Plastic semi-finished product automatic edge folding and forming equipment

A technology for forming equipment and semi-finished products, applied in the field of automatic folding and forming equipment for blister semi-finished products, can solve the problems of low folding alignment, lower yield rate, low processing efficiency, etc., achieve high uniformity folding and shaping, and realize automation Operate and realize the effect of product collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

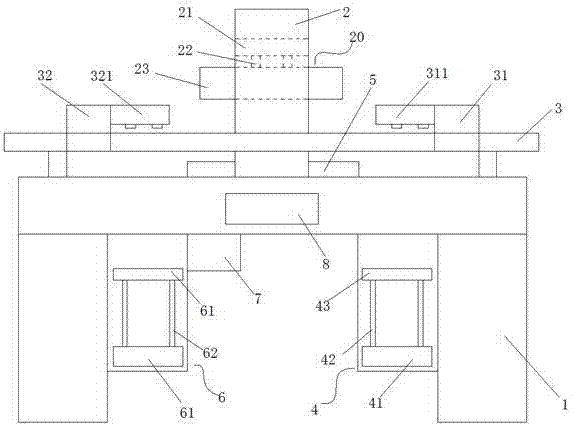

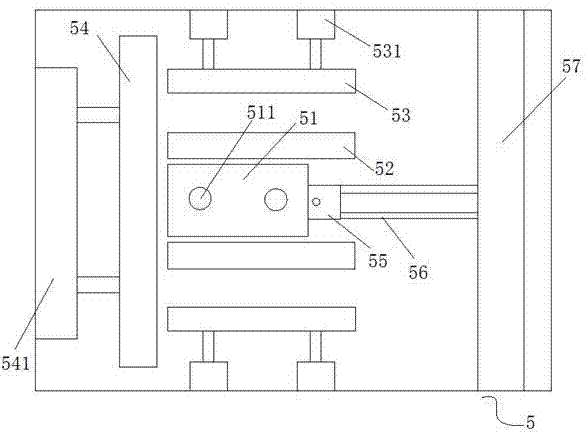

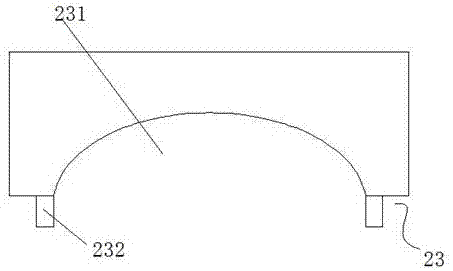

[0021] A kind of automatic folding and forming equipment for plastic-absorbing semi-finished products, including a frame 1, a positioning frame 2 is provided in the middle area above the frame 1, and it is characterized in that a positioning guide rod 3 is symmetrically provided above the horizontal plane of the frame 1, so that Both ends of the positioning guide rod 3 are symmetrically provided with a first translation mechanism 31 and a second translation mechanism 32; a feed mechanism 4 is provided under one side of the frame 1, and a Discharging mechanism 6, the middle area of the horizontal plane of the frame 1 is provided with a processing part 5, and the positioning frame 2 is provided with an auxiliary positioning device 20, and the auxiliary positioning device 20 faces the processing part 5; the first translation The mechanism 31 is connected with a first vacuum suction head 311, and the second translation mechanism 32 is connected with a second vacuum suction head 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com