Color-changing textile and spinning method thereof

A textile, heat-sensitive discoloration technology, applied in the field of textiles, can solve problems such as damage, life-threatening, misjudgment or operation, and achieve scientific and reasonable results in the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0019] Example: such as figure 1 As shown, the present invention provides a color-changing textile, in which a photosensitive color-changing material is added to the textile fiber, the outer side of the textile fiber is coated with a heat-insulating coating, and the outer side of the thermal-insulating coating is coated with an antistatic coating.

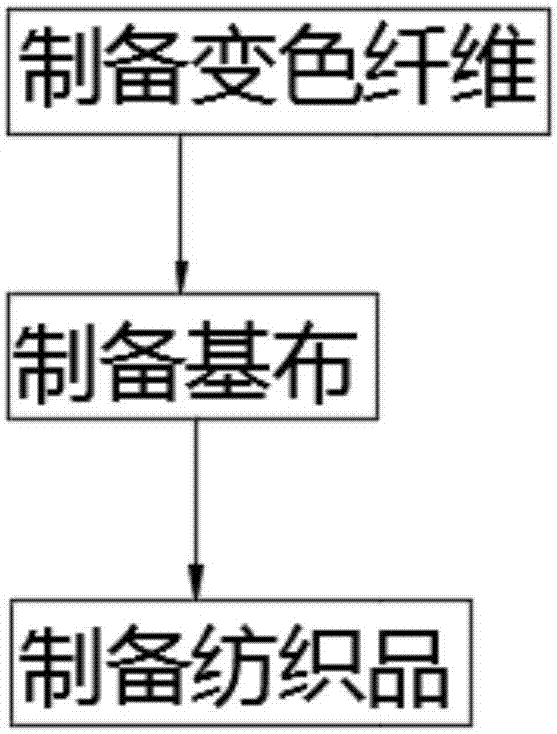

[0020] A method for weaving color-changing textiles, comprising the steps of:

[0021] 1) Preparation of color-changing fibers: adding photosensitive materials to fibers by solution spinning to obtain color-changing fibers;

[0022] 2) Preparing the base cloth: weaving the obtained discoloration fiber through a textile machine to obtain the base cloth;

[0023] 3) Preparation of textiles: pre-treatment of the base cloth: do the pre-treatment of the textiles and use it as a base cloth; add heat-insulating coatings on the surface of the prepared base cloth; bake the base cloth with heat-insulating coatings Drying, the drying temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com