Roller washing machine and cleaning method thereof

A drum washing machine and washing machine technology, applied in the field of washing machines, can solve the problems of time-consuming and labor-intensive, unclean and thorough, and time-consuming, etc., and achieve the effects of reducing loss, easy cleaning, and not easy to adhere

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

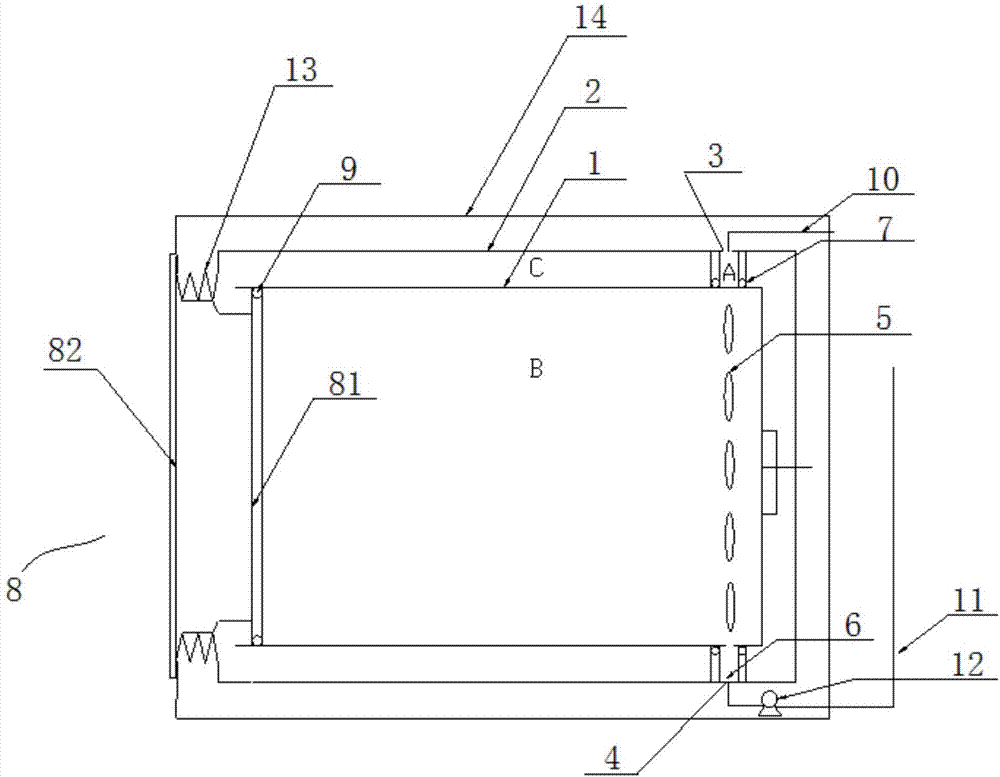

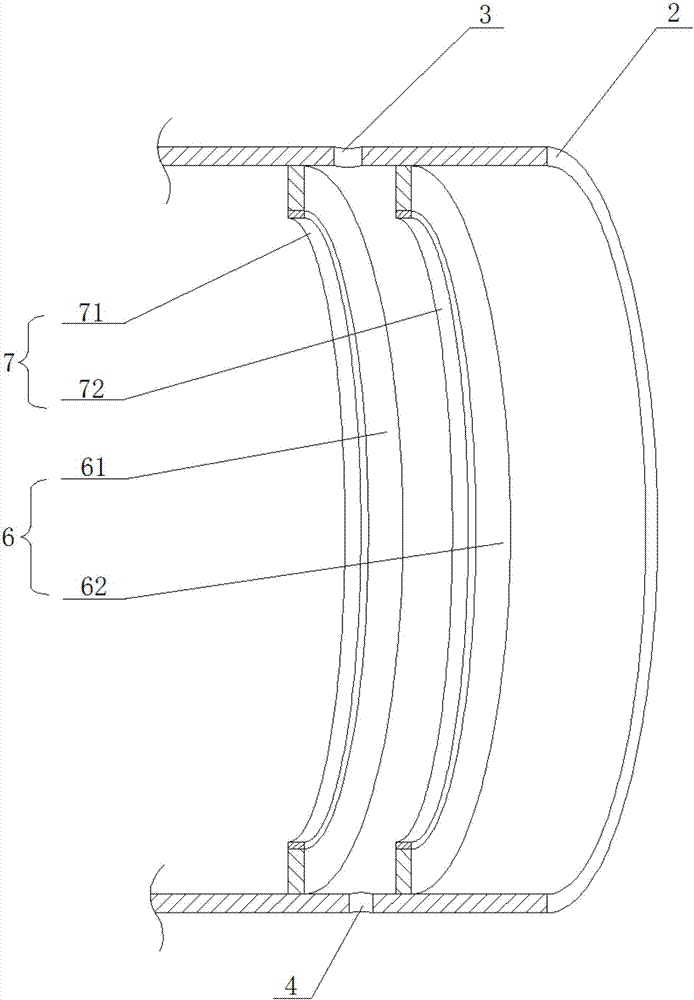

[0029] refer to figure 1 and figure 2 , In this embodiment, the drum washing machine includes an inner tub 1, an outer tub 2 and a drainage device. An annular isolation passage 6 is arranged between the outer cylinder 2 and the inner cylinder 1, and the annular isolation passage 6 is connected with the outer cylinder 2 or the inner cylinder 1. 1 rotation, also can be connected with outer tub 2 and keep still with outer tub 2 when washing. Further, the outer cylinder 2 is provided with a water inlet hole 3 and a water outlet hole 4 , and the water inlet hole 3 and the water outlet hole 4 are arranged in an annular area corresponding to the annular isolation channel 6 on the outer cylinder 2 . The inner cylinder 1 is provided with drainage holes 5, and the drainage holes 5 are arranged in the annular area corresponding to the annular isolation passage 6 on the inner cylinder 1, and the area on the inner cylinder 1 except the annular area corresponding to the annular isolation...

Embodiment 2

[0050] In this embodiment, the cleaning method of the drum washing machine in Embodiment 1 is described, and the cleaning method includes the following steps:

[0051] Open the drainage device, inject water into the annular isolation channel 6 , and discharge the water from the water outlet hole 4 on the outer cylinder 2 after washing the annular isolation channel 6 .

[0052] The annular isolation channel 6 of the drum washing machine has a small area and is easily rinsed clean. Through the above steps, the side wall of the annular isolation channel 6, the inner wall area of the outer cylinder 2 and the outer wall area of the inner cylinder 1 corresponding to the annular isolation channel 6 can be cleaned. The washing machine will not cause secondary pollution to the clothes during the washing process, and will not cause peculiar smells in the washing machine.

[0053] Further, when a shower device is installed, water is injected into the annular isolation channel 6 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com