Lighter and integrally-assembled type gas guide assembly thereof

A lighter and assembled technology, which is applied in the direction of combustion and ignition, chemical instruments and methods, and igniters with fuel, etc., can solve the problems of low assembly efficiency, high waste rate of lighters, reverse foam pad installation, etc., and achieve vaporization Sufficient, stable combustion flame, and the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

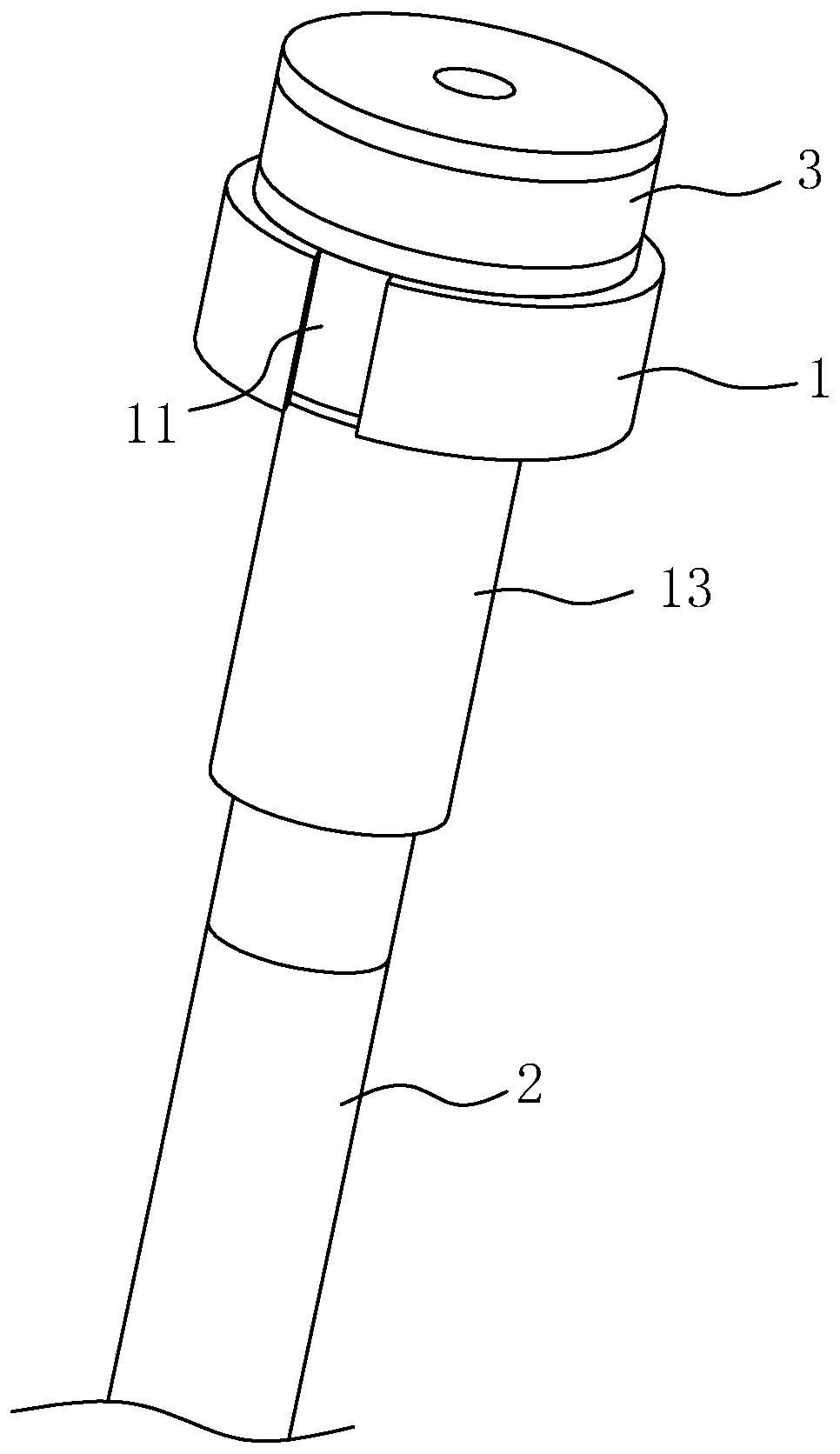

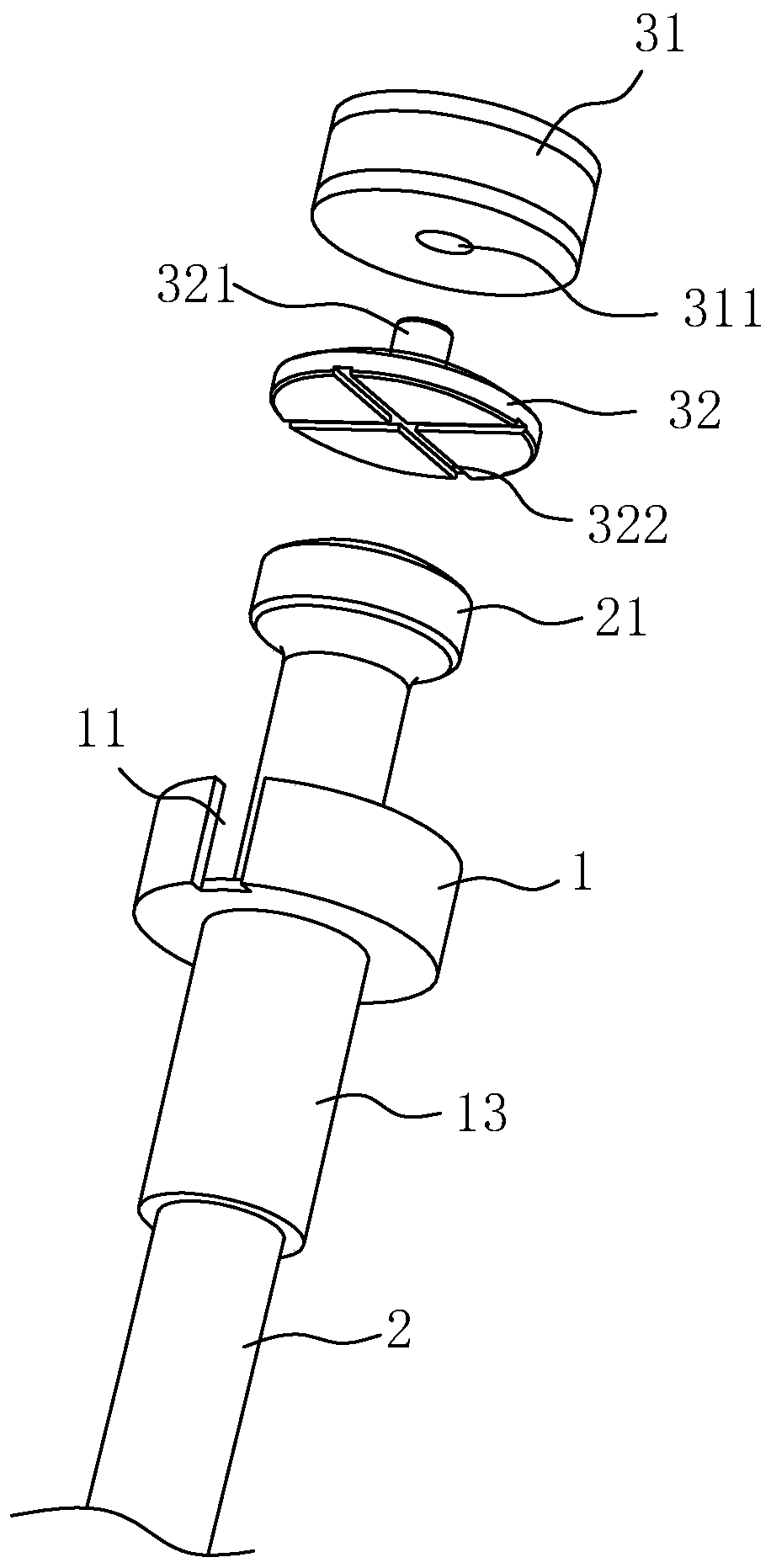

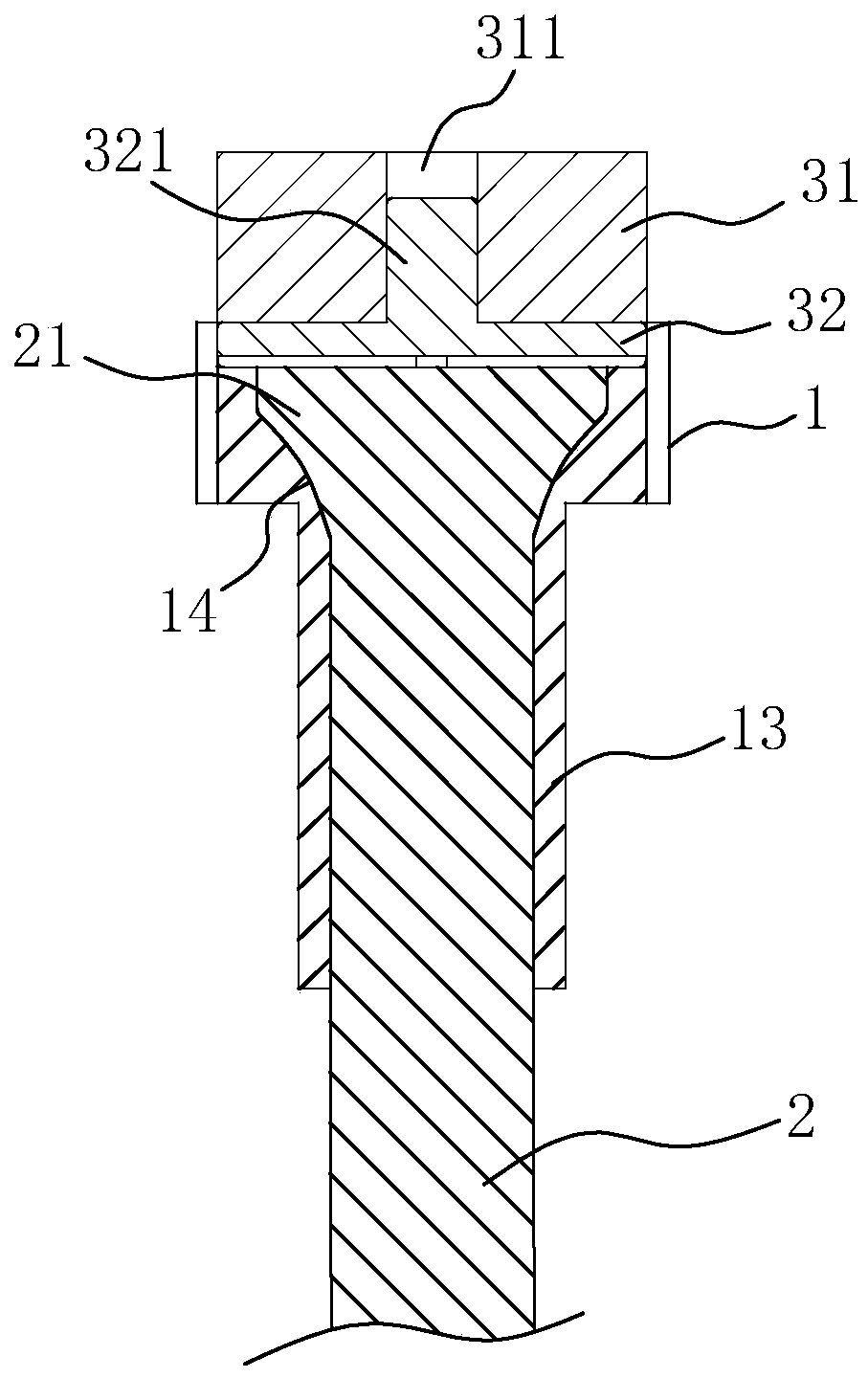

[0048] An integrated assembled gas guide assembly for a lighter, such as Figures 1 to 3 As shown, it includes: a metal sleeve 1 for assembling with the lighter body, and a ventilation structure is provided on the metal sleeve 1; a drainage core 2 that penetrates in the metal sleeve 1 and extends to the bottom of the lighter body, and is used to lead out combustible gas; And, the air filter assembly 3 embedded in the metal sheath 1 and located above the drainage core 2 is clamped and fixed with the metal sheath 1 .

[0049] Specifically, a metal sleeve 13 is provided at the bottom of the metal sleeve 1, and the metal sleeve 1 and the metal sleeve 13 are integrally formed. Both the metal sleeve 1 and the metal sleeve 13 can be made of metal materials such as copper, aluminum, iron, and metal alloys. The ventilation structure is an air passage 11 opened on the metal sheath 1, the air passage 11 runs through the side wall of the metal sheath 1 and extends from the upper end surfa...

Embodiment 2

[0054] The difference between this embodiment and Embodiment 1 is that: Figure 4 with Figure 5 As shown, in this embodiment, the air filter assembly 3 includes: a constant flow filter 33, and a snap ring 34 arranged above the constant flow filter 33 for clamping and fixing the constant flow filter 33, the metal sleeve 1 The upper end of the upper end and the clamping ring 34 are tightly clamped, and the constant current filter 33 is pressed and fixed. The clamping ring 34 is a metal ring. Of course, in practical applications, it can also be set on both sides of the constant current filter 33. The snap ring 34, through the constant flow filter 33, the combustible gas can be drawn out at a constant flow rate, so that there is no need to adjust the gas flow during use, and it is more convenient to use. At the same time, the snap ring 34 is locked with the metal sleeve 1 Connect to realize the fixing of the constant current filter sheet 33.

[0055] Moreover, a gasket 35 is al...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that: Figure 6 to Figure 8 As shown, in this embodiment, the metal sleeve 13 is not provided at the bottom of the metal sheath 1 to form a plane. At this time, the ventilation structure is also the air channel 11 opened on the metal sheath 1, and the air channel 11 runs through the side of the metal sheath 1. The wall extends from the upper end surface of the metal sheath 1 to the lower end surface, and the air channels 11 are arranged symmetrically on both sides of the metal sheath 1, or a plurality of them are evenly arranged around the circumference of the metal sheath 1, and the air is fed through the air channels 11 when inflated. , After the inflation is completed, the gas is released, which makes the flame of the lighter burn more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com