Cylindrical expansion tank for air source heat pump heating and manufacturing method thereof

An air source heat pump and expansion tank technology, applied in the field of cylindrical expansion tank manufacturing, can solve the problems of difficult docking between the air bag and the upper end cover, lower manufacturing efficiency, loose air bag, etc., and achieve the effect of increasing stability, improving stability, and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

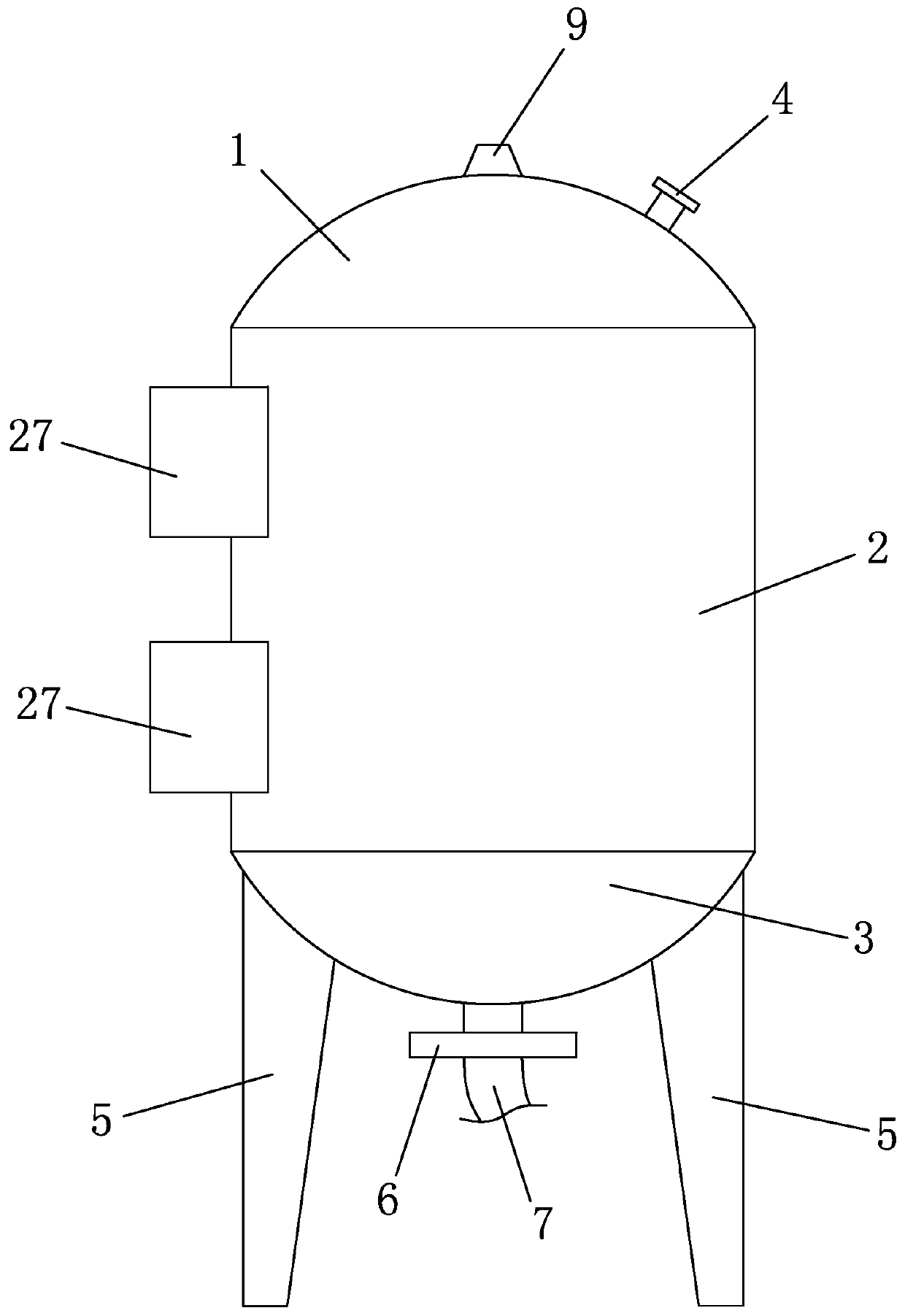

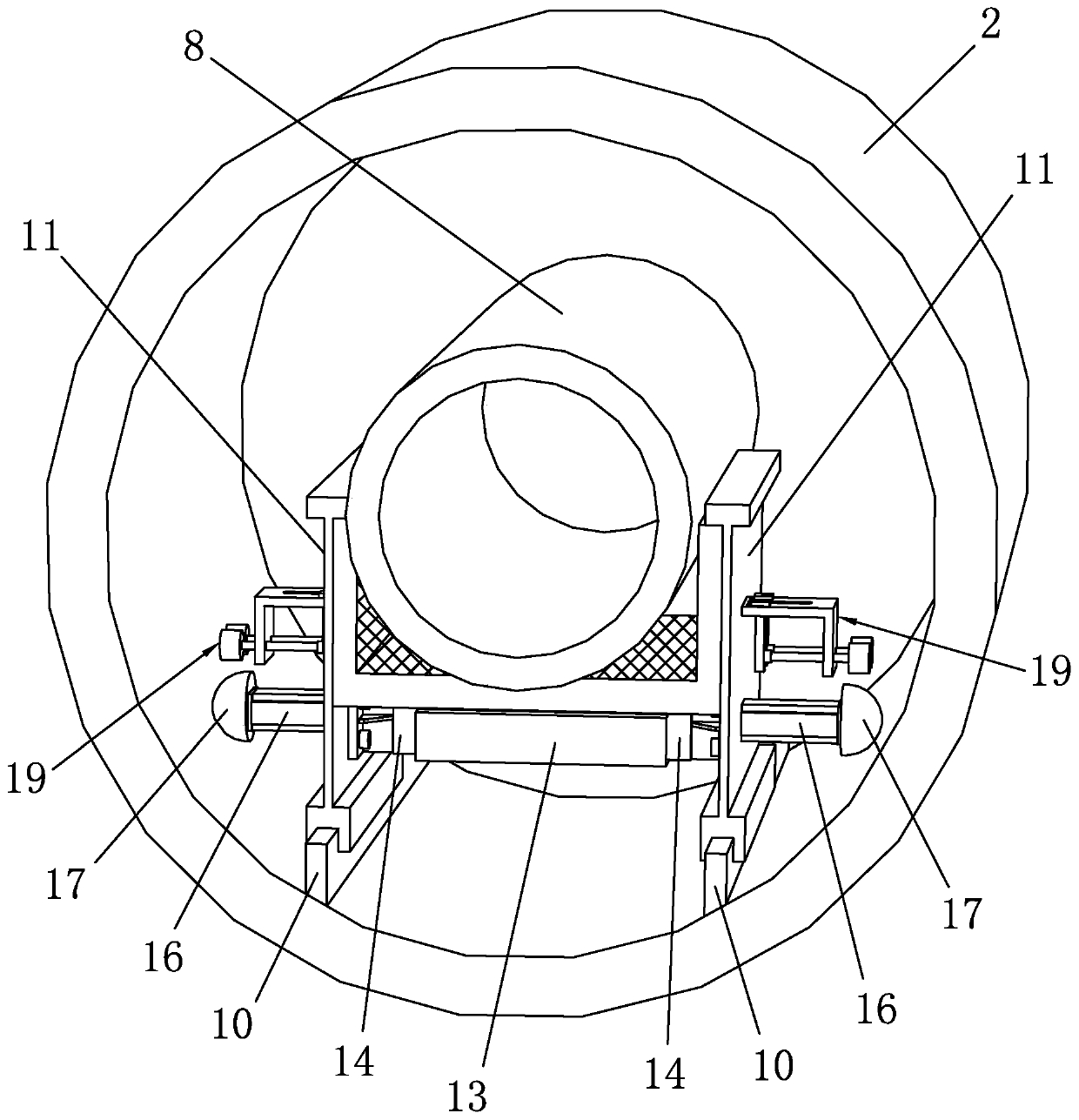

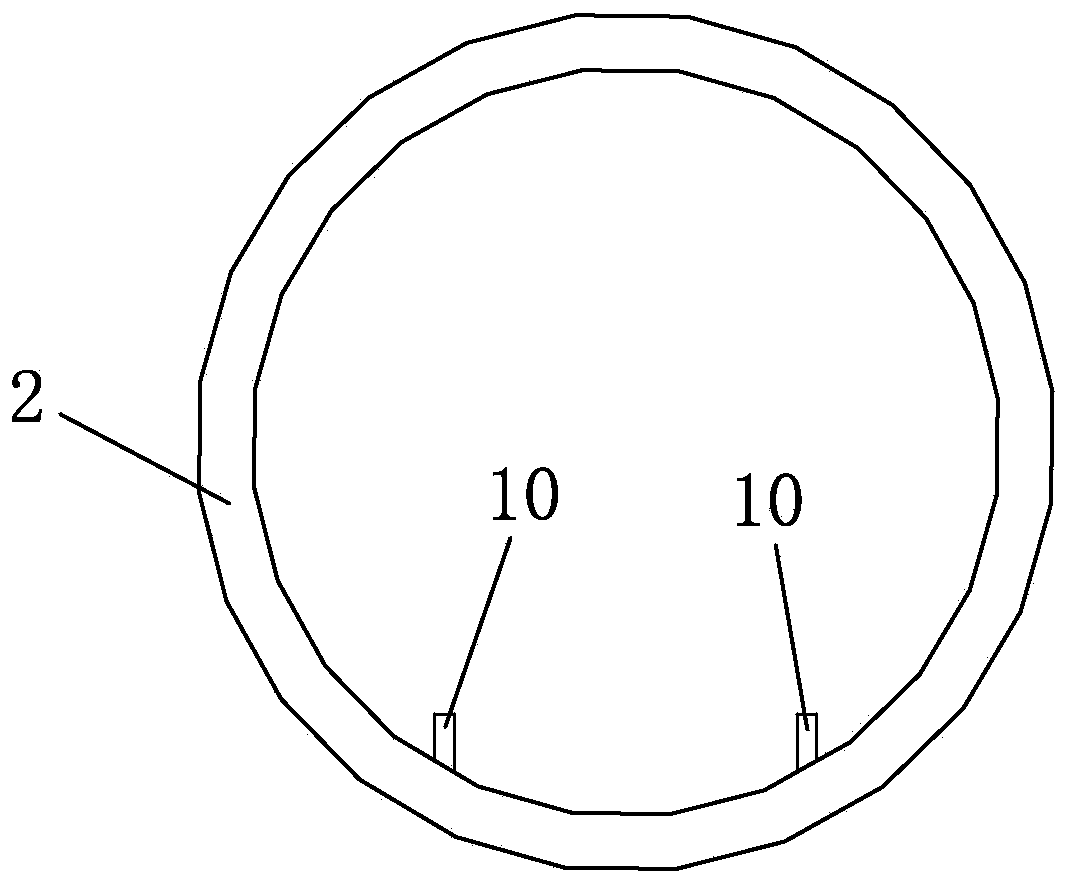

[0039] Such as Figure 1 to Figure 10 As shown, it is a cylindrical expansion tank for air source heat pump heating in the present invention, which includes an upper end cover 1, a cylinder body 2 and a lower end cover 3, the upper end cover 1 is provided with an air charging port 4, and the bottom of the lower end cover 3 is provided with legs 5. The lower end cover 3 is provided with a flange 6, and the flange 6 is connected with an interface 7. The interface 7 is connected to the container with a pump through a pipeline. The pipeline should be equipped with related components such as a pressure switch, a ball valve, and a check valve to avoid abnormal pressure in the system. Damage the expansion tank and other parts of the system at any time, and facilitate the detection and maintenance of the expansion tank and the replacement of the air bag 8 at the same time. The cylinder body 2 is provided with an air bag 8 , and the upper end cover 1 is provided with a fixing nut 9 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com