Automatic tube penetrating machine and control method thereof

A control method and automatic threading technology, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of reducing production efficiency, installing more hardware 2, and missing hardware 2, so as to improve efficiency and prevent leakage The effect of pretending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

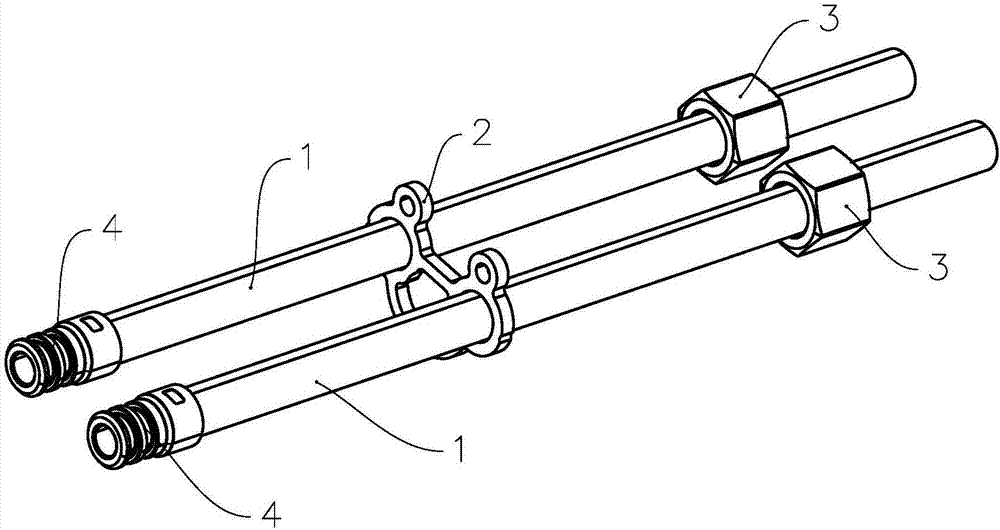

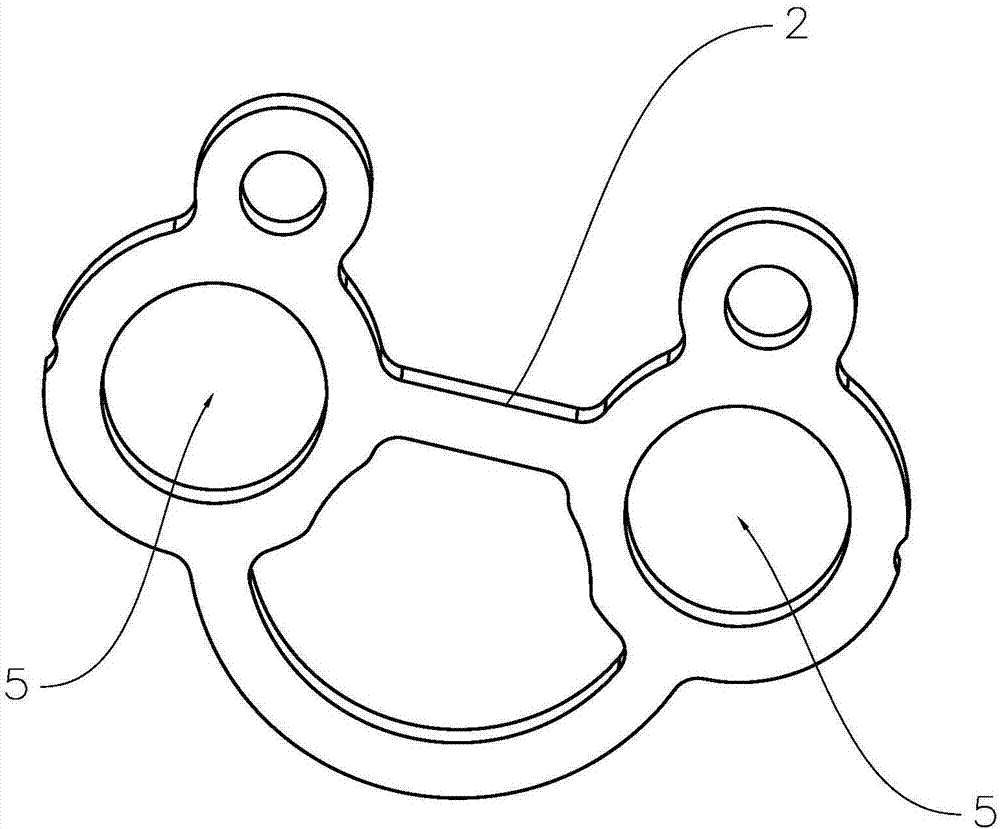

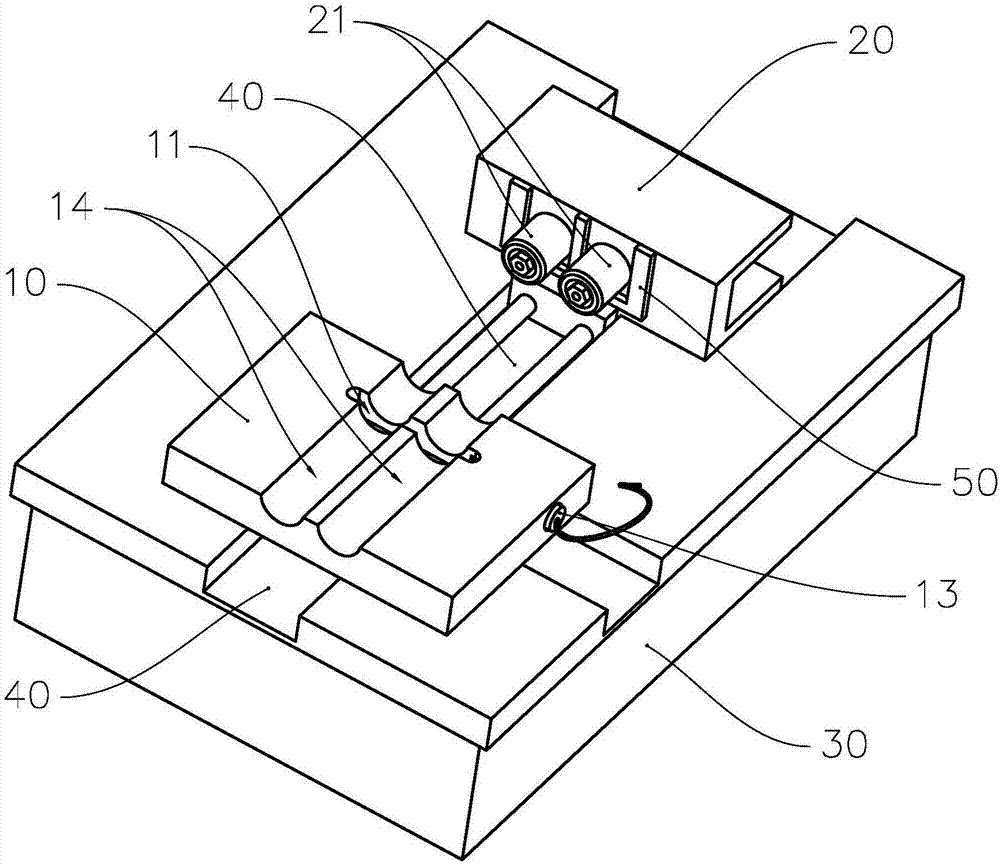

[0029] see image 3 with Figure 4 , image 3 with Figure 4 It is a structure diagram under different viewing angles of the embodiment of the automatic pipe threading machine of the present invention. In this embodiment, the automatic pipe threading machine includes a first fixing base 10 , a second fixing base 20 , a driving assembly and a control unit, and the first fixing base 10 and the second fixing base 20 are arranged on a workbench 30 . The first fixed seat 10 is provided with a first fixed groove 11, the first fixed groove 11 is used to install the hardware 2, the first fixed groove 11 is provided with a first start switch 12, the first start switch 12 is a photoelectric sensor switch, The photoelectric sensor switch is connected with the indicator light 13. After the first start switch 12 senses that the hardware 2 is inserted into the first fixing groove 11, it sends the first trigger signal to the control unit, and the control unit sends a control signal to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com