Engine hood of passenger car

A technology for hoods and passenger cars, which is applied to power units, vehicle components, and the arrangement of cooling combination of power units, etc., can solve the problems of low heat dissipation efficiency and weak controllability, and achieve high heat dissipation efficiency, strong controllability, and improved heat dissipation efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

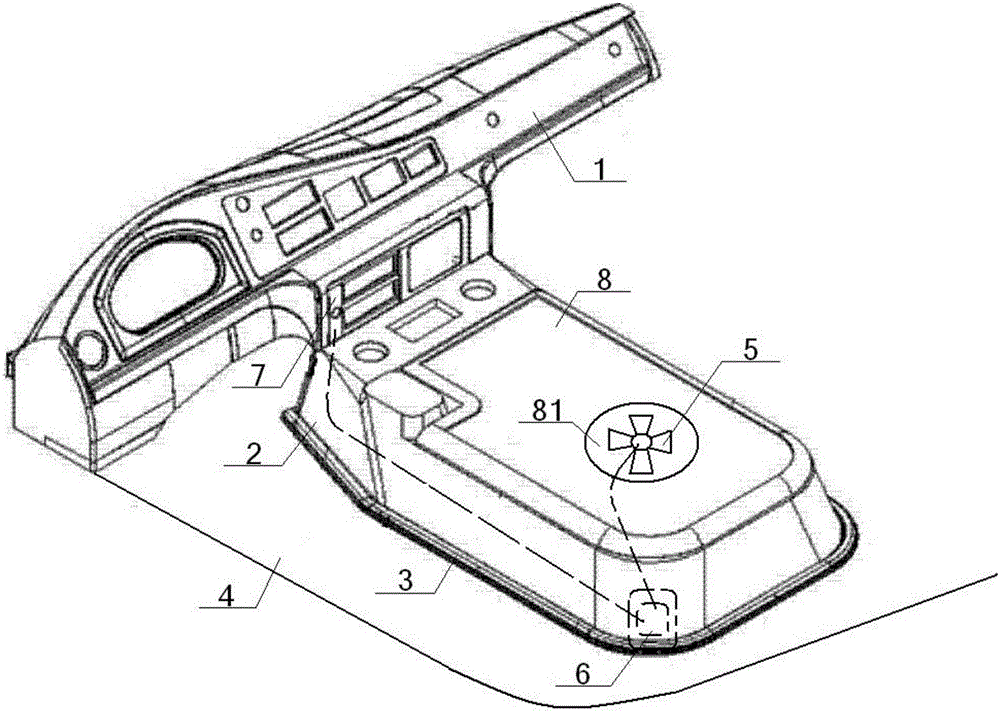

[0020] see figure 1 – figure 2 , a passenger car engine cover, comprising a top cover 8, a base 2 and a damping strip 3, the top of the base 2 is provided with a top cover 8, and the bottom edge of the base 2 is connected to the floor 4 through the damping strip 3, and The front end of the base 2 is connected with the instrument assembly 1;

[0021] The top cover 8 is provided with a cooling hole 81, the cooling fan 5 is arranged in the cooling hole 81, and the cooling fan 5 is connected with the power supply 7 circuit after the controller 6, and the controller 6 is arranged on the base 2 away from the instrument One end of the assembly 1, the power supply 7 is set on the base 2 near the end of the instrument assembly 1;

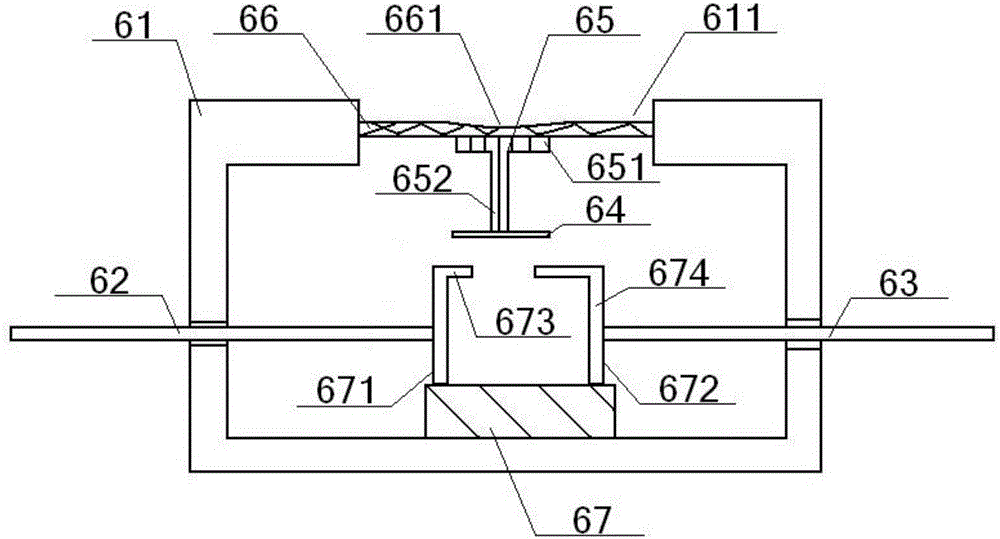

[0022] Described controller 6 comprises metal casing 61, input power line 62, output power line 63, energizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com