Testing device and method for permeability coefficient evolution of fractured rock mass

A technology of permeability coefficient and fractured rock mass, which is applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., which can solve the problem of small shear displacement and pressure value, inability to test permeability characteristics and deformation and failure characteristics, etc. problem, to achieve the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

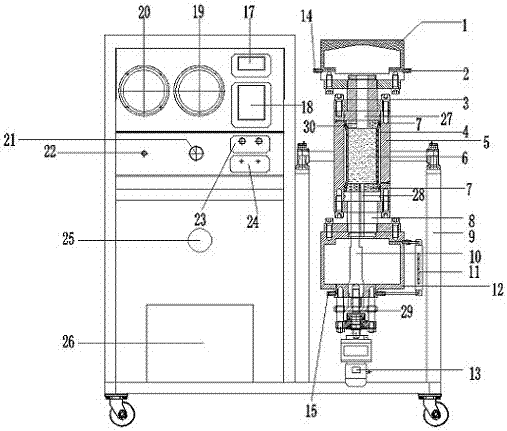

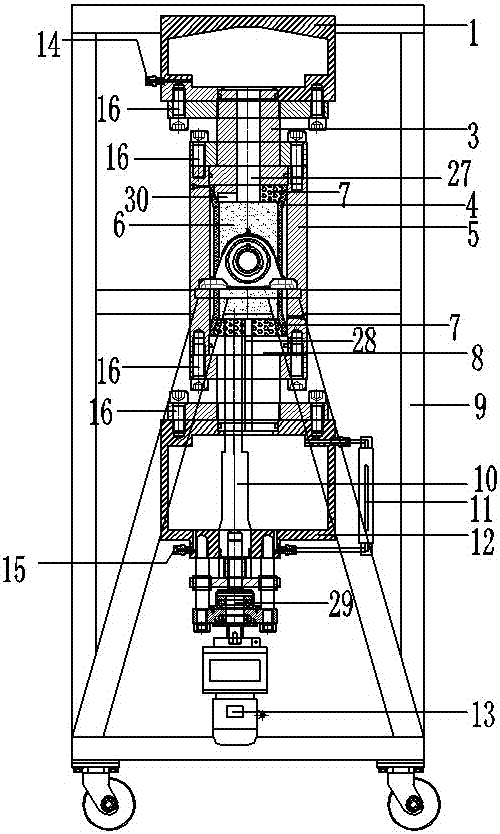

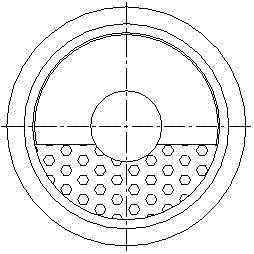

[0026] refer to figure 1 As shown, the test device of the present invention comprises a rock core holder 5 and a water injection tank 1 positioned above the rock core holder 5, and a water storage tank 12 below the rock core holder 5. In the present embodiment, the water injection tank 1 and The core holder 5 is connected with the water seepage pad 7 (high permeability pad) through the upper plug 3, and the water storage tank 12 and the core holder 5 are connected through the lower plug 8 and the water seepage pad 7 (high permeability pad). Block) connection; the core holder 5 is connected to the steel bracket 8 through the supporting rotating rod assembly provided on the side to play a supporting role.

[0027] The supporting rotating rod assembly includes a bearing and a bearing seat fixed on the steel bracket 8. By fixing the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com