Drawing machine for textile fiber strips

A technology for fiber strips and cans, used in spinning machines, textiles and papermaking, drafting equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

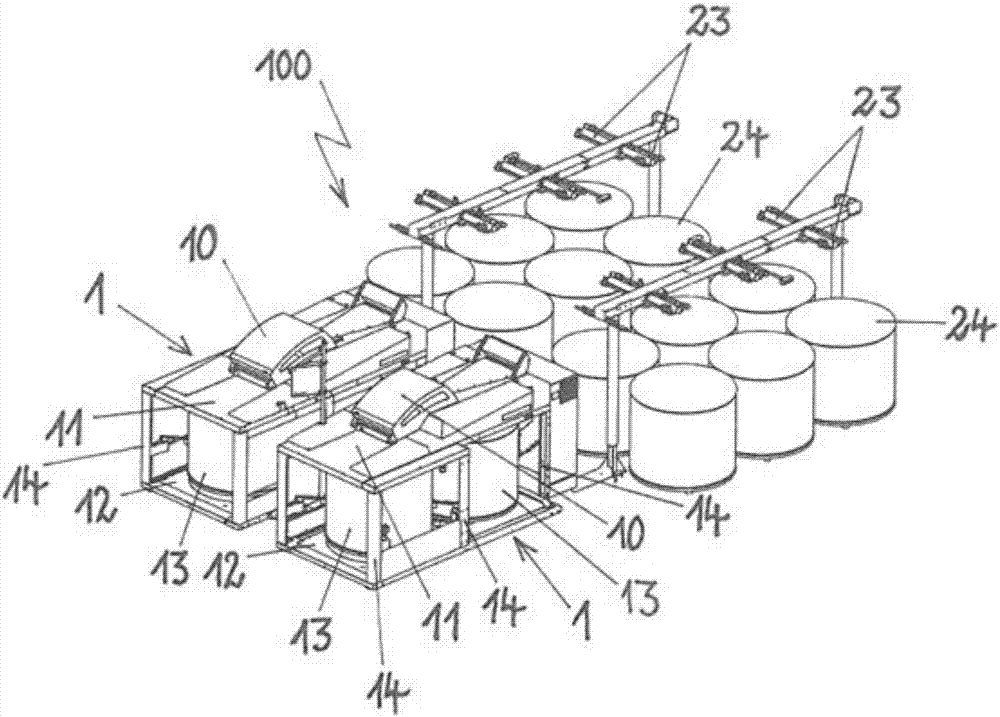

[0025] figure 1 A perspective view shows a draw frame 100 , which is designed as a double-head draw frame and includes two draw frames 1 . Arranged upstream of the two drawing frames 1 is a creel 23 of the creel arrangement, which guides the woven fiber sliver, not shown in detail, from the can 24 and feeds it to the drawing frame 1 . The woven sliver enters the drafting system 10 in which a plurality of slivers (six slivers from six cans 24 of each drawing frame 1 in the illustrated embodiment) They are placed side by side, and these fiber slivers are drawn into new, single fiber slivers, for example having the same cross-section as the respective fiber slivers from the can 24 . The example shows six cans 24 per drawing frame 1 and each can 24 preferably likewise has a diameter of 1200 mm.

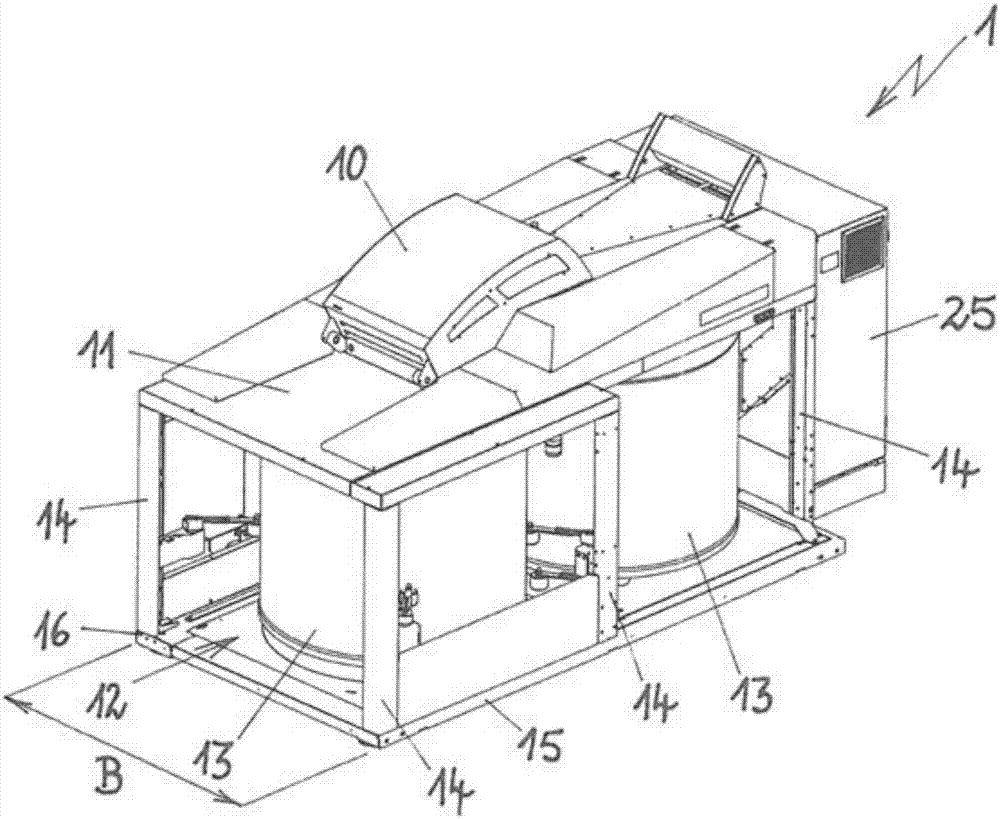

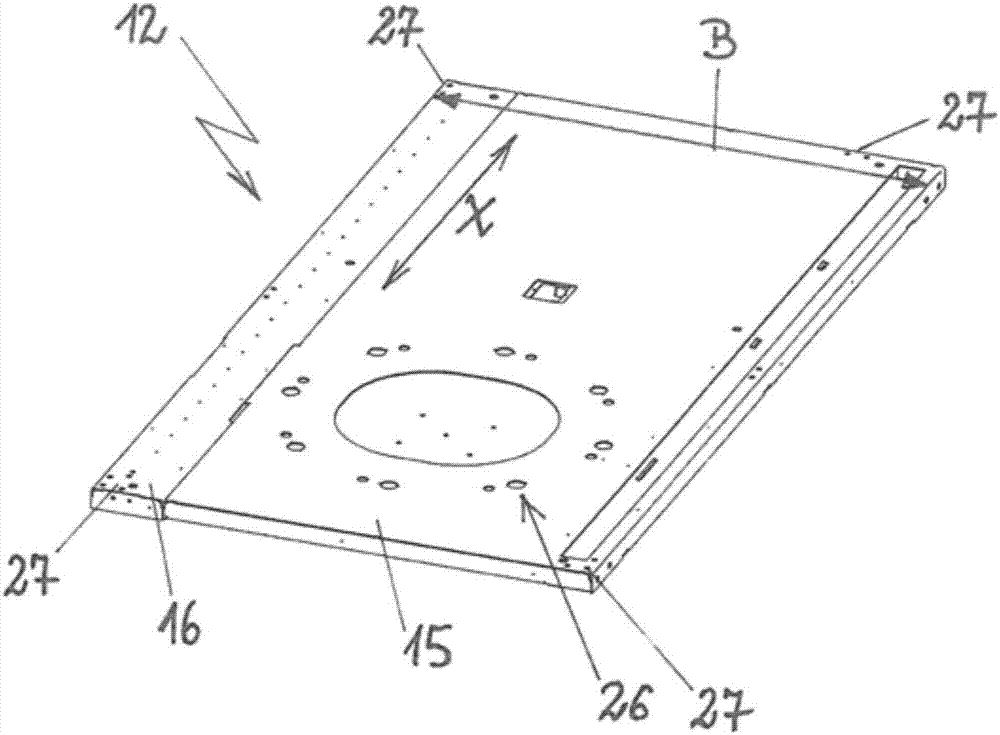

[0026] The drawing frame 1 has a basic structure consisting of a coil housing 11 on which the drafting system 10 is accommodated. On the underside there is a base plate 12 , and the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com