Ultra-low temperature heat-exchange device of air source unit

A heat exchange device and air source technology, applied in refrigeration components, fluid heaters, climate sustainability, etc., can solve problems such as large maintenance space, insufficient space to meet requirements, and unselectable connection direction, etc., to achieve simple engineering installation, Small unit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

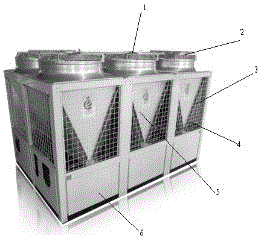

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

[0011] Referring to the accompanying drawings, the present invention relates to a storage management software system based on a mobile phone client. The system includes five parts: a compressor, a working medium, an evaporator, a cold and heat exchanger, and a throttling device; it is characterized in that: the air source heat pump Working procedure The low-temperature and low-pressure air-side heat exchanger absorbs the heat in the air and evaporates; the refrigerant becomes a low-temperature and low-pressure gas, which is then compressed by a compressor through a small amount of electric energy input; the high-temperature and high-pressure gaseous refrigerant Heat exchange with the cold water in the exchanger; the high-pressure liquid refrigerant is decompressed through the throttling mechanism; the cold water is heated until the hot water of the required temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com