Electromagnetic actuator, active vibration damper using the same, and method of manufacturing electromagnetic actuator

A manufacturing method and actuator technology, applied to electric components, non-rotational vibration suppression, manufacturing stator/rotor body, etc., can solve problems such as difficulty in confirming fixed parts and movable parts, high dimensional accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

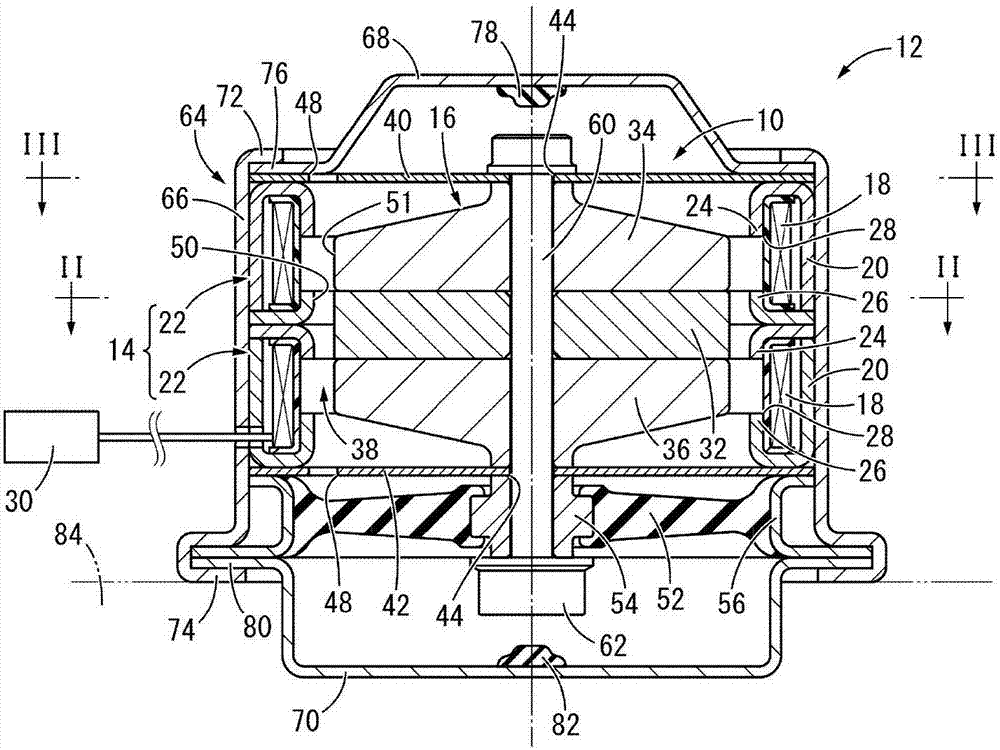

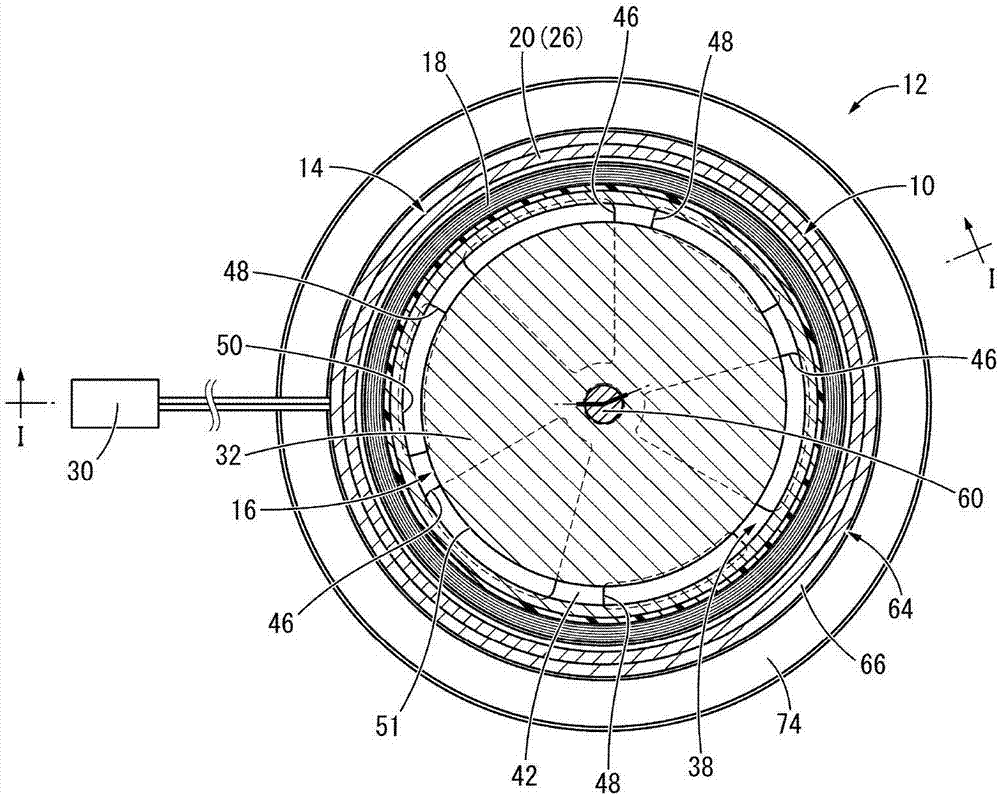

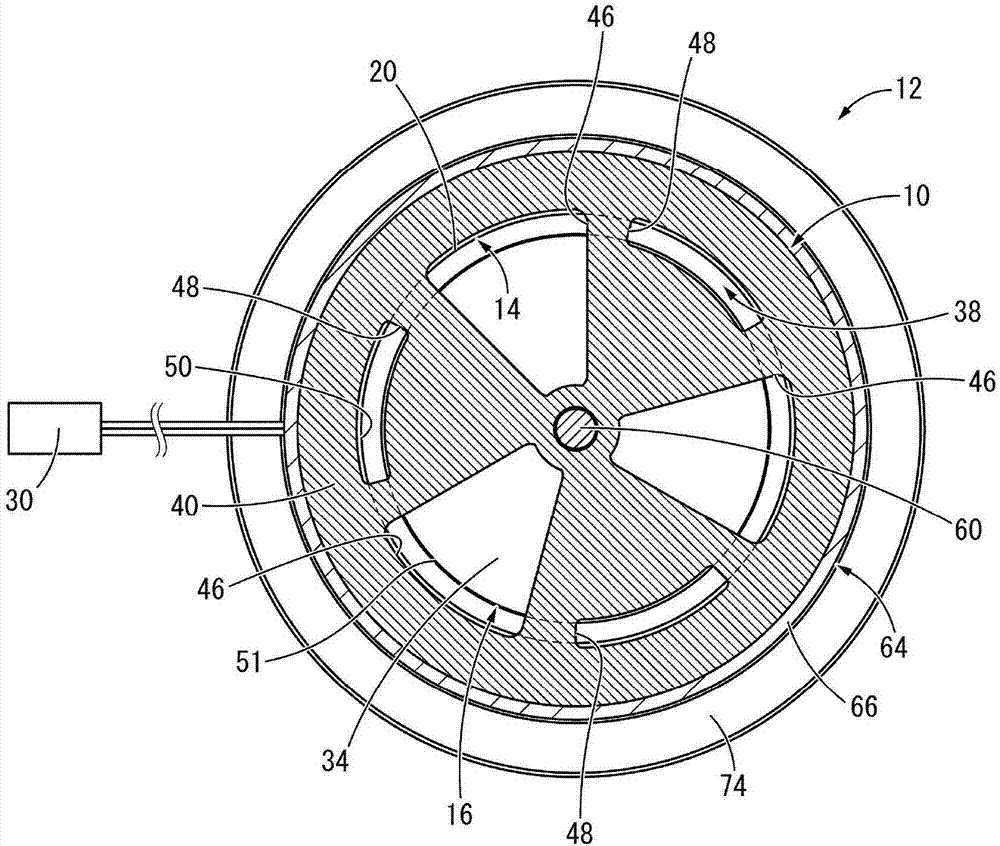

[0048] figure 1 , figure 2 In FIG. 2 , an active damper 12 including an electromagnetic actuator 10 according to the first embodiment of the present invention is shown. The electromagnetic actuator 10 constituting the active damper 12 includes a stationary element 14 and a movable element 16 that apply an exciting force to each other. In the following description, in principle, the up-down direction refers to the excitation direction of the electromagnetic actuator 10, and is also the axial direction of the active shock absorber 12, that is, figure 1 in the up and down direction.

[0049] More specifically, the stator 14 includes a coil component 22 in which the outer yoke 20 is assembled to the coil 18 . The outer yoke 20 is made of a ferromagnetic material such as iron, and is provided so as to cover the upper and lower surfaces and the outer peripheral surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com