Bar peeling method for protecting cutter by using chemical solvent

A technology using chemical and bar materials, applied in the field of bar material peeling where chemical solvents are used to protect tools, can solve the problems of high tool purchase costs and work-related injury compensation, prone to dull and broken tools, and short tool life, and shorten the tool life. The effect of repairing time, reducing damage and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

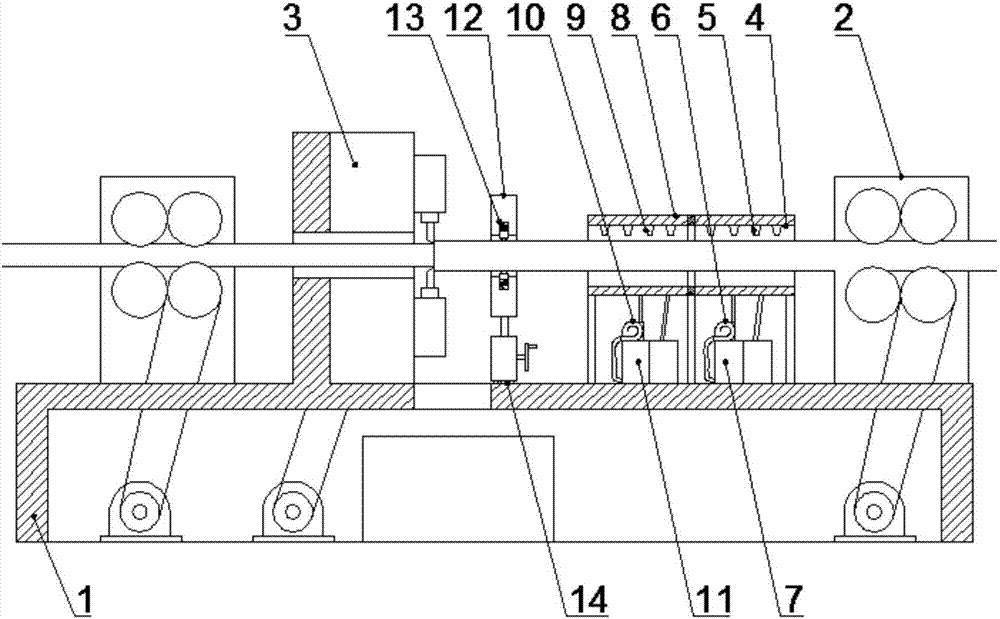

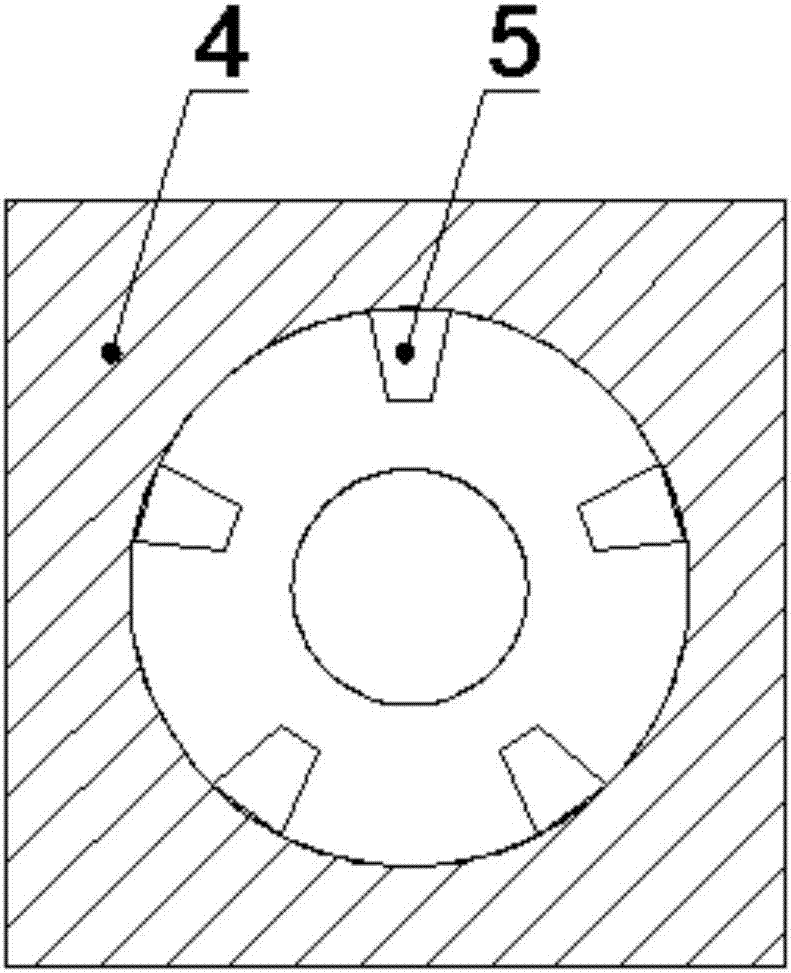

[0044] like figure 1 A bar peeling method using a chemical solvent to protect the cutting tool is shown, including a frame 1 and a feed support mechanism 2 installed on the frame 1, a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism, and a peeling mechanism 3, including the following Steps: Step 1: Prepare equipment, set feed support mechanism 2 on both sides of frame 1, and set reaction mechanism, cleaning and cooling mechanism, positioning mechanism and peeling mechanism 3 on frame 1 in sequence; Step 2: Loading and positioning, Slowly pass the bar material through the reaction mechanism and the cleaning and cooling mechanism, put it on the positioning mechanism, and move the bar material through the positioning mechanism until the center line of the bar material is in the same line as the center line of the peeling mechanism; Step 3: Start, turn on the power, and peel the machine Start to work; Step 4: Reaction, the bar enters the reaction mecha...

Embodiment 2

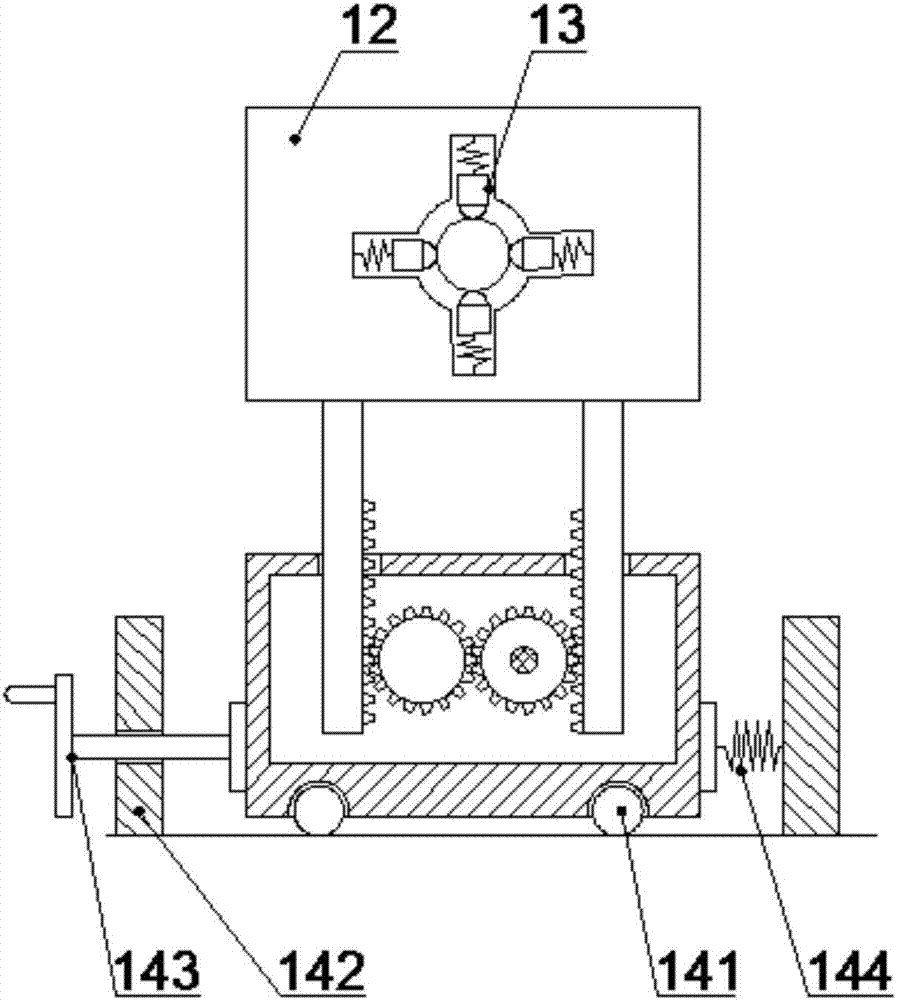

[0053] like figure 2 A bar peeling method using a chemical solvent to protect the cutting tool is shown, including a frame 1 and a feed support mechanism 2 installed on the frame 1, a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism, and a peeling mechanism 3, including the following Steps: Step 1: Prepare equipment, set feed support mechanism 2 on both sides of frame 1, and set reaction mechanism, cleaning and cooling mechanism, positioning mechanism and peeling mechanism 3 on frame 1 in sequence; Step 2: Loading and positioning, Slowly pass the bar material through the reaction mechanism and the cleaning and cooling mechanism, put it on the positioning mechanism, and move the bar material through the positioning mechanism until the center line of the bar material is in the same line as the center line of the peeling mechanism; Step 3: Start, turn on the power, and peel the machine Start to work; Step 4: Reaction, the bar enters the reaction mech...

Embodiment 3

[0057] like figure 1 A bar peeling method using a chemical solvent to protect the cutting tool is shown, including a frame 1 and a feed support mechanism 2 installed on the frame 1, a reaction mechanism, a cleaning and cooling mechanism, a positioning mechanism, and a peeling mechanism 3, including the following Steps: Step 1: Prepare equipment, set feed support mechanism 2 on both sides of frame 1, and set reaction mechanism, cleaning and cooling mechanism, positioning mechanism and peeling mechanism 3 on frame 1 in sequence; Step 2: Loading and positioning, Slowly pass the bar material through the reaction mechanism and the cleaning and cooling mechanism, put it on the positioning mechanism, and move the bar material through the positioning mechanism until the center line of the bar material is in the same line as the center line of the peeling mechanism; Step 3: Start, turn on the power, and peel the machine Start to work; Step 4: Reaction, the bar enters the reaction mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com