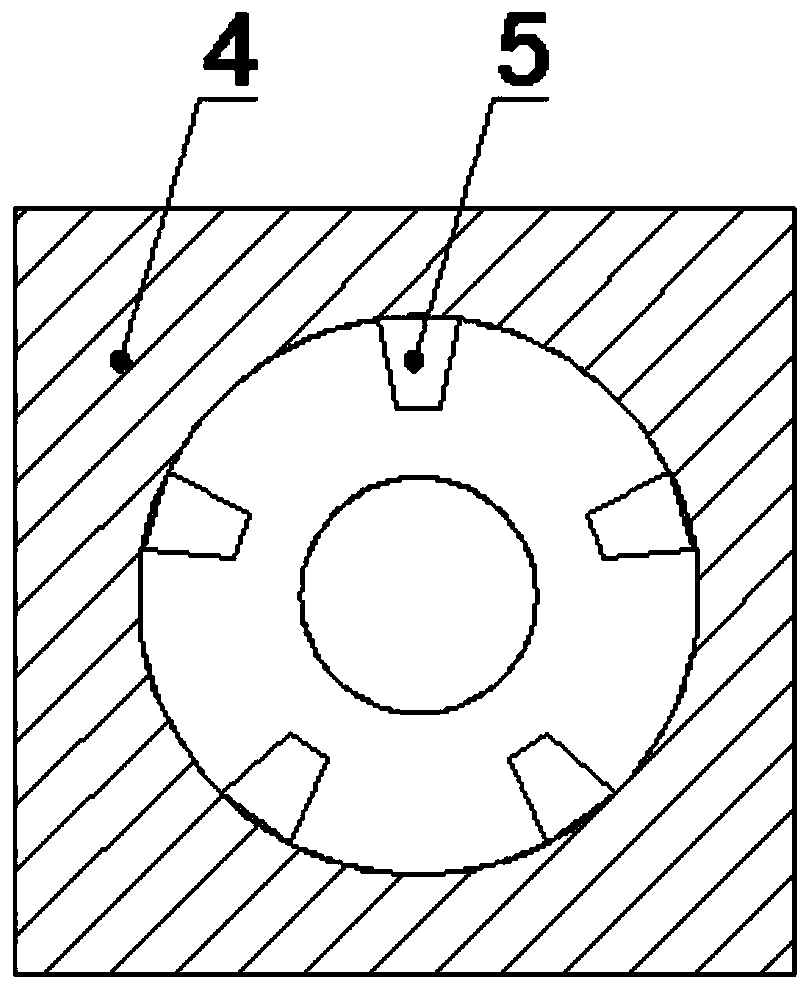

[0044] Such as figure 1 A method for stripping bar stock using a chemical solvent to protect a tool includes a frame 1 and a feed support mechanism 2, a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism, and a peeling mechanism 3 mounted on the frame 1, including the following Steps: Step 1: Prepare equipment. Feed support mechanisms 2 are provided on both sides of the frame 1, and a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism and a peeling mechanism 3 are arranged on the frame 1 in sequence; Step 2: Positioning of feeding materials, Slowly pass the bar through the reaction mechanism and the cleaning and cooling mechanism, and place it on the positioning mechanism. Move the bar through the positioning mechanism until the center line of the bar is in the same straight line with the center line of the peeling mechanism; Step 3: Start, turn on the power, and the peeling machine Start to work; Step 4: Reaction, the bar ma...

Embodiment 2

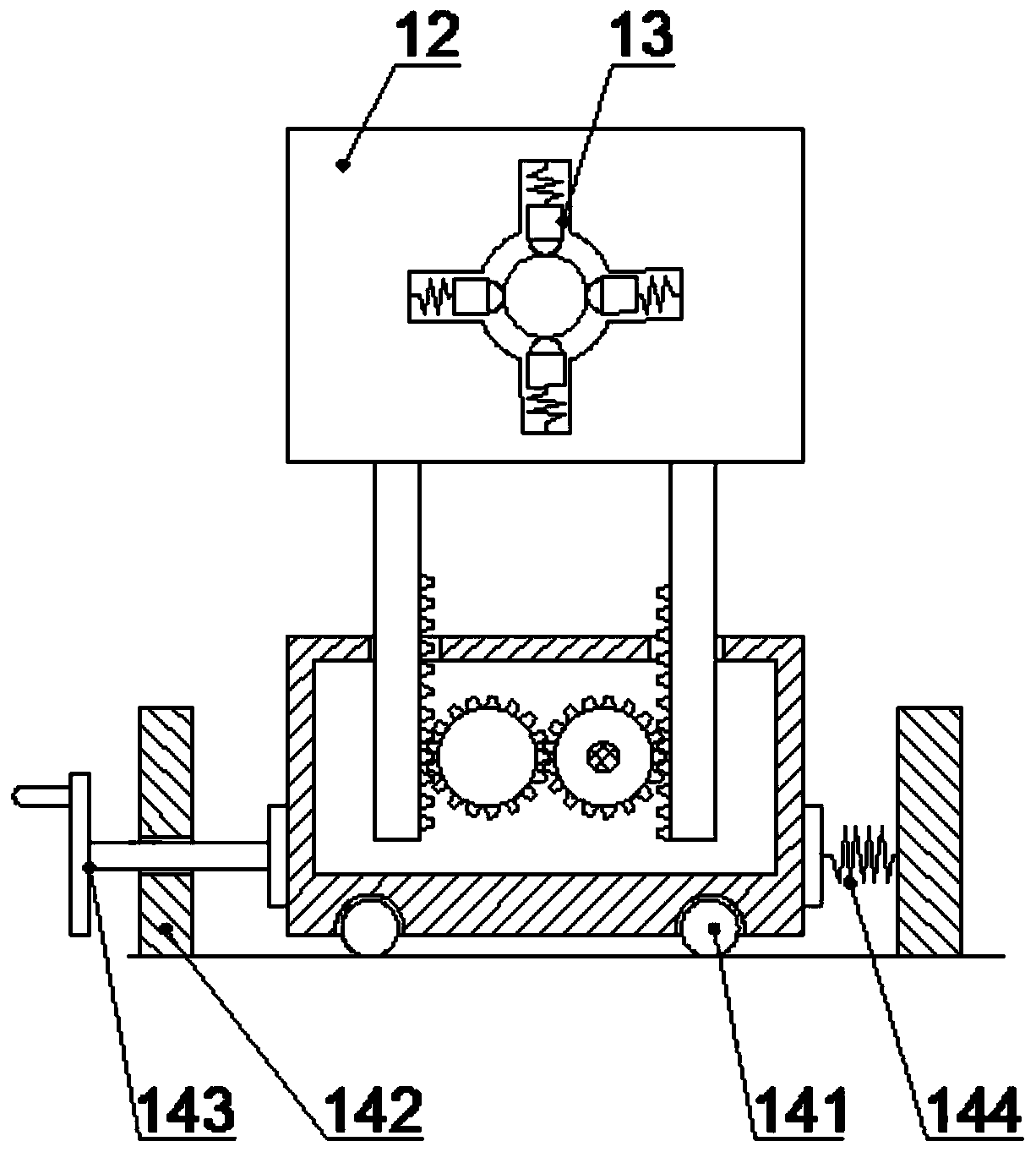

[0053] Such as figure 2 A method for stripping bar stock using a chemical solvent to protect a tool includes a frame 1 and a feed support mechanism 2, a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism, and a peeling mechanism 3 mounted on the frame 1, including the following Steps: Step 1: Prepare equipment. Feed support mechanisms 2 are provided on both sides of the frame 1, and a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism and a peeling mechanism 3 are arranged on the frame 1 in sequence; Step 2: Positioning of feeding materials, Slowly pass the bar through the reaction mechanism and the cleaning and cooling mechanism, and place it on the positioning mechanism. Move the bar through the positioning mechanism until the center line of the bar is in the same straight line with the center line of the peeling mechanism; Step 3: Start, turn on the power, and the peeling machine Start to work; Step 4: Reaction, the bar m...

Embodiment 3

[0057] Such as figure 1 A method for stripping bar stock using a chemical solvent to protect a tool includes a frame 1 and a feed support mechanism 2, a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism, and a peeling mechanism 3 mounted on the frame 1, including the following Steps: Step 1: Prepare equipment. Feed support mechanisms 2 are provided on both sides of the frame 1, and a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism and a peeling mechanism 3 are arranged on the frame 1 in sequence; Step 2: Positioning of feeding materials, Slowly pass the bar through the reaction mechanism and the cleaning and cooling mechanism, and place it on the positioning mechanism. Move the bar through the positioning mechanism until the center line of the bar is in the same straight line with the center line of the peeling mechanism; Step 3: Start, turn on the power, and the peeling machine Start to work; Step 4: Reaction, the bar ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com