Roadbed compaction degree detecting device

A detection device and technology of compaction degree, which are applied in the field of foundation soil survey, infrastructure engineering, construction, etc., can solve the problem of inconvenient soil sample collection, inaccurate test results of roadbed compaction degree, extension of roadbed and pavement engineering use. Life and other issues, to achieve the effect of reducing the forward resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

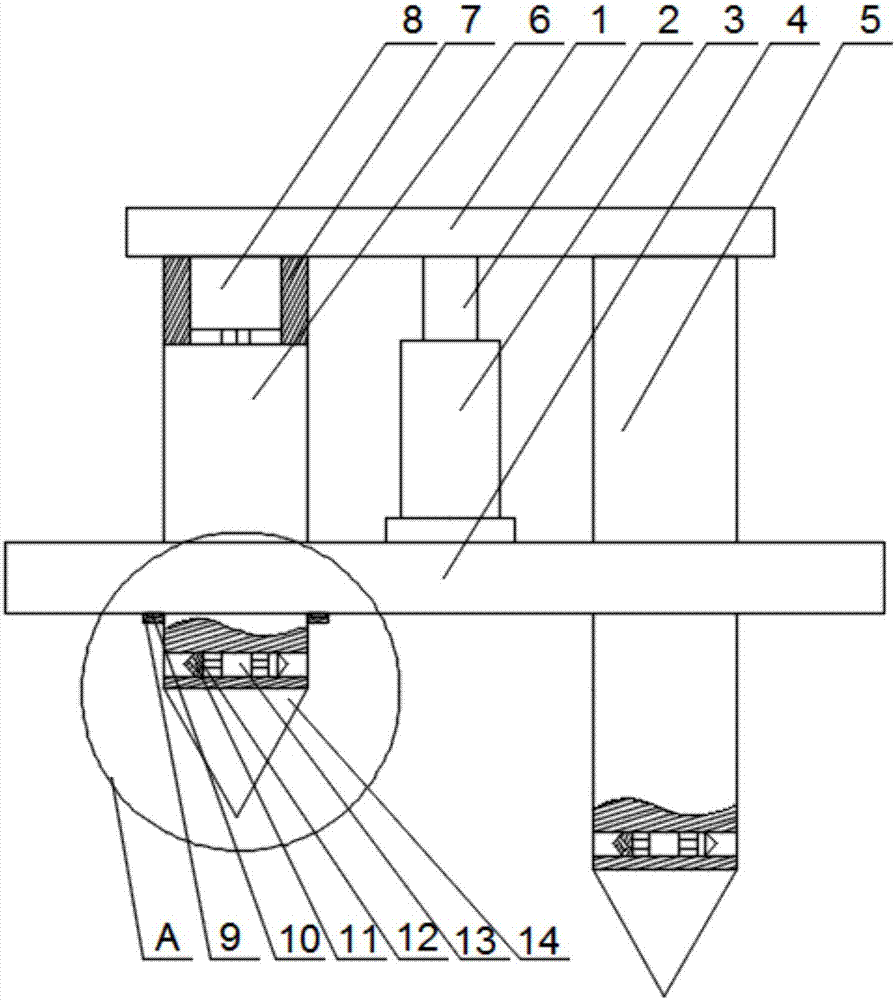

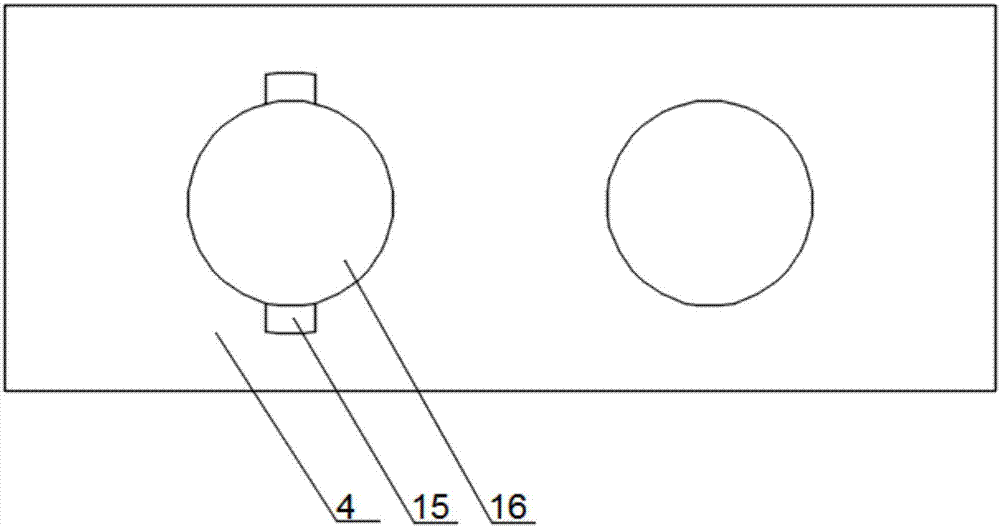

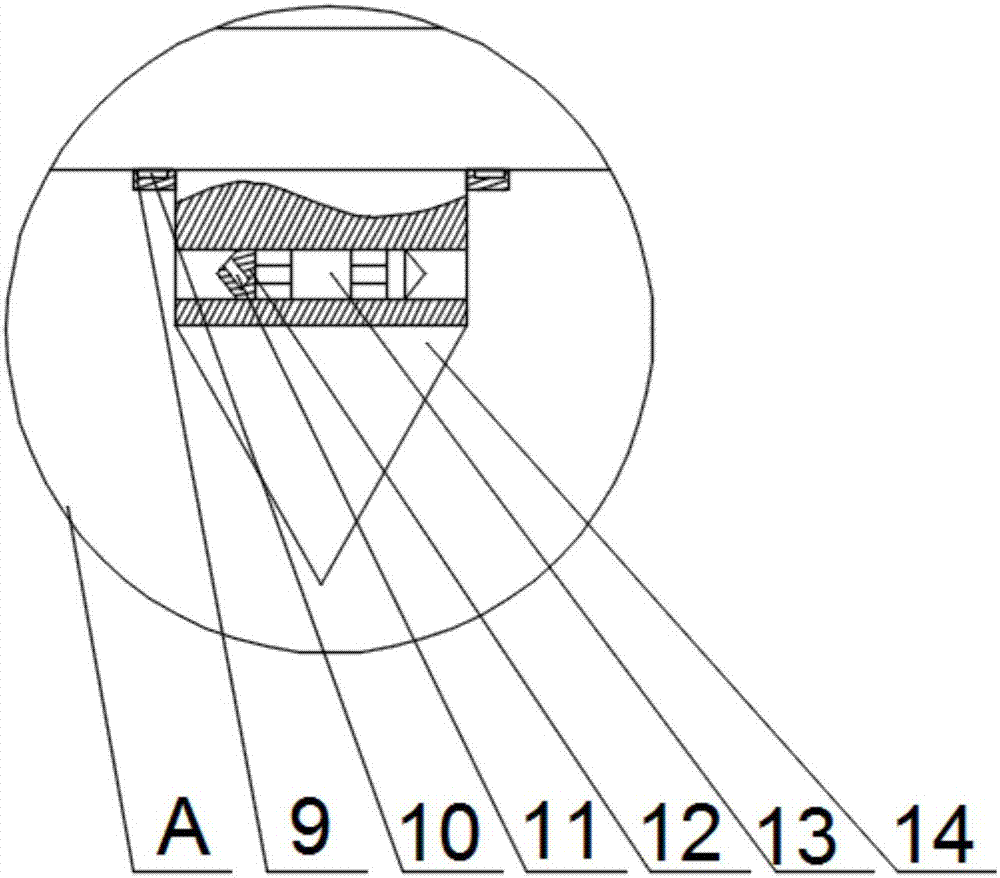

[0025] Such as Figure 1~3As shown, the present embodiment includes a base plate 3 and a hydraulic cylinder 3 vertically arranged on the upper surface of the base plate 3. On the output end of the hydraulic cylinder 3, a lower pressing plate 1 parallel to the base plate 3 is fixed. On the lower surface of the lower pressing plate 1 One end is fixed with a long column 5, and the other end of the lower surface of the lower platen 1 is provided with a fixed cylinder 7. The motor 8 is installed in the fixed cylinder 7, and the output end of the motor 8 is connected with a short column 6 parallel to the long column 5. Two through holes 15 are respectively opened on the bottom plate 3, and the two through holes 15 are respectively centered with the long column 5 and the short column 6, and the long column 5 and the short column 6 pass through the through hole 15 respectively and then move toward the vertical direction. Extending away from the direction of the lower surface of the bo...

Embodiment 2

[0030] Such as Figure 1~3 As shown, the longitudinal section of the driving head 12 in this embodiment is an acute triangle, and the plane where the long side of the driving head 12 is located is connected to the output end of the two-way cylinder 13, and the blind hole 11 is opened on the short side of the driving head 12. and the axis of the blind hole 11 is inclined from bottom to top along the axis of the short column 6 in a direction away from the axis of the short column 6 . Further, the two excavating heads 12 on the long column 5 or the short column 6 are synchronously pushed outwards to realize the collection of soil samples, while the horizontally moving excavating heads 12 will be subject to greater resistance, for which the applicant will The driving head 12 is arranged as a triangular block, and the compacted layer is rapidly advanced by using the sharp corner of the triangular block, and the blind hole 11 is opened on the plane where the short side of the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com