A kind of soft magnetic composite powder and its application

A technology of soft magnetic composite and soft magnetic composite materials, which is applied in the field of powder metallurgy and magnetic material preparation, can solve the problems without careful consideration, achieve the effect of reducing oxygen deficiency, improving magnetic and mechanical properties, and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

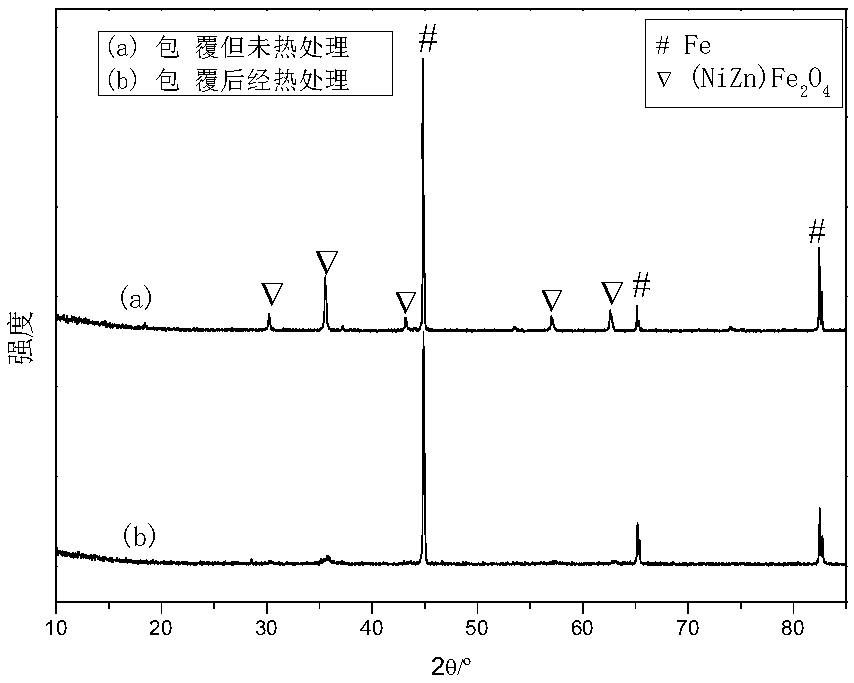

[0055] With (NiZn)Fe 2 o 4 The content of coating in / Fe is 1.5wt% for proportioning and coating. Press Ni 0.5 Zn 0.5 Fe 2 o 4 Chemical formula ratio, the weighed reagent FeCl 3 ﹒ 6H 2 O, NiCl 2 ﹒ 6H 2 O and ZnCl 2 Dissolve in 75ml deionized water, stir and mix evenly with a glass rod to make solution A. At the same time, dissolve the reagent KOH in 75ml of deionized water, mix well to make alkaline solution B. In addition, a corresponding amount of pure iron powder with an average particle size of 30 um was added to 300 ml of deionized water to obtain a suspension C. So far, the preparatory work before the reaction is completed. During the reaction, drop the prepared solution A and alkali solution B into the suspension C at a speed of about 5ml / min at the same time, and at the same time, use a mechanical stirrer to continuously stir the suspension C to make it fully react, about 15min After the reaction was finished, let it stand for precipitation, and rinse th...

Embodiment 2

[0075] With (MnZn)Fe 2 o 4 / Fe 3.5 The content of coating in Si is 3wt% for proportioning and coating. Press Mn 0.4 Zn 0.6 Fe 2 o 4 Chemical formula ratio, the weighed reagent FeCl 3 ﹒ 6H 2 O, MnCl 2 ﹒ 4H 2 O and ZnCl 2Dissolve in 80ml deionized water, stir and mix evenly with a glass rod to make solution A. At the same time, dissolve the reagent NaOH in 80ml of deionized water, mix well to make alkaline solution B. In addition, a corresponding amount of Fe-3.5Si powder with an average particle size of 24um was added to 300ml of deionized water to obtain a suspension C. So far, the preparatory work before the reaction is completed. During the reaction, drop the prepared solution A and alkaline solution B into the suspension C at a speed of about 10ml / min at the same time, and at the same time, use a mechanical stirrer to continuously stir the suspension C to make it fully react, about 10min After the reaction was finished, let it stand for precipitation, and ri...

Embodiment 3

[0081] With (MnZn)Fe 2 o 4 The content of the coating in / FeSiAl is 1wt% for proportioning and coating. Press Mn 0.8 Zn 0.2 Fe 2 o 4 Chemical formula ratio, the weighed reagent Fe(NO 3 ) 3 ﹒ 9H 2 O, Mn(NO 3 ) 2 ﹒ 4H 2 O and Zn(NO 3 ) 2 ﹒ 6H 2 Dissolve O in 100ml deionized water, stir and mix evenly with a glass rod to make solution A. At the same time, dissolve the reagent NaOH in 100ml of deionized water, mix well to make alkaline solution B. In addition, a corresponding amount of Fe-9Si-6Al powder with an average particle size of 42um was added to 300ml of deionized water to obtain a suspension C. So far, the preparatory work before the reaction is completed. During the reaction, drop the prepared solution A and alkaline solution B into the suspension C at a rate of about 3ml / min at the same time, and at the same time, use a mechanical stirrer to continuously stir the suspension C to make it fully react, about 20min After the reaction was finished, let it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com