Glass fiber reinforced polyester corrugated plate impact performance test device

A glass fiber and impact performance technology, which is applied in the field of glass fiber reinforced polyester corrugated board impact performance testing devices, can solve the problems of automation degree, low testing quality and efficiency, complicated operation, and many human interference factors, etc. The effect of automation, easy operation and elimination of human interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

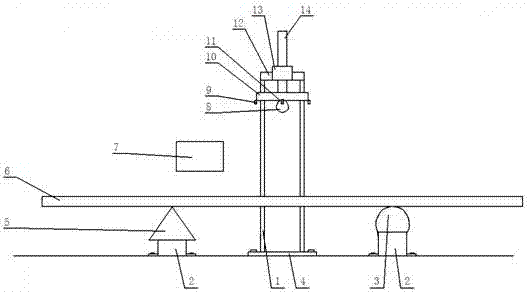

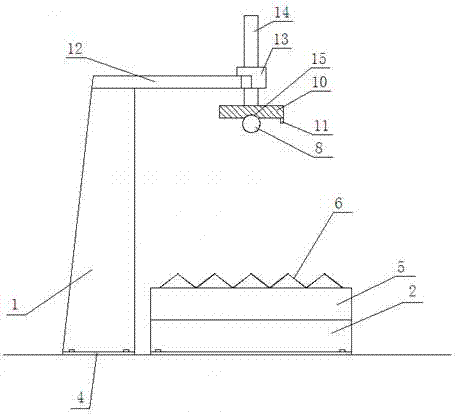

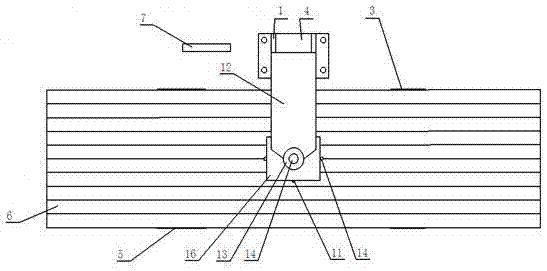

[0020] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a frame 1, a height adjustment device is fixed on the extension of the upper end of the frame 1, and a steel ball 8 release device is fixed on the lower end of the height adjustment device; The support bar of the ester corrugated plate sample 6; the laser range finder 9 and the monitoring camera 11 are installed on the steel ball 8 release device, and the laser range finder 9 and the monitoring camera 11 are respectively connected to the display PLC controller 7. The upper end extension of the frame 1 is a frame top plate 12 fixed on the top of the frame 1 .

[0021] The height adjustment device includes a telescopic shaft motor 13 fixed on the frame top plate 12, and the telescopic shaft 14 lower end of the telescopic shaft motor 13 is fixed with a steel ball 8 release device; the telescopic shaft motor 13 is connected with a display PLC controller 7.

[0022] Stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com