Derailed vehicle quick resetting device and method

A reset device and vehicle technology, applied in transportation and packaging, railway car body parts, equipment fixed on the track, etc., can solve the problems of low safety factor and operation efficiency, affecting the smooth progress of production, and difficult control of displacement , to avoid equipment damage accidents, eliminate impact phenomena, and shorten repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

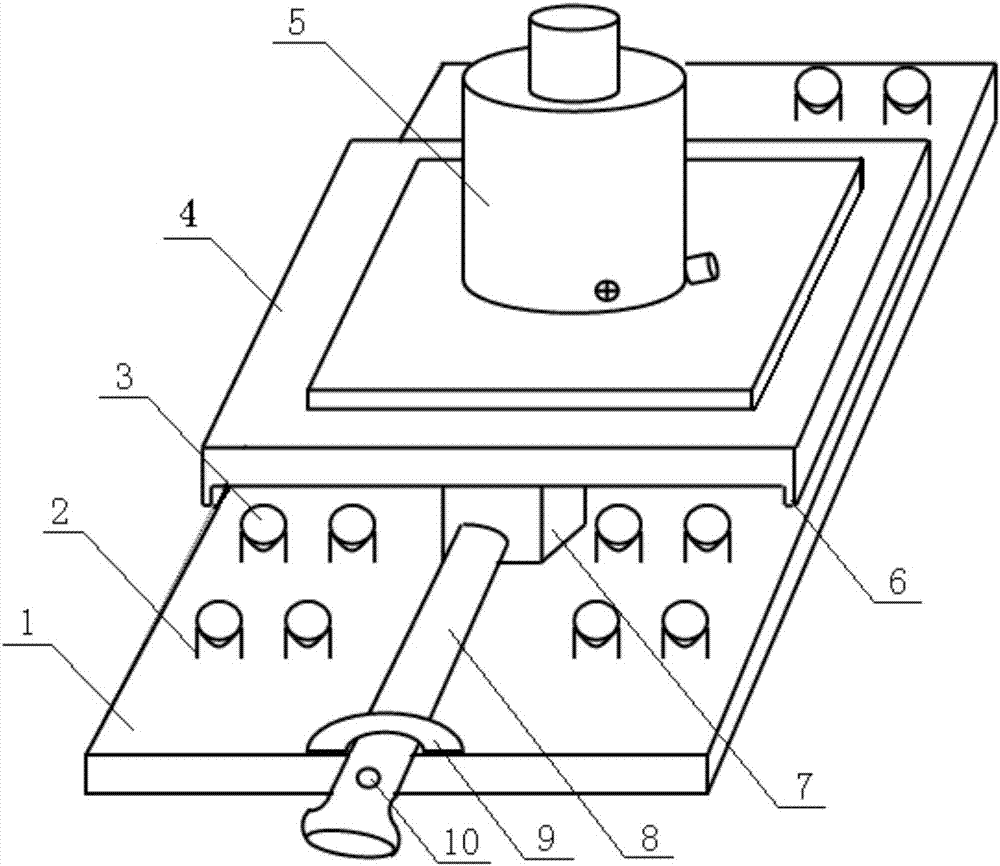

[0030] Depend on figure 1 It can be seen that the quick reset device for a derailed vehicle of the present invention is mainly composed of a base plate 1, a rolling body 3, a slide plate 4, a hydraulic crane 5, a screw nut 7 and a transmission screw mandrel 8. Base plate 1 is made of rectangular steel plates with a length of 550 mm, a width of 370 mm, and a thickness of 30 mm. A positioning retaining ring 9 is welded on the front end of the base plate 1. There are 28 positioning frames 2 evenly distributed on the upper surface of the base plate 1. The upper end of the positioning frame 2 has a Hemispherical bracket, rolling body 3 is housed in the bracket, and rolling body 3 diameter is the sphere of 40mm. A short cylinder or short cylinder with a length of 40-50 mm can also be used, and the corresponding brackets need to be modified accordingly, that is, the brackets are designed to be semi-cylindrical with both ends closed. The top surface of the rolling element 3 is higher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com