Method for preparing foamed ceramics by utilizing sludge pyrolytic residues and equipment by utilizing method

A technology of foam ceramics and pyrolysis, which is applied in the field of resource utilization of solid waste, can solve the problem of high raw material cost, achieve the effects of reduced production cost, high degree of automation, and simple source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

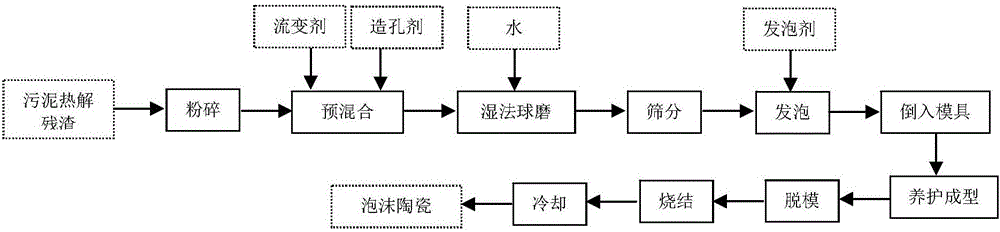

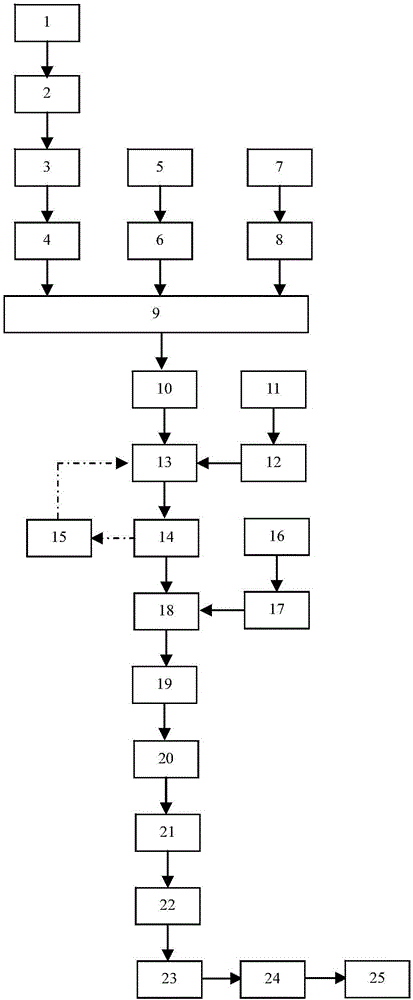

[0047] like figure 1 As shown, crush the sludge pyrolysis residue obtained by carbonization at 600°C for 30 minutes to make the particle size 3 In the cylindrical mold, a stable foam molding material is formed after curing. Then put the foam molding material into a curing box at 70°C for 24 hours to obtain a sintered billet; put the sintered billet into a high-temperature sintering furnace, raise the temperature to 1050°C at a rate of 5°C / min, and sinter for 30 minutes to -1 , 271.44mg·kg -1 , 0.084mg·kg -1 , 0.24mg·kg -1 , 0.029mg·kg -1 , far lower than the limit value stipulated in the national standard GB5085.3-2007 for identification of leaching toxicity, and can be used safely.

Embodiment 2

[0049] Crush the sludge pyrolysis residue obtained by carbonization at 650°C for 30 minutes to make the particle size 3 In the cylindrical mold, a stable foam molding material is formed after curing. Then put the foam molding material into a curing box at 60°C for 24 hours to obtain a sintered billet; put the sintered billet into a sintering muffle furnace, raise the temperature to 1050°C at a rate of 5°C / min, and sinter for 30 minutes. The cooling rate of -1 , 250.33mg·kg -1 , 0.077mg·kg -1 , 0.219mg·kg -1 , 0.027mg·kg -1 , far lower than the limit value stipulated in the national standard GB5085.3-2007 for identification of leaching toxicity, and can be used safely.

Embodiment 3

[0051] Pulverize the sludge pyrolysis residue obtained by carbonization at 700°C for 30 minutes to make the particle size 3 In the cylindrical mold, a stable foam molding material is formed after curing. Then put the foam molding material into a curing box at 60°C for 24 hours to obtain a sintered billet; put the sintered billet into a high-temperature sintering furnace, raise the temperature to 1050°C at a rate of 5°C / min, and sinter for 30 minutes to -1 , 229.22mg·kg -1 , 0.071mg·kg -1 , 0.20mg·kg -1 , 0.024mg·kg -1 , far lower than the limit value stipulated in the national standard GB5085.3-2007 for identification of leaching toxicity, and can be used safely.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com