Combined type gear motor based on oblique-tooth bevel gears and NGW type planetary gears

A geared motor, combined technology, applied in the direction of mechanical equipment, gear transmission, belt/chain/gear, etc., can solve the problems of limited application scope, uncompact structure, small bearing capacity, etc. Compact, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

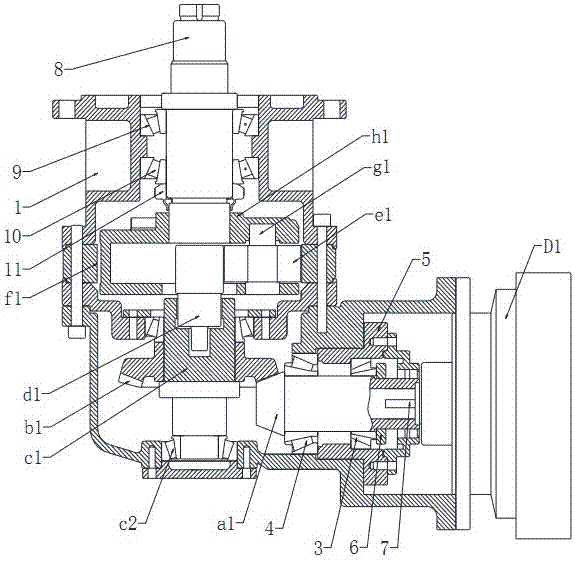

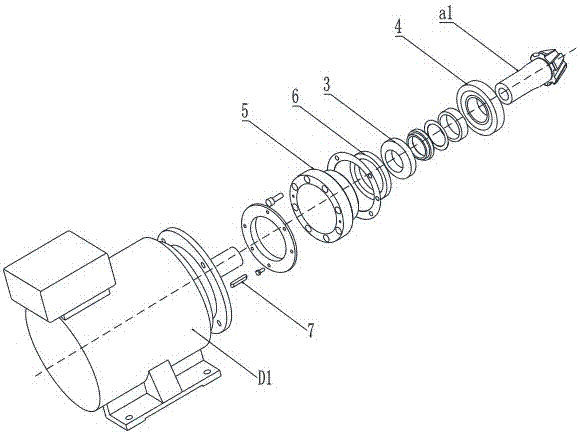

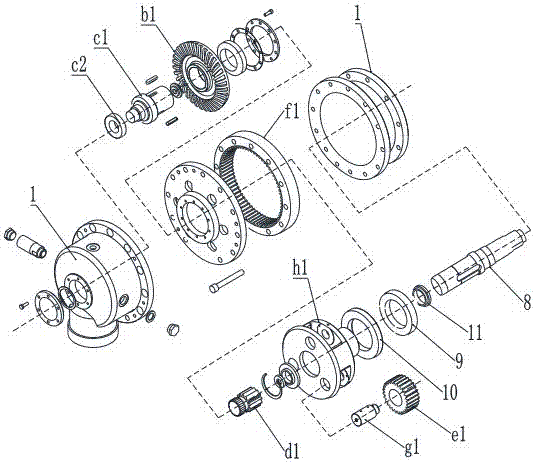

[0022] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0023] Such as figure 1 , 2 , 3 shows a combined geared motor based on helical bevel gear and NGW type planet, including motor D1, casing 1, bearing seat 5, active angle gear shaft a1, driven basin gear b1, central shaft c1, planet frame h1, planetary gear e1, sun gear d1, output shaft 8, one end of the motor D1 having an output shaft is connected to the casing 1;

[0024] The shaft part of the active angle gear shaft a1 has a hollow structure, which is sleeved with the output shaft of the motor D1 and connected to each other through the flat key 7; the bearing seat 5 is connected to the inner cavity of the casing 1, and the bearing The first tapered roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com