10 kV medium voltage cable hot-line work safety analysis method and system

A technology of safety analysis and live operation, applied in the field of power grid, can solve problems such as difficulty, complicated calculation, affecting the selection of arc suppression measures, etc., to achieve the effect of ensuring safe development and simple and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1 does not consider operator experience and environmental factors.

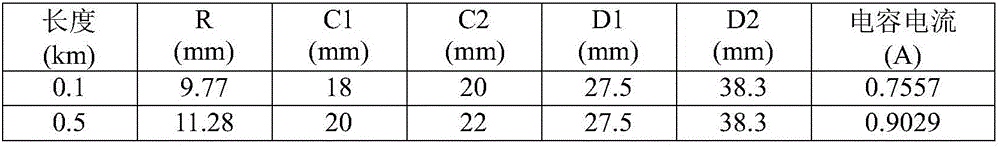

[0064] Taking the parameters of a 10kV cable as an example, the length L is 1km, R is 9mm, C1 is 16mm, C2 is 22mm, D1 is 28mm, and D2 is 40mm. Input the values of these 6 parameters into the obtained fitting model (you can set The function of model fitting is designed as a software for users to use, and the specific form in the software window is used to obtain 6 parameters), and the capacitive current is 1.6803A. According to this data, it is recommended to select an arc suppression switch with an arc suppression capability of 5A.

Embodiment 2

[0065] Embodiment 2 is to consider the operator's experience and environmental factors.

[0066] Still taking the above 10kV cable as an example, assuming a more serious situation, if the operator is inexperienced, the humidity in the air is 85%, the wind speed is 5m / s, and the temperature is 35 degrees, then the safety analysis software should be recommended according to the capacitance current. Select an arc suppression switch with an arc suppression capacity of 10A for live operation.

[0067] Correspondingly, the present invention also discloses a system based on the above method.

[0068] The 10kV medium voltage cable live working safety analysis system of the present invention is used to provide arc suppression measures for fracture arcs caused by excessive capacitive currents. The system includes:

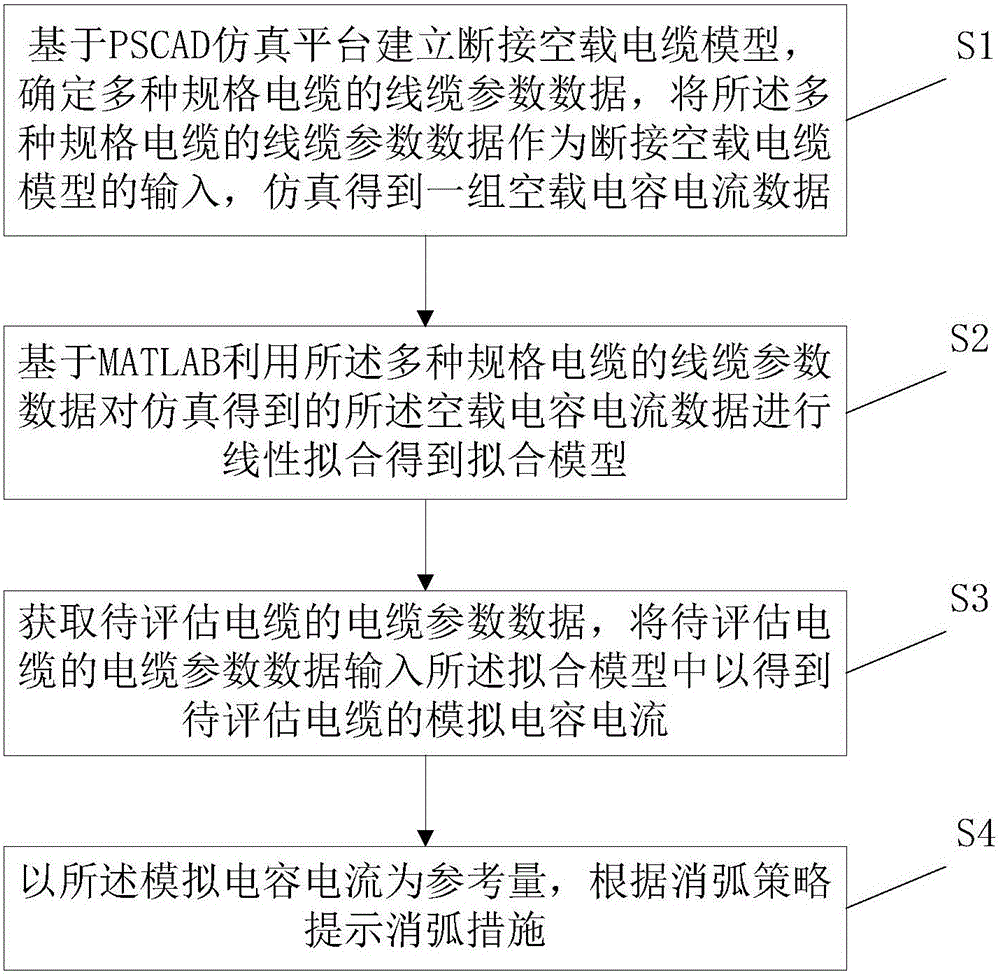

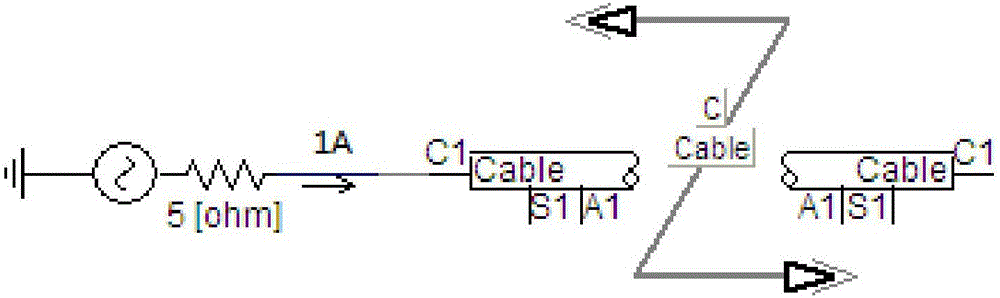

[0069] The capacitive current simulation module is used to establish a disconnected no-load cable model based on the PSCAD simulation platform, determine the cable paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com