Precise two-point leakage detection locating method for pressure pipeline

A leak detection and pressure pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problem of low leakage source positioning accuracy, complex pipeline conditions and environmental noise, pipeline leakage signals difficult to identify and Extraction etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be described in detail in conjunction with accompanying drawing now. This figure is a simplified schematic diagram only illustrating the basic structure of the present invention in a schematic manner, so it only shows the components relevant to the present invention.

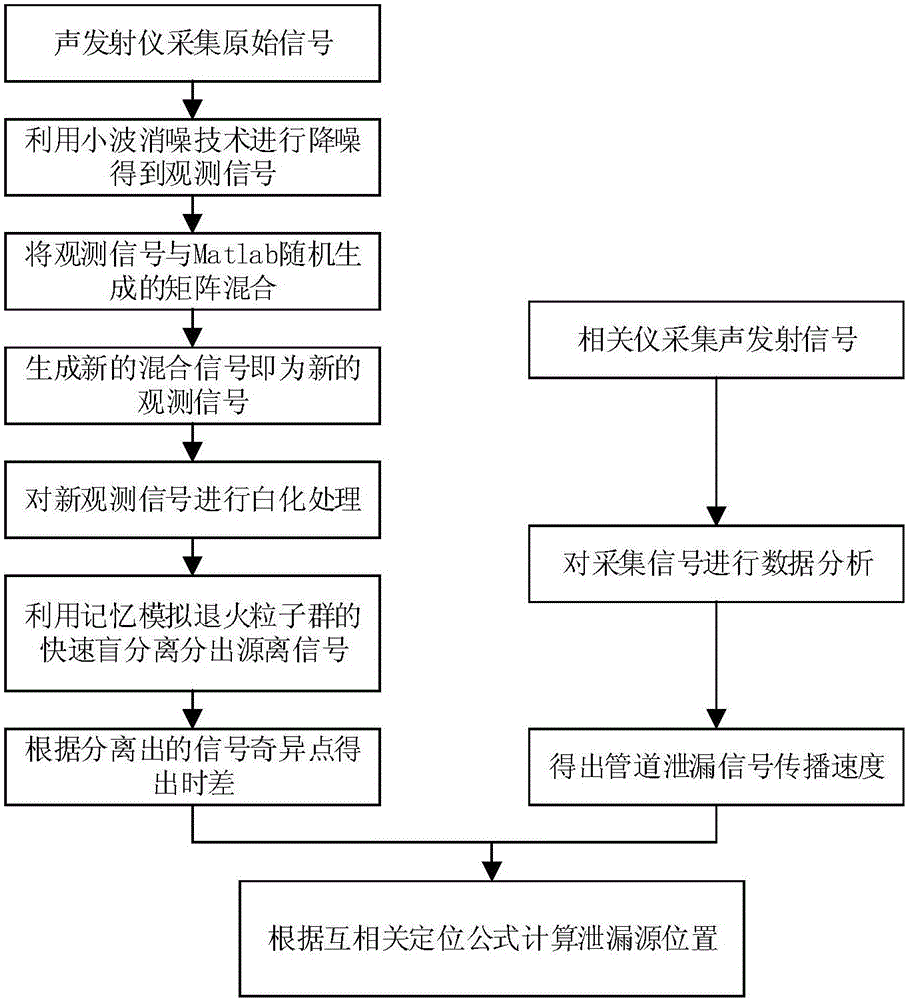

[0084] Such as figure 1 Shown, a kind of pressure pipeline two-point leak detection accurate positioning method of the present invention, specifically comprises the following steps,

[0085] S1: Build a detection system;

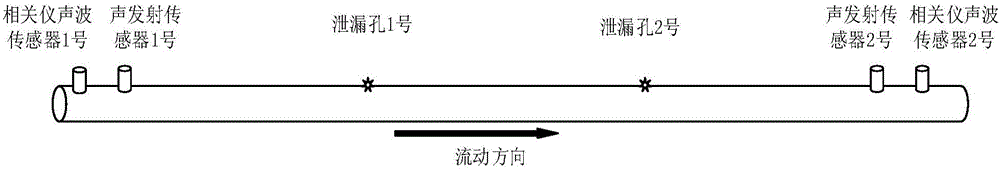

[0086] Install two acoustic emission sensors on the upstream and downstream of the pipeline to be tested, and connect the acoustic emission sensors to the acoustic emission instrument to build an acoustic emission leak detection system; at the same time, install the two correlator sensors on the same upstream and downstream of the pipeline to be tested position, and connect the two sensors with the correlator to build a correlator leak detection system;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com